So, I'm now more confused.

To recap, I'm trying to tram the mill in order to get a good finish and an accurate cut (I want to be able to make parallel sides!).

I believe that the mill table slopes downwards to the front and I've found (surprise) that the column's a bit tilted.

I put a 0.1mm feeler gauge under the front way which made the table level within 0.01mm front to back. by dint of bits and bobs of feeler gauge I got the spindle square on to within a tad over a though over a circle with a 105 mm diameter – pretty close to flat front to back and a fall of .04mm on the left.. Which I thought was quite good for a micro mill. I've nothing in the half though region which is what I'd have needed to tune it up more.

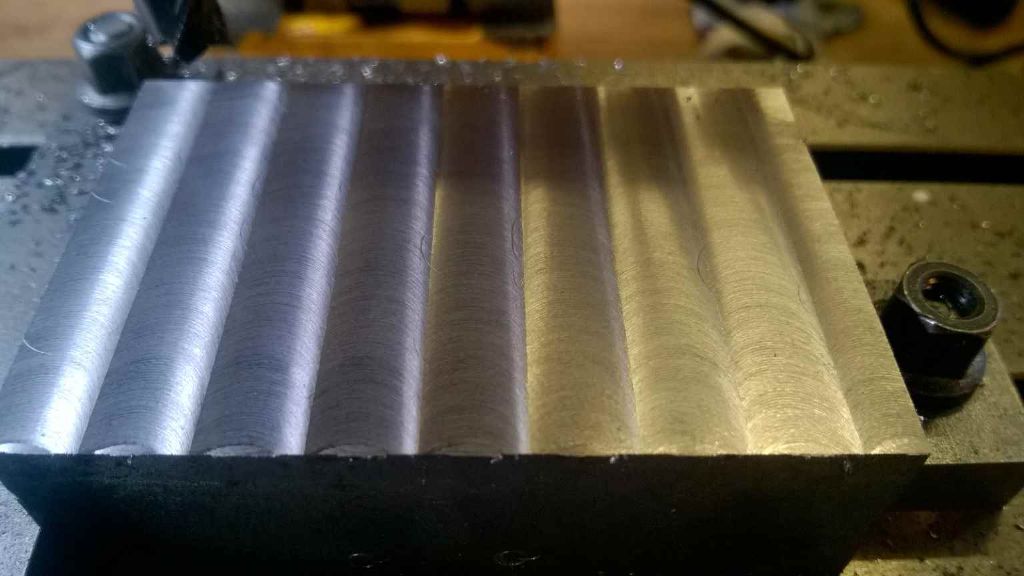

Then mounted my test block and faced it. 10mm carbide cutter, approx 0.1 depth of cut, 2000rpm and around 4mm / sec feed.

Although the picture looks a bit imperfect I was quite pleased. The metal feels smooth with the ridges in the front back direction barely discernable by touch. a dial indicator gives a tick of about .003 / .004 mm when it runs over them. The piece (50mm x 80mm) was level across the short face, but rose about .07 mm to the right, which is more or less consistent with the tramming results

Then i tried the same cut (0.1 mm) in the other direction. This was a disaster!

Before I panicked entirely, I re-did the face with the original direction and got the good results I had the first time,

I 'lapped' it with some 800 abrasive paper on my surface table which removed any visible tick for the ridges. though they are still visible – I ran out of paper before finishing.

Now this is where things get wierd. I was going to try and remove the .03 mm tramming error. I replace the dial indicator arrangement and re-checked the tramming. Now it appeared to be out on the left by .03 mm but in the opposite direction.

I thought, 'perhaps its where abouts it is on the table' so I moved the table to the far left (reading on right of table) and took a reading.

Somewhat to my surprise the table now falls ,2mm to the front and falls .08mm on the left. And this is now consistent. I've moved the table all the way to the left and at all points inbetween I can the same reading (~0.2 and 0.08 mm out), Th table now falls by about 0.03 which is worse than before the movement.

I do have a theory for all of this which I wanted to pose to the experts! I think the issue is around the 0.1mm feeler gauge under the ways which I'm using to raise the table. I think that the way is not running smoothly on it which is why the left right cut is so poor. And I think it's moved around a bit which is why the tramming's gone out.

How should I properly level the table? I would guess I would either have to get a better shim, or scrape or lap the far way.

I'd appreciate any practical advice on how to accomplish any of these tasks!

Iain

(P.S. Sorry this is so long!)

Iain Downs.