I see not having an Armchair has let Brian down again. Having found a copy of the most excellent Grossman's Lessons in Horogogy, he hasn't read it! The Grossmans, father and son, were scientists. They say:

Note the bit about the practical workman faithfully following 'the principles' in the execution of his work!

Armchairs as tools are valuable at the design stage and when things go wrong. Not necessary for repetitive work or following instructions. Interpreting a good drawing is quite easy; bad drawings stretch the poor old brain, which might need help from strong coffee or this forum!

Actually, the armchair isn't the best thinking tool available. I prefer a comfy office chair in front of a well-lit desk equipped with a computer, notebooks and pencils. At first the computer is used as a support tool rather than a thinking aid: they're good for reference; calculations; formal write-ups, and exchangeing ideas with friends etc. I learn best on paper taking notes from printed textbooks and start designs with rough pencil drawings rather than going straight to CAD. The computer is good later on at formalising and validating ideas, often exposing mistakes and allowing them to be corrected without too much aggravation.

Some problems are best thought out whilst walking, and I occasionally wake up with answers, presumably having processed them subconsciously overnight whilst asleep or doing something else entirely: like free-hobbing the 'not thinking about it' method can't be relied on though!

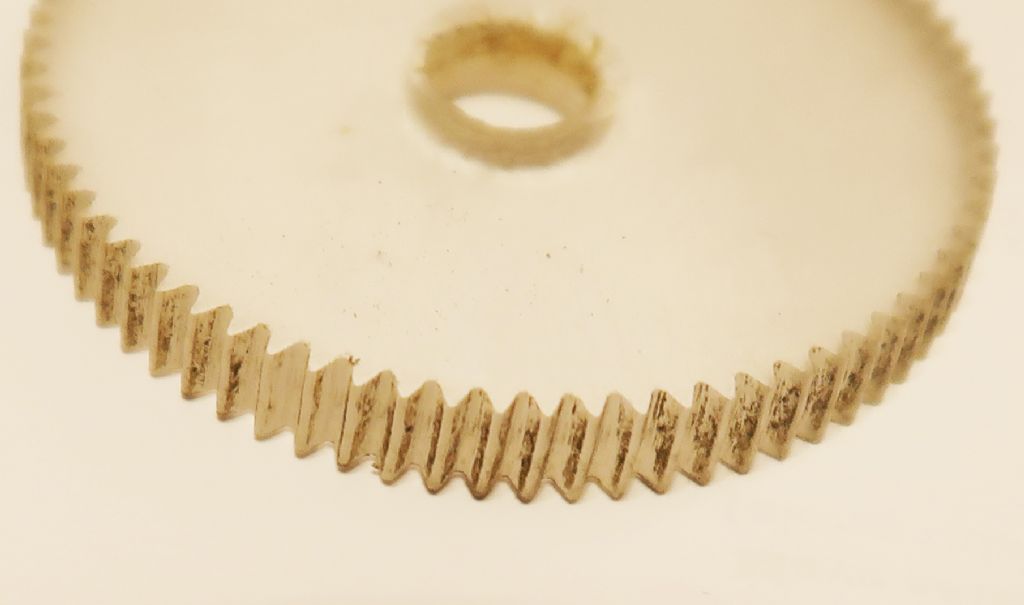

Going back to free-hobbing, a single gear, no matter how good looking, is useless. The acid test is making two or more gears that mesh together between designed centres. Free-hobbing struggles to do this and understanding why free-hobbing fails is an armchair job. No need to read Grossman, most shortcomings have been covered in this thread.

While free-hobbing isn't good engineering, Brian is congratulated for flushing out other methods of making gears. A thread that gets over 240 replies and 12000+ reads can't be all bad!

Dave

Edited By SillyOldDuffer on 23/09/2021 10:52:30

Martin Kyte.