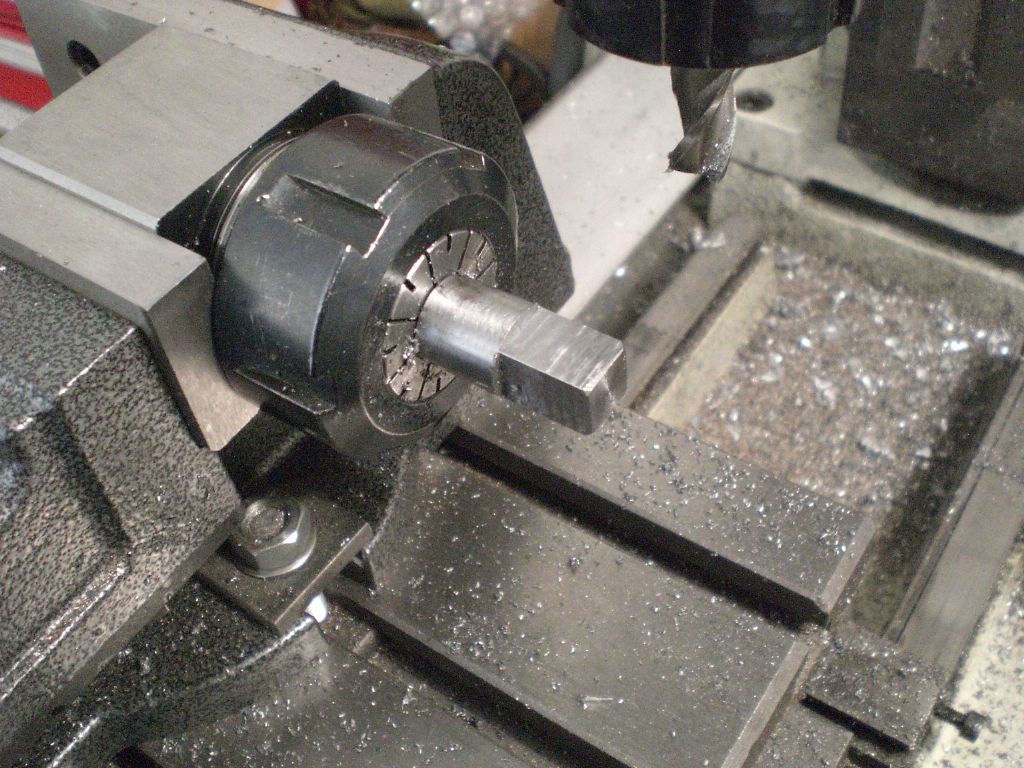

For anyone dubious about holding an End Mill in a three jaw chuck; think on this!

In 1958, my chain smoking Turning Instructor showed me his cigarette lighter.

"Made that on nights during the war"

"But you were on lathes, and it is rectangular,"

"Clamp the job in the Toolpost and put an end mill in the chuck"

He was nearing retirement and had been making his living on piecework, so knew a thing or two!

Make a block or pillar, to fit between the underside of the jaw and the lathe bed, to set it horizontal. A simple turning and facing job ) )

The starting point is the end of the bar being turned down to just less than the corner to corner dimension. That puts the required corner relief in place before you start filing the flats.

I am assuming that a newbie may very well not have a Mill.

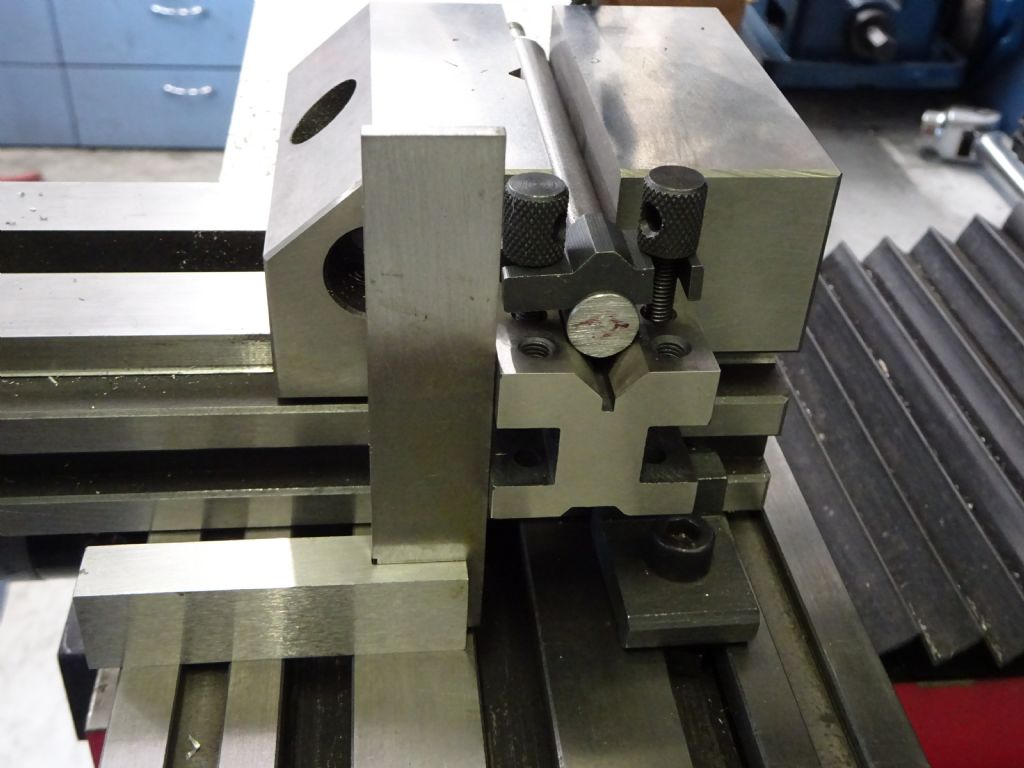

If one is available, then use a Stevenson square collet block, or having made it, set the first flat vertical with a square, to mill the second and repeat for subsequent flats.

HTH

Howard

Nigel Graham 2.