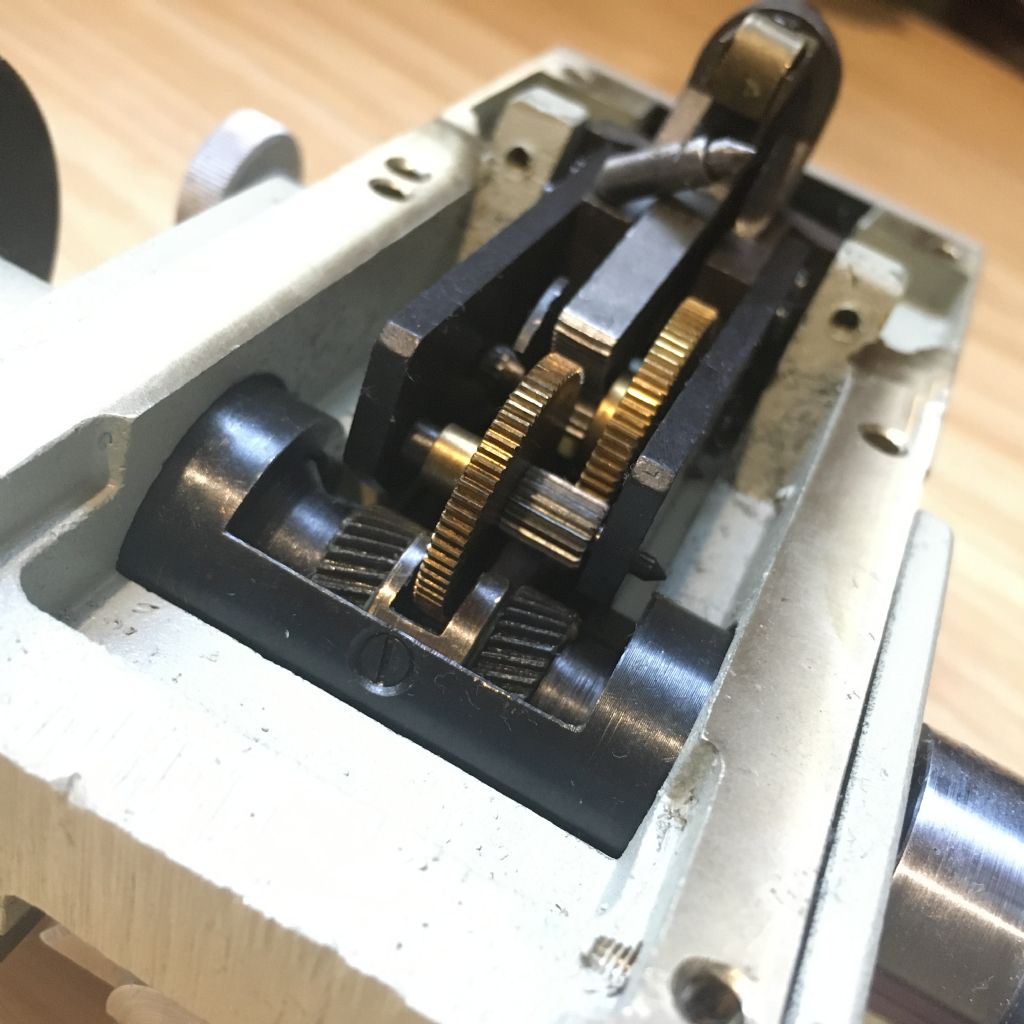

Now that I understand the limits of this machine in respect of gears, thanks everyone, I'm experimenting with moulds. It's apparent that the software is as important as the printer, and I'd be grateful for suggestions!

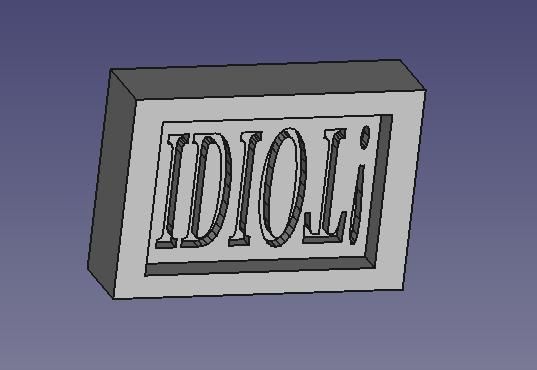

My daughter, who manages a team of young people and the quality of their written work, asked if I could use my new toy to make her a rubber stamp containing the word 'IDIOT!' Being a Linux Fanboy, the following is based on Open Source software.

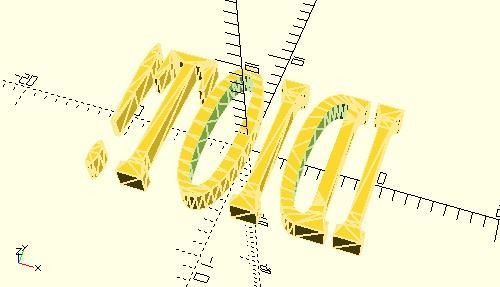

I used Inkscape to draw and invert the text. Inkscape is a 2D Vector Graphics editor, ie drawn objects are represented mathematically, not constrained to any particular size or media. Everything is editable and scaleable without loss of resolution. It can rotate, invert, and perform many other graphical manipulations. Excellent for developing 2D layouts thus:

So far so good, but rubber stamps are 3D objects. I used an extension called 'Path to OpenScad' to generate a 3D STL file. The extension traces the paths representing the text and boundary box and extrudes them by a standard amount. The result is a 3D mesh, displayed in OpenSCAD:

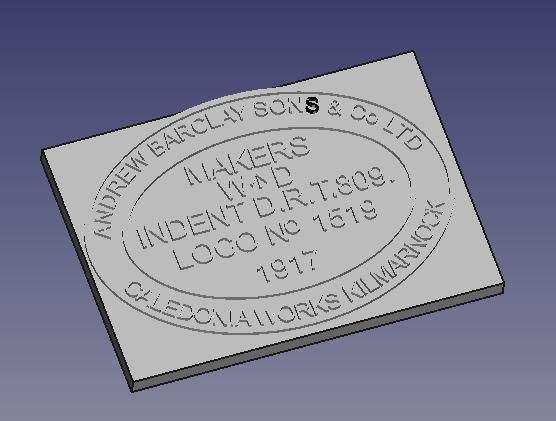

OpenSCAD is just used to save the file in a format FreeCAD can read (*.csg). FreeCAD is used to add the moulds base and sides to the letters:

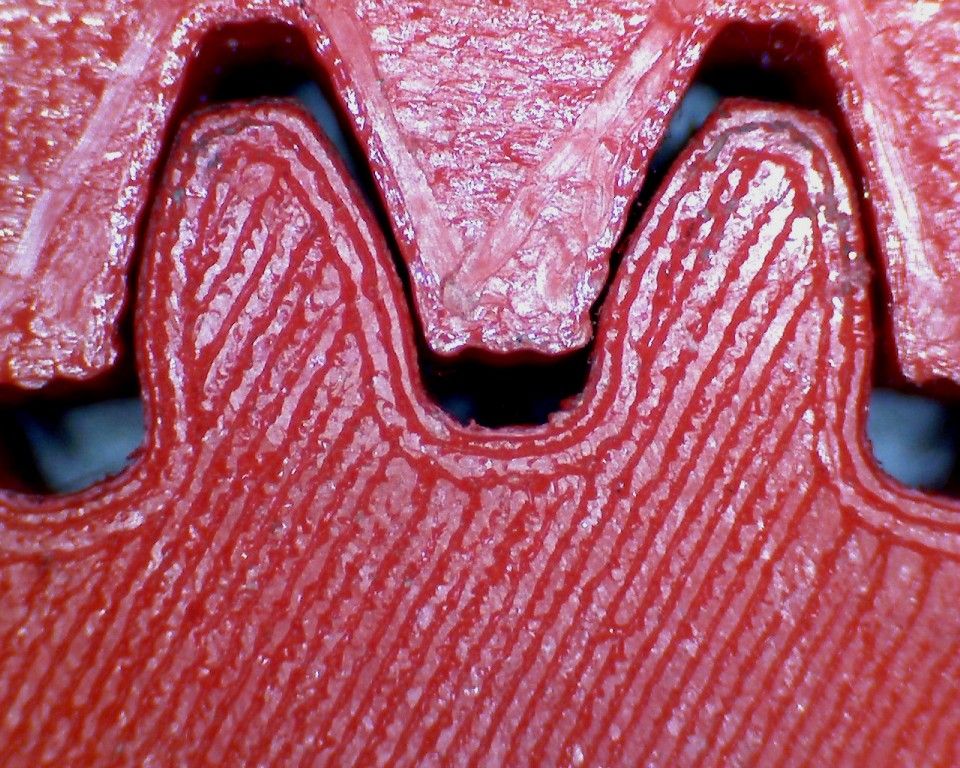

FreeCAD can output the mould object as an STL file, for slicing and printing, oh dear!

The whole job had to be done twice because the first print came out far too small. (The lower idiot.) Turned out to be a limitation of the extension 'Path to OpenSCAD', which – unlike Inkscape – assumes pixels (dots per inch). As my Inkscape master was defined in millimetres, the result is 25.4/90 too small. There are quite a lot of other tripwire details to get right using this software combination, and I may be overcomplicating the process due to ignorance. Is there is an easier way?

However, it worked. The top idiot is good enough for this idiot and his daughter! Next post describes a more complex mould using the same method, which – so far – is a failure, cause obscure.

Dave

not done it yet.