My post were in answer to the original question asking for tips on hand sawing.

However as there has been some comments regarding more modern methodologies I make the following comments.

Hand fretting is quick to get going. All you need is the frame some blades and a sawing board plus a little practice and a good eye.

Full blown CNC involves a lot of development in terms of acquiring appropriate workshop machines and set up's and is certainly worth while if you wish to make clocks in batches and in reasonable numbers. One offs and ocasional clocks you may question the outlay in cash and time.

My late freind Chris Sangster spent some years developing his approach to clockmaking. I guess it really sprang from a combination of disliking the process of crossing out, a desire to produce small runs of 3 or 4 clocks at a time, and an interest in the then 'new' approach of CNC in the home workshop.

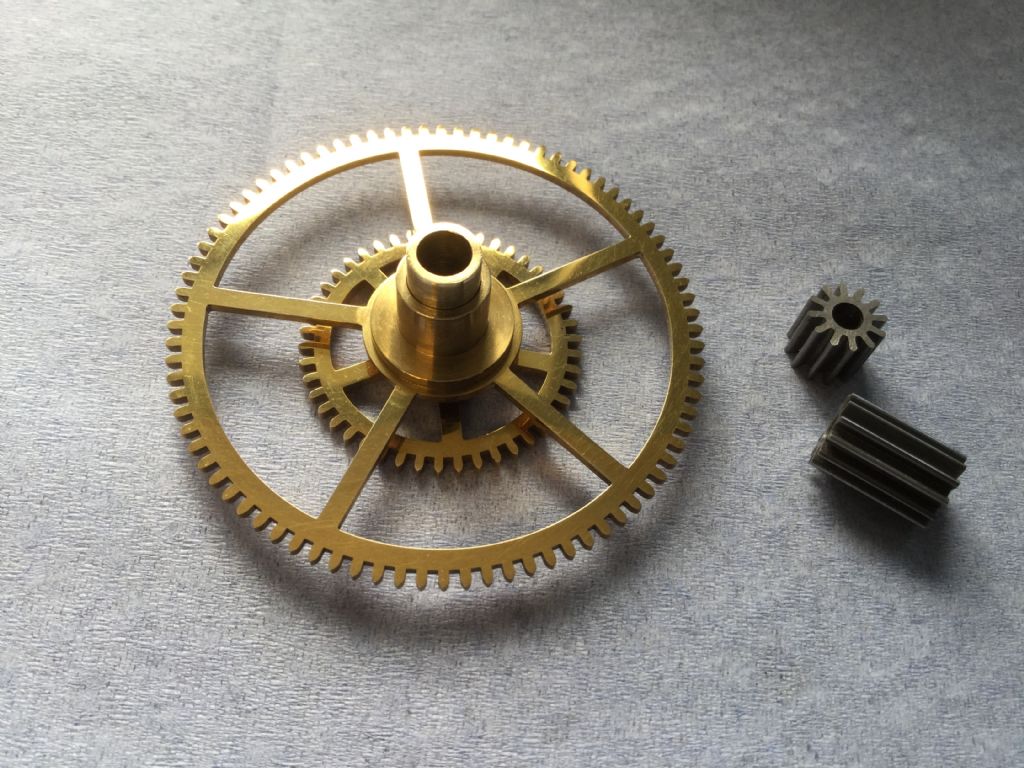

Initially Chris, who was a draughsman by profession, started to use a rotary table on his Myford VME mill to mechanise the process of crossing wheels. With the wheel drawn out and co-ordinates established this worked reasonably well. At least sufficiently well for him to feel it was preferable to hand sawing. The filing and finishing still had to be done though.

The next move was to 'CNC' a Seig SX1 with the addition of steppers and replacing the head with an engraving spindle fast enough to drive 1mm router cutters. Software was from a free download developed by another clock maker who's name is now lost (at least to me) Blanks were held with double sided tape and the setup produced wheels with very little filing required except nicking out the corners.

Eventually the Myford headstock dividing head was motorised along with the leadscrew of the lathe and with the overhead drive automatic tooth cutting was achieved. The final move was planned to be a flatbed router capable of engraving faces and chapter rings which was sadly uncompleted at the point of his untimely death.

All in all I would say this was at least a 15 year process in development. Now I'm sure things could be done far quicker than that but realistically 18 months is not unreasonable and you are going to require at least 2 or three grand starting from scratch.

So to finish, you can do anything from Hand cut to CNC and all ports between but the more complex you go the more you have to invest in your workshop kit, and your time and money. Think about what suits you.

regards Martin

Chris TickTock.