As no one else jumps in, let me try. I own a K1 since about a month. AFAIK there are two models, the smaller K1 and the larger (and more expensive) K1Max. My impressions so far: It is the fastest and most precise printer I ever saw (ok, I haven’t seen all of them). It needs no manual leveling of the print plate, all is done automatically.

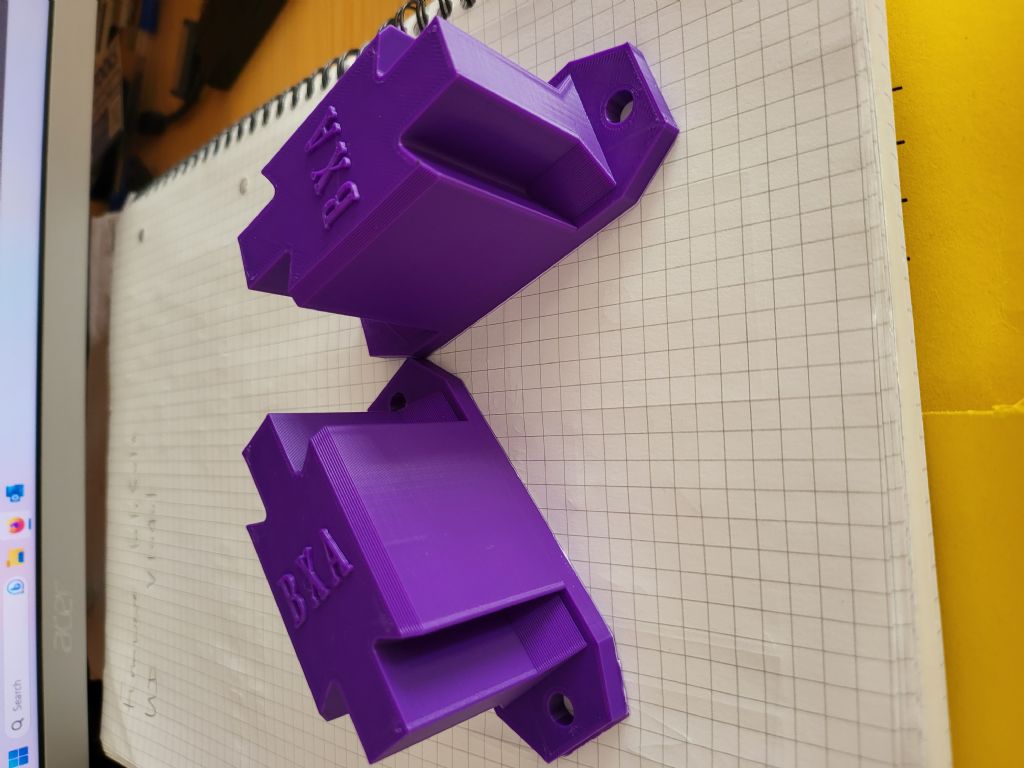

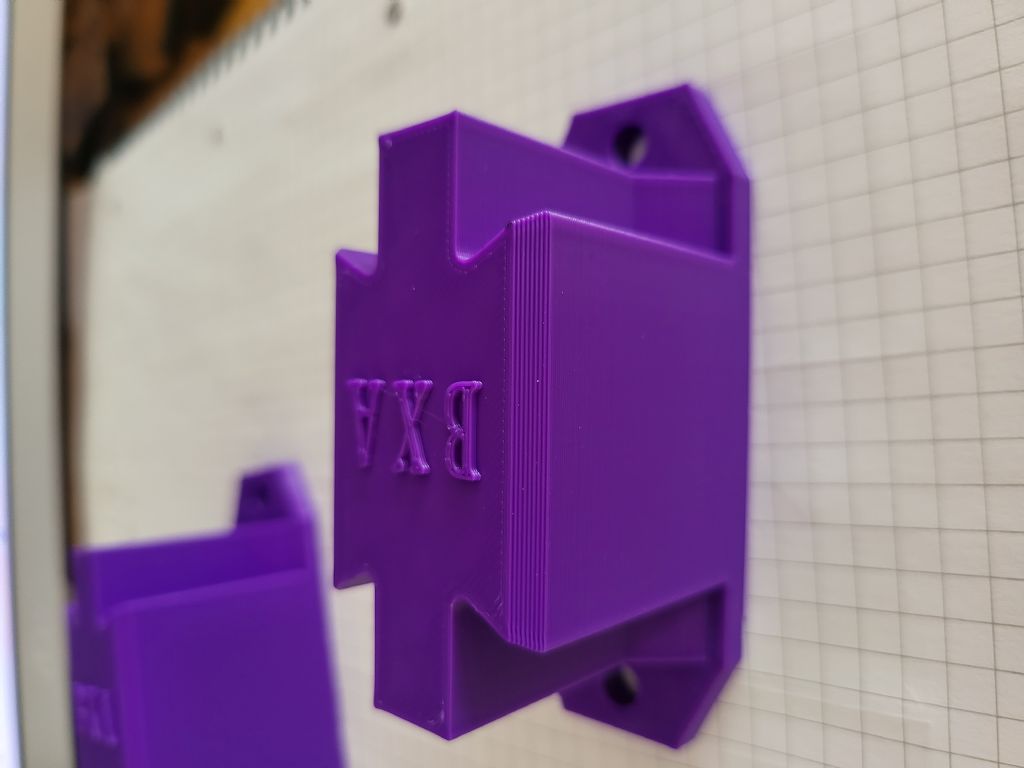

Here the few things I printed up to now, without changing anything except sending the stl through the Creality slicer.

Ah, a well known problem from the old forum: VERY difficult to add text after a picture, if one doesn’t add a placeholder before.

Anyway, The picture shows the usual Benchy, a test pyramid, a test cube and a ball joint. I neve saw such a flat and fine underside of the prints as here on the ball joint.

Now the less agreable points. The operating panel is very primitive and lacks some important things. E.g. it is not possible to adjust the printing speed, it the temperatures from that panel. It is said that the printer internally works with something called Klipper, but Creality cut off all what Klipper could do.

I just hope there will be some updates soon. In YT there is a description how to ‘free’ that Klipper thing, but it’s a bit above my head.

About Cura and other slicers: I was using (up to now) the Prusa slicer, but I downloaded also the newest Cura version. Cura has profiles for almost any printer on the market, but NOT for the K1. If it is easy to set up a profile I don’t know. Seeing what the printer does before the print really starts, I think that would be hard.

Ok, let’s see how my first entry in this new forum works. A spell checker was not active, so I hope I found all my errors.

Kind regards,

Hans

John Hinkley.

John Hinkley.