Posted by Andrew Johnston on 31/12/2019 11:25:41:

Posted by Michael Gilligan on 31/12/2019 06:55:03:

….

…

SoD: That looks a rather weird gear tooth shape? It almost looks like two straight lines joined by an arc. I'd expect the involute function to be a smooth curve. Once I've sobered up in the New Year (!) I'll have a go at printing some more (smaller) gears and also thin wall features.

Andrew

Yes, another interesting diversion into how accurately does FreeCAD render an involute curve?

To print the replica Meccano, I generated the gear with Part Design's built-in Gear button in default high resolution.

Images following are all of 15 toothed Module 1.0 gears.

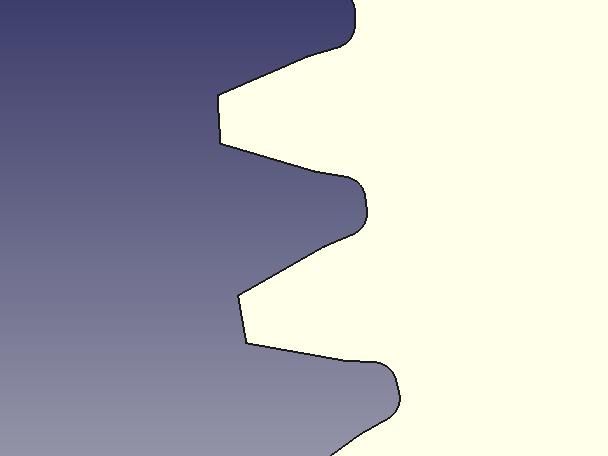

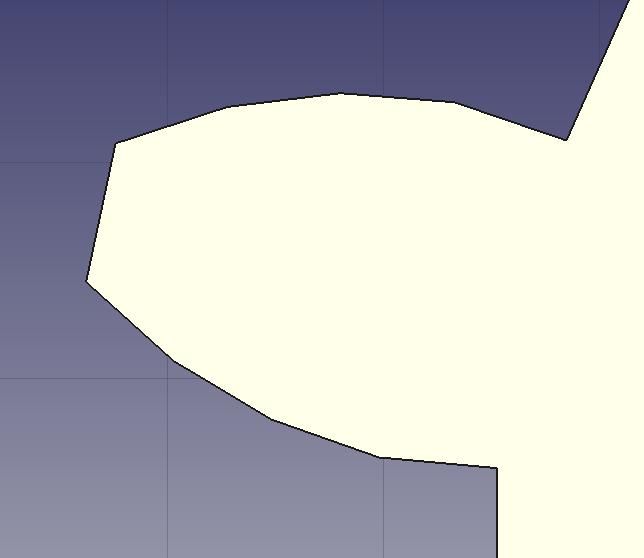

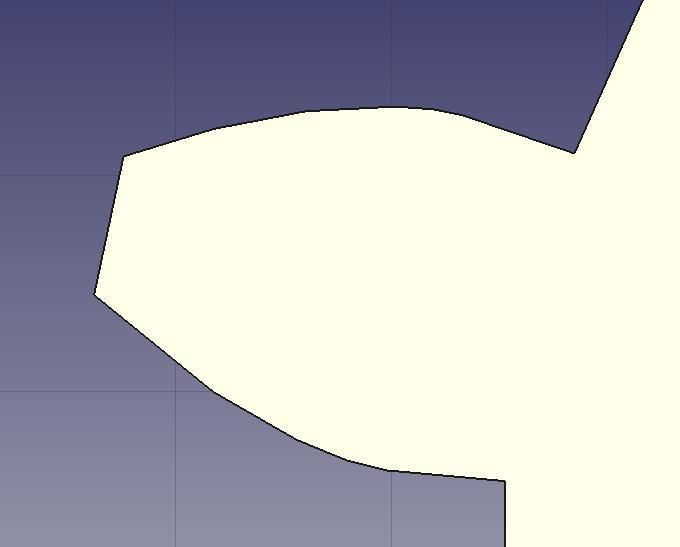

No 1: Standard Gear button in High-resoultion mode. (Not very!)

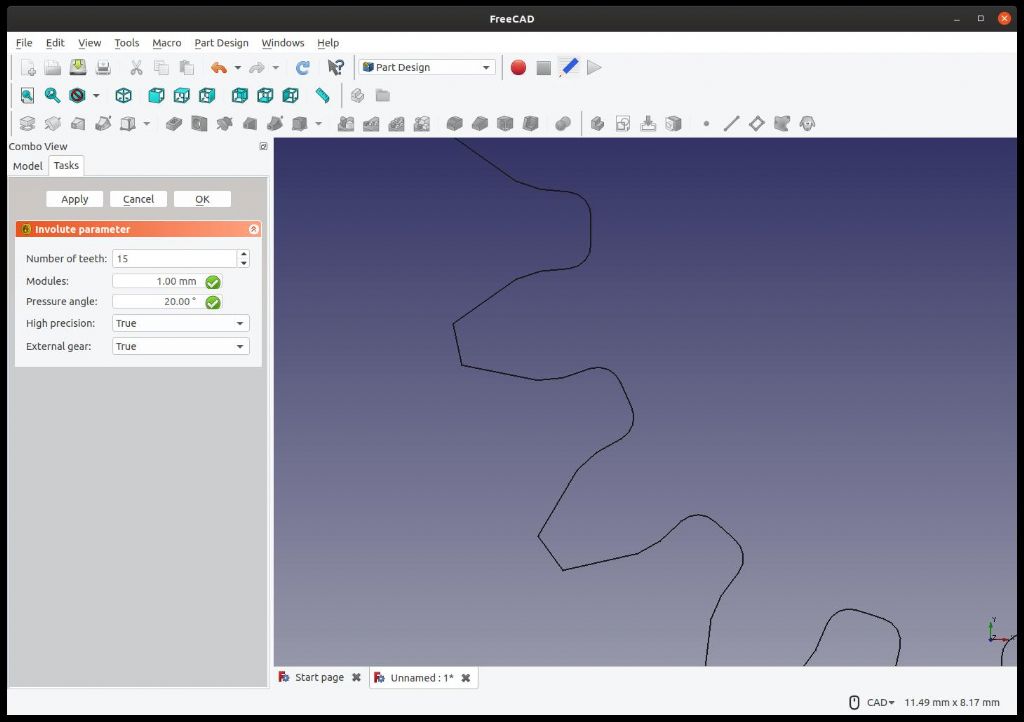

No 2. FreeCAD's Gear Workbench (an Add-on download), with the involute approximated by 2 points, very crude:

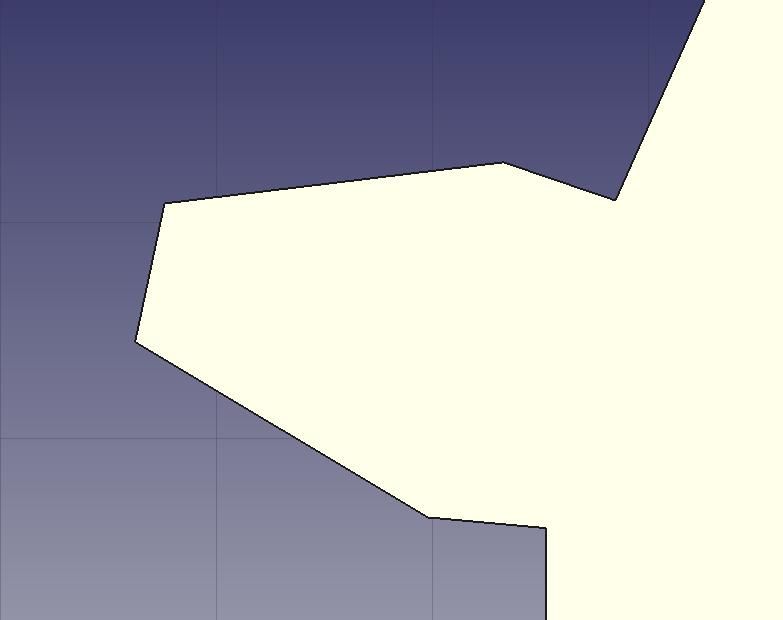

No 3. FreeCAD's Gear Workbench, with the involute approximated by 3 points, better:

No 4. FreeCAD's Gear Workbench, with the involute approximated by 6 points, good:

Of course, these are all approximations and I've not been able to find a true involute curve to compare them with. Yet another challenge: how would one draw an accurate involute? My head hurts!!!

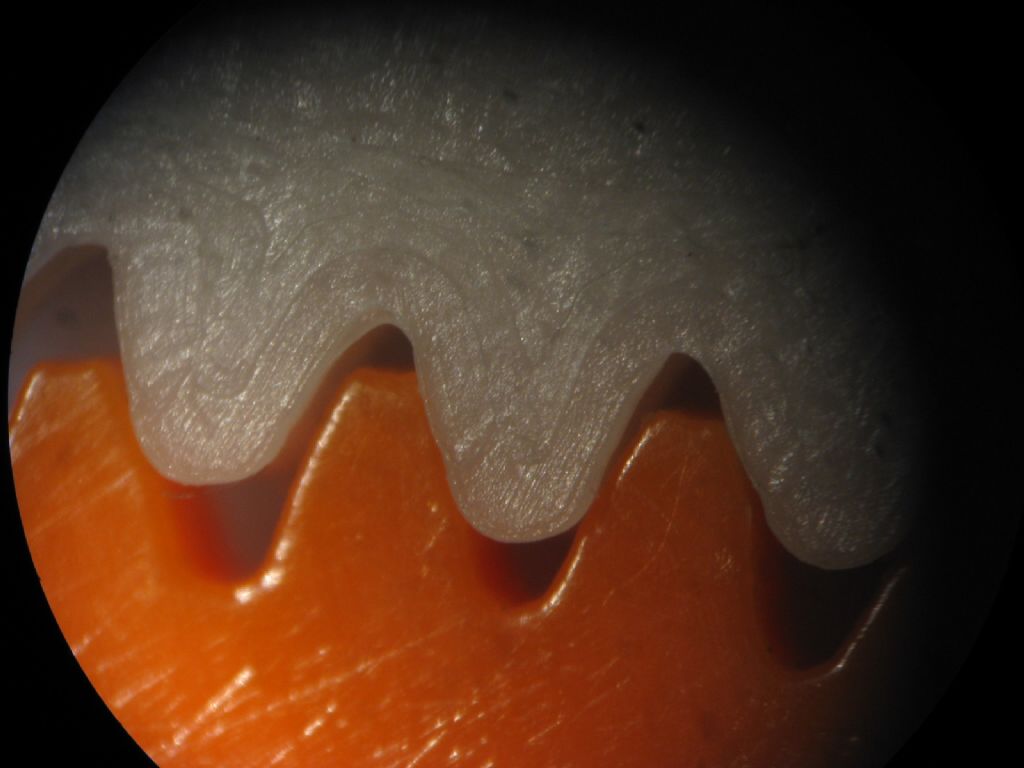

Although I don't expect to draw accurate gears on a basic 3D printer, the point at which it fails is of interest. I think it would certainly produce an acceptable profile as Engine Builder describes for a Myford-sized 63 toothed gear because, shades of Nyquist & Shannon, the errors are low compared with the size of the gear. Not so with Meccano, because the errors are large compared with the size of the teeth.

In order of increasing pain, with the last two causing most problems, I suggest the errors are due to:

- How approximate the CAD package's involute curve is.

- Vibration, stepper motor resolution, backlash, belt-drive indexing and the motors losing a few micro-steps. (Presumably a better printer would be fitted with servos.)

- The melt and smear characteristics of the plastic.

- The size of the nozzle and feed errors (too much or too little plastic)

Talk of sobering up reminds me there's Prosecco in the fridge. Mustn't let it go off!

Dave

not done it yet.