Posted by Calum Galleitch 06/03/2022 13:52:11

As a milling machine is not an option for the foreseeable, I'd like to undertake light milling operations

in the lathe as well as other operations involving attaching things to the cross-slide. However, the

cross-slide on my lathe is not big enough to consider adding T-slots. In the long run manufacturing

a replacement cross-slide would be ideal, but I'd need both a big enough mill and the skills to do it!

So my thought is to make a fixture plate in aluminium which would be bolted to the cross-slide.

I don't require repeatability of fixturing, I think, so the aim is purely to create a secure platform

to hold things down.

The cross slide is something like 350x120mm: so my first questions are: how thick

should the plate be, and how securely should it be attached, to be reasonably rigid?

Recognising of course that "rigid" is a relative concept! I don't imagine myself milling

to accuracies of a tenth: more like holding a vertical milling slide to make things like

T-nuts or a QCTP. I was thinking that six mounting holes in total would be adequate,

in the corners and half-way along.

Looking online I see I can get a bit of 16mm plate for about £35. I am thinking

of an array of tapped M10 holes at say 30mm centres – does this seem

reasonable? Or would it be simpler and more flexible to just drill and tap

holes as and when I need them?

Tap drilling aluminium: I may be looking in the wrong places but aluminium

drills in 0.1mm increments don't seem to exist. I can find an 8.8mm carbide

stub drill on eBay: to go through say 16mm, will this be up to the job for say 40-odd holes?

——————————————-

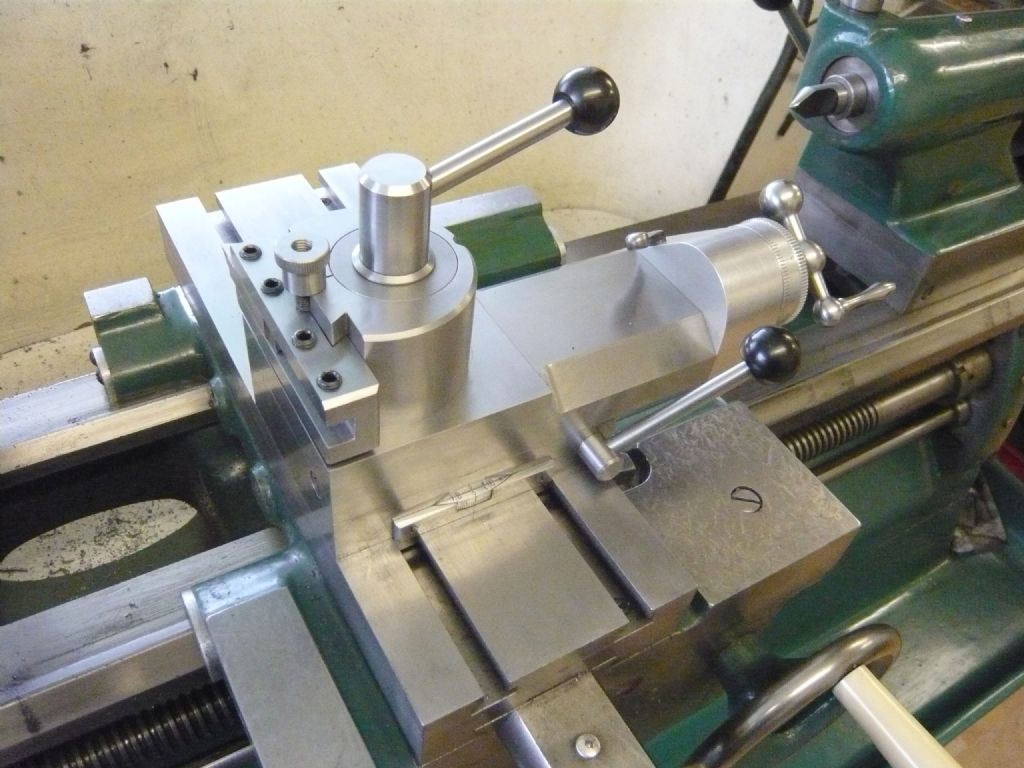

I have the similar machine to the Cub 750 in the Warco GH 1000 ,i also have plate

mounted as in the photo here it is 15 " long 6" wide and 1" thick at its machined size.

There are only 6 off 6 mm cap head screws to fix it.

I think you will need to re think the "I was thinking that six mounting holes in total would be adequate,

in the corners and half-way along" .

as you will find the cross slide at the back end is just a thin shell to cover the lead screw over

a length of about 4 inches and will not provide much of a secure fixing.

The cross slides on these machines are not that rigid ,a thick steel plate would be more

the thing to go for if you are unable to machine a cast plate as i have ,the aluminium

plate will add little to the rigidity of the cross slide.

John

Bill Phinn.