Posted by brian jones 11 19/09/2021 23:06:16

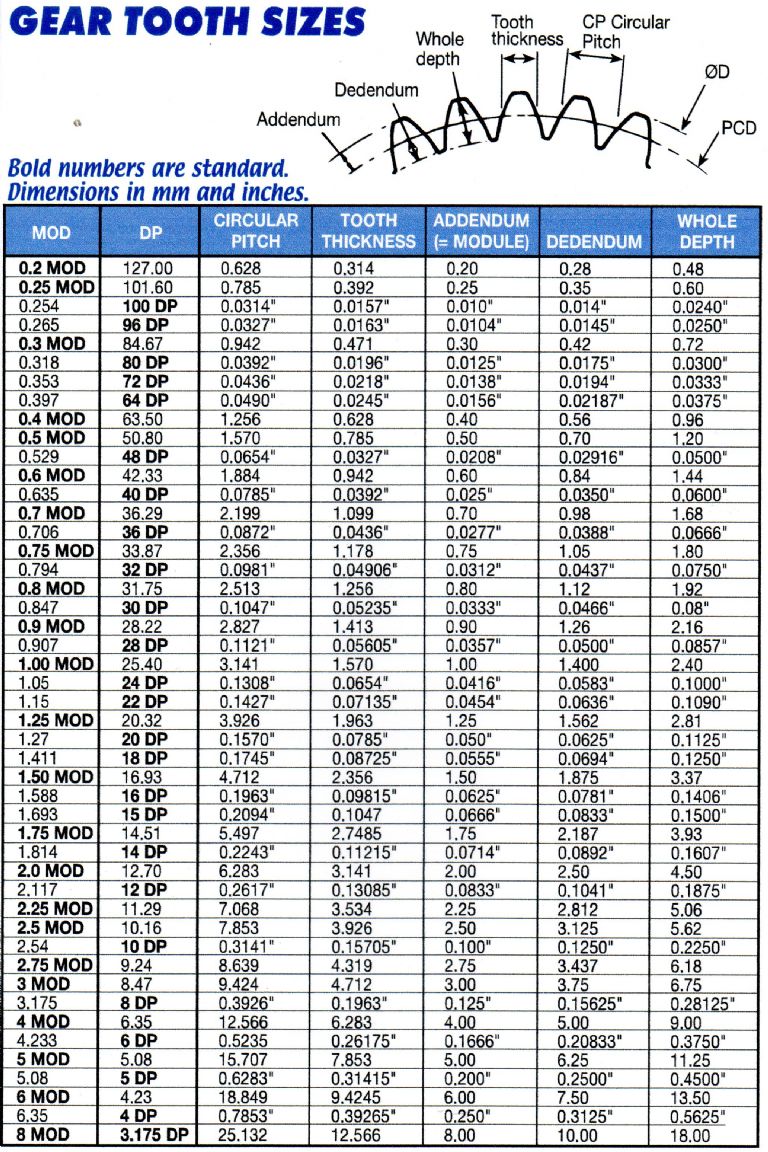

Why was the concept of DP Diametral Pitch introduced when the CP

Circular pitch addresses the same size issue and is physically

realisable ie you can measure it with calipers

———————————————————-

I expect it was more to do with the folk around at the time of his

avatar setting out gears with calipers and circles of whole inches.

Maybe it goes back further than this even to the time

of wooden gears in wind mills.

Although this does raise an interesting point for model makers ,

just like using stock size threads mostly all gearing is

Dp or module and made to a standard, for the production of

small gearing and rack type rotary cutters this does not make

much sense.For model engineering applications the only considerations

for gears would be to fit in the space available the required tooth count

and to look in the correct proportions it does not matter whether

they are mod or dp or cp standard.

Pitching out a 20 dp circular rack type cutter at .1571 inch is just

plain daft, since a cutter is being made it would seem to be

more sensible to use a CP system either imperial or metric

depending if that you favor one or the other units.

Laying out the spacing between each tooth can be so much easier

using this system .The page here

shows the near equivalent DP,CP ,MOD ,providing there is no intention

to link up to a commercial gear train there is little point in doing it from

a model engineering perspective.

Dividing also becomes somewhat easier from the example above of 20 dp.

eg for 20 tooth gear pitched out now at .150" CP instead of .1571 "

moving the cutter down by . 030 inch and setting the dividing head

to cut 100 divisions would ensure accurately timed cuts leaving just a

few facets on each tooth.Similar combinations of other size gears

just need to be worked out.

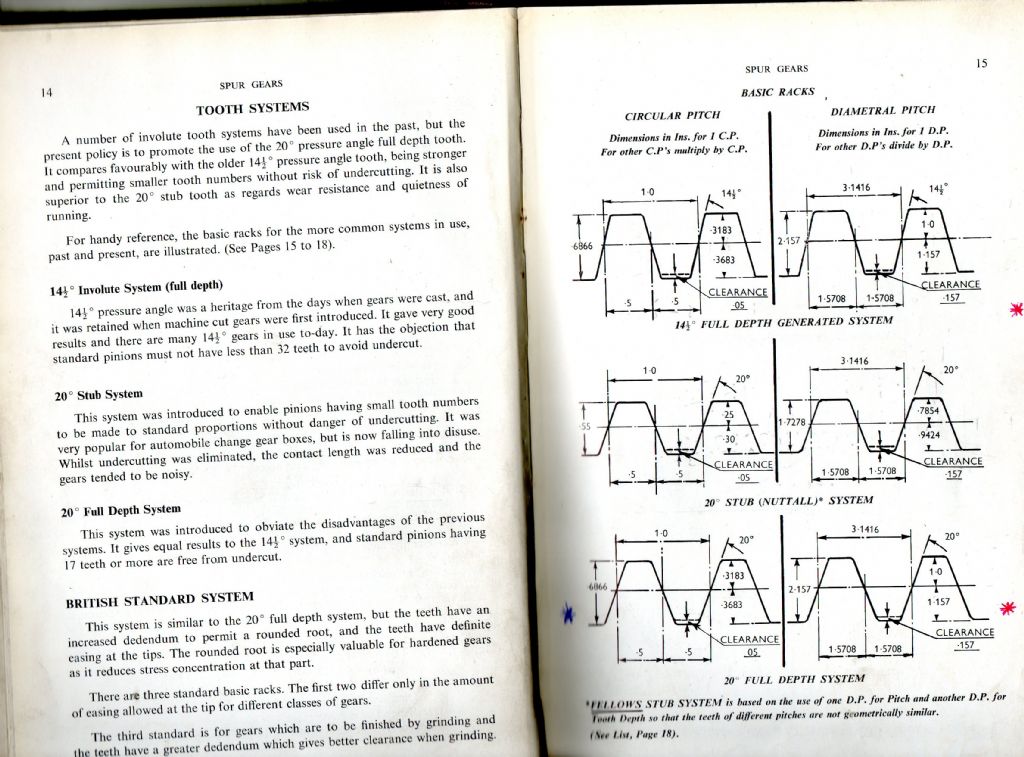

The chart here

shows the basic rack dimensions

and there is enough information there to calculate the tip width

and from that a form tool can be ground to make the cutter.

There is some benefit to having cutters properly form

relieved to avoid the type of finishes noted by

Roger Best in his posting 21/09/2021 21:57:52

"I did see some very good imitations of severely worn traction engine

gears. Modelling to such realistic detail is wonderful."

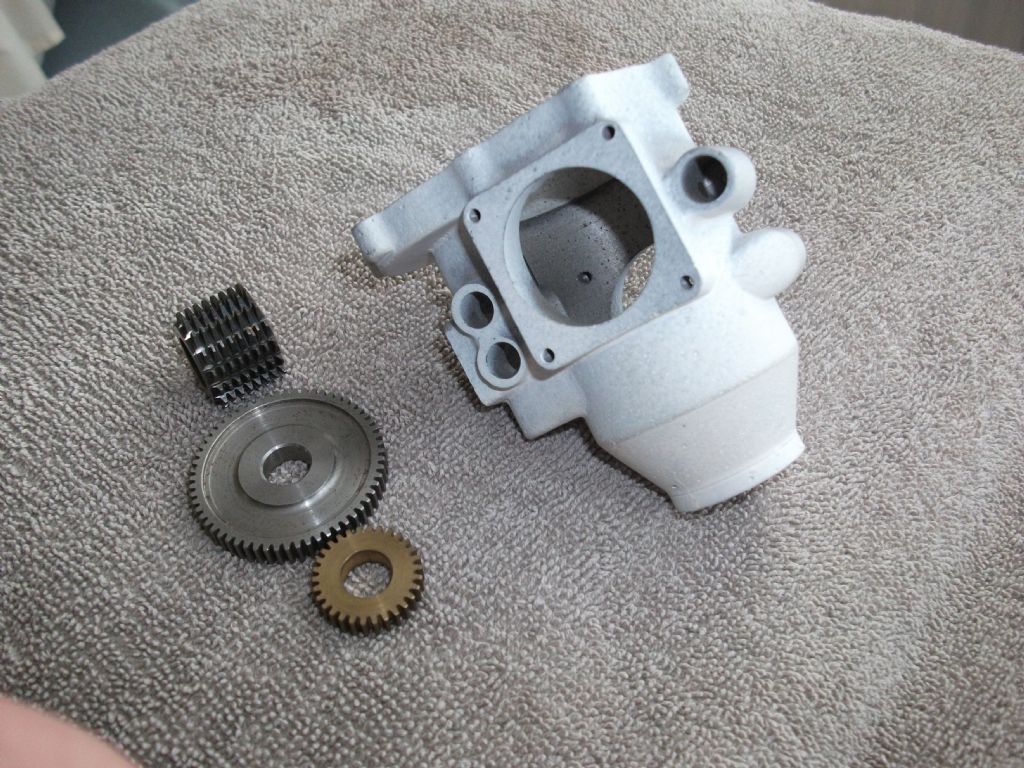

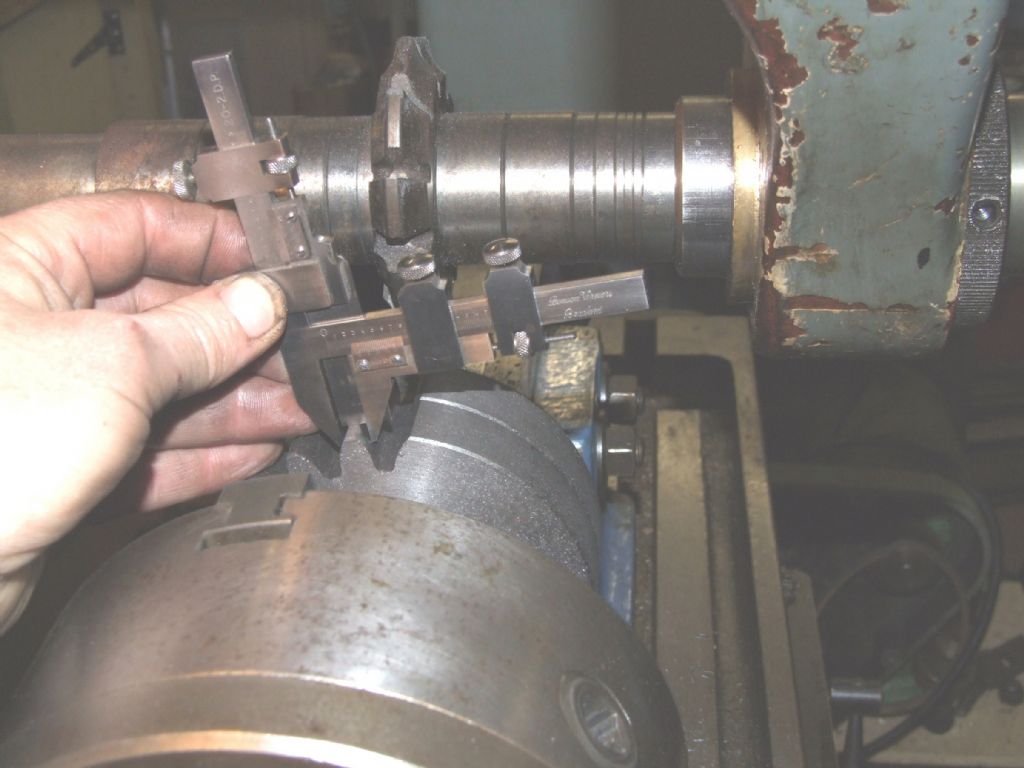

I made one of these circular rack cutters around 1985,because the

cutter had no form relief the cutting action was so poor i never

pursued the idea further,seen here a pair of

timing gears and a cast crank case it was never completed.

A few years later the Eureka device was published and provided

an easy solution to the making of form relived cutters.

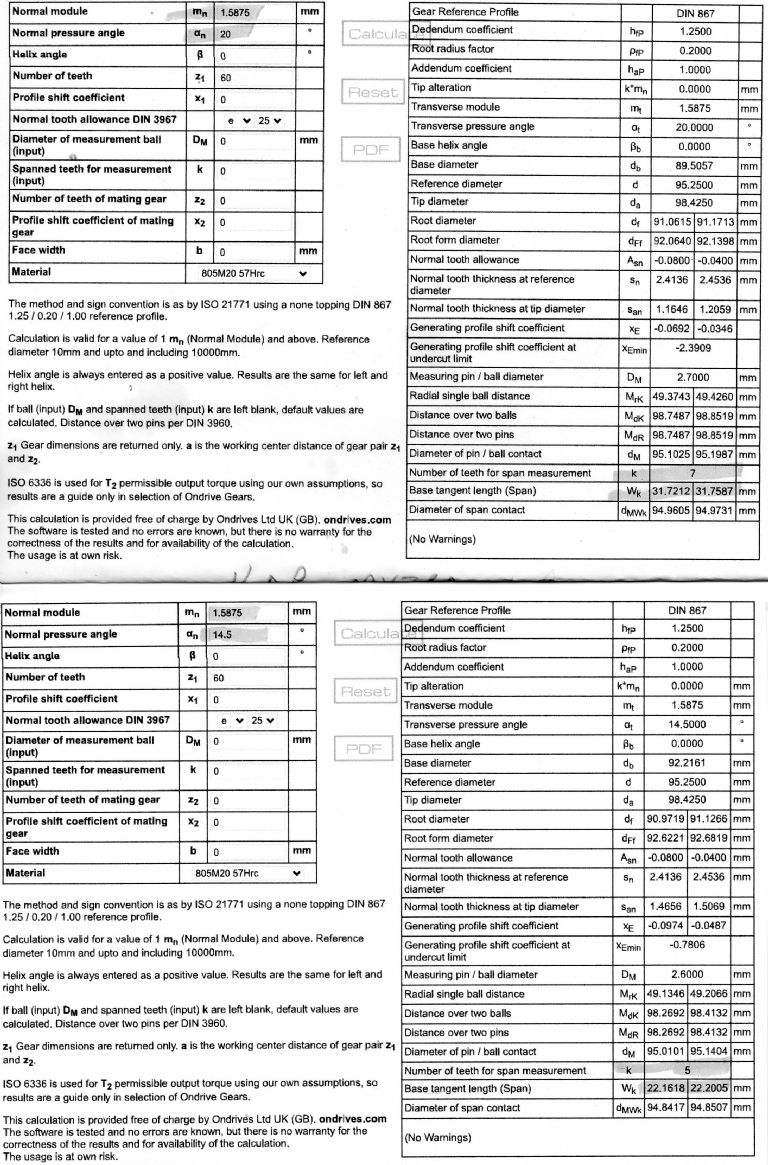

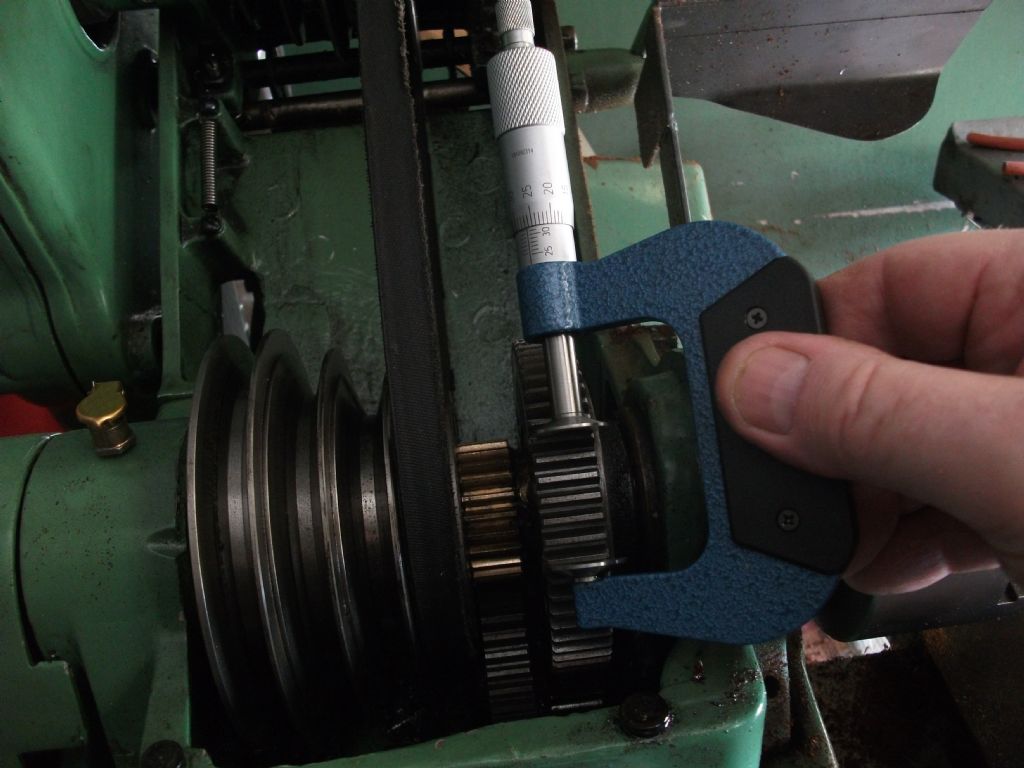

Look in at Lathes .uk the latest submission there is a

Micron gear hobber 102 a very interesting machine,

apparently will cut gears down to 800 dp.

In the section Brief General Catalogue 1960s-70s

shows the smallest gear in the world the profile of the teeth

looks remarkedly similar to BJ 11's gears.

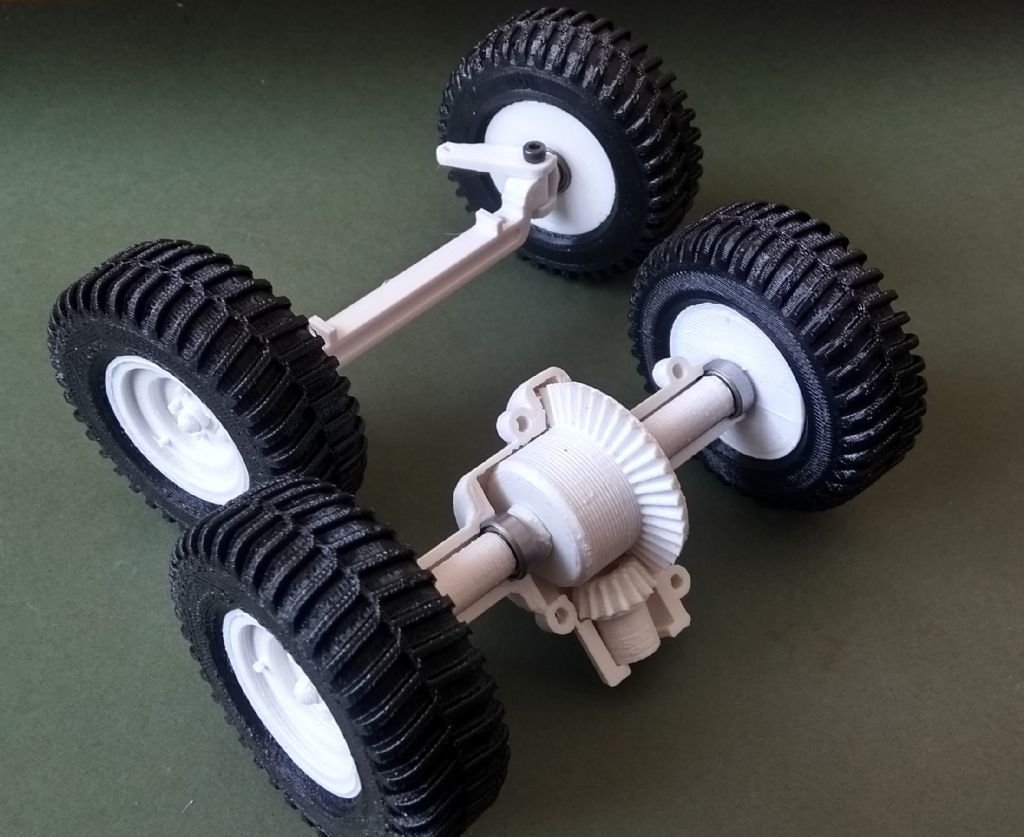

Finally with interest shown on here with horology and armchairs

maybe a combination project would be of interest.

John

Martin Kyte.