> This thread is really revealing about the current direction of MEW. Motorcycle articles are, apparently, "de rigueur" but it takes a forum poll to justify one on a tailstock rack-feed

Some of my comments were a little tongue-in cheek

I do think the 'bar' for reprinting an article has to be a lot higher than for new material, unless it is a very short (like filling a gap with a chuck cartoon). My job would be very easy if all I did was reprint the best tooling articles from 116 years of ME!"

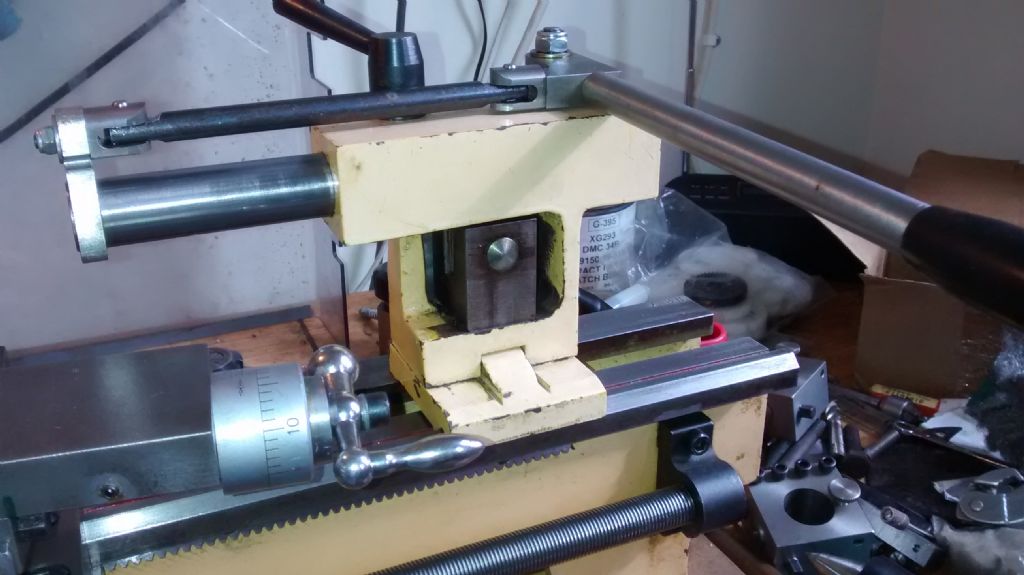

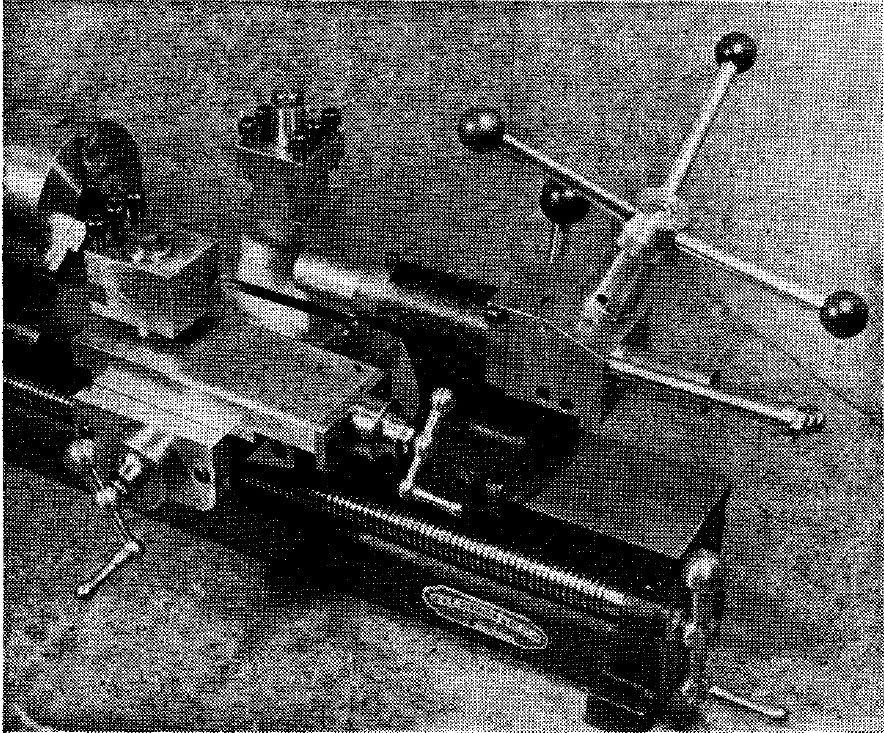

There are also issues of quality of images; drawings can be redone, but the pictures from old MEs are not printed exceptionally well and don't scan to anything like the standard I would like to use.

So I need to be really sure it's wanted. Of course the ideal solution would be someone making an updated version and writing it up with new pictures (ideally in similar concise language to Ian Bradley!)

An alternative is to put the Ian Bradley articles on line, of course.

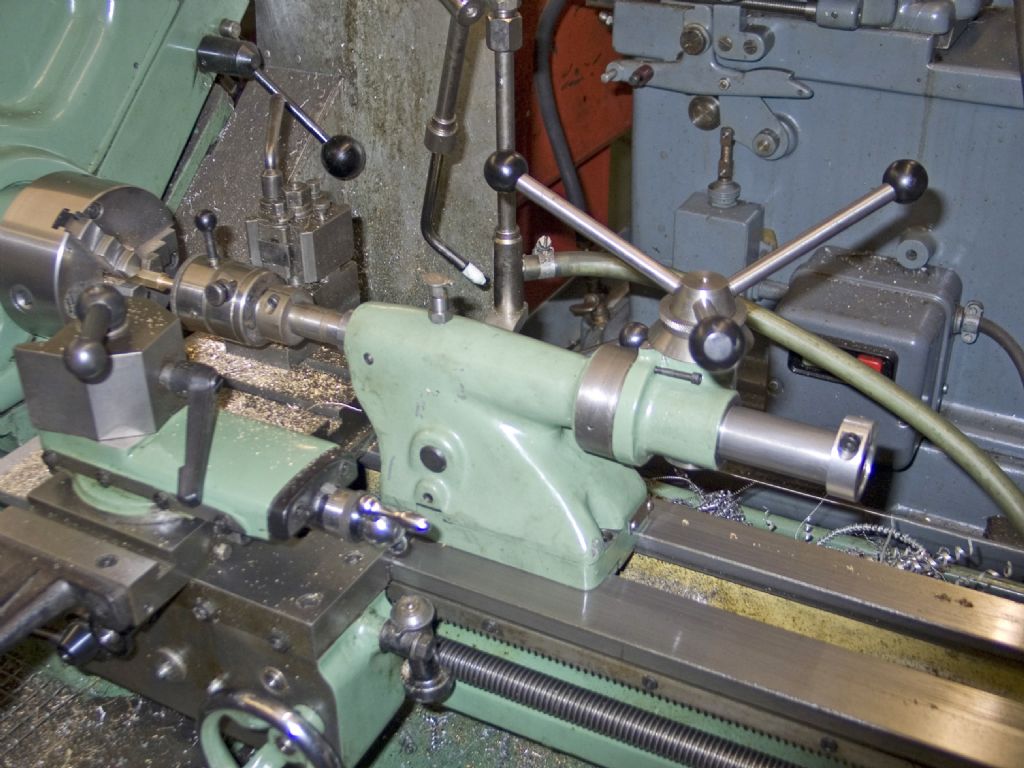

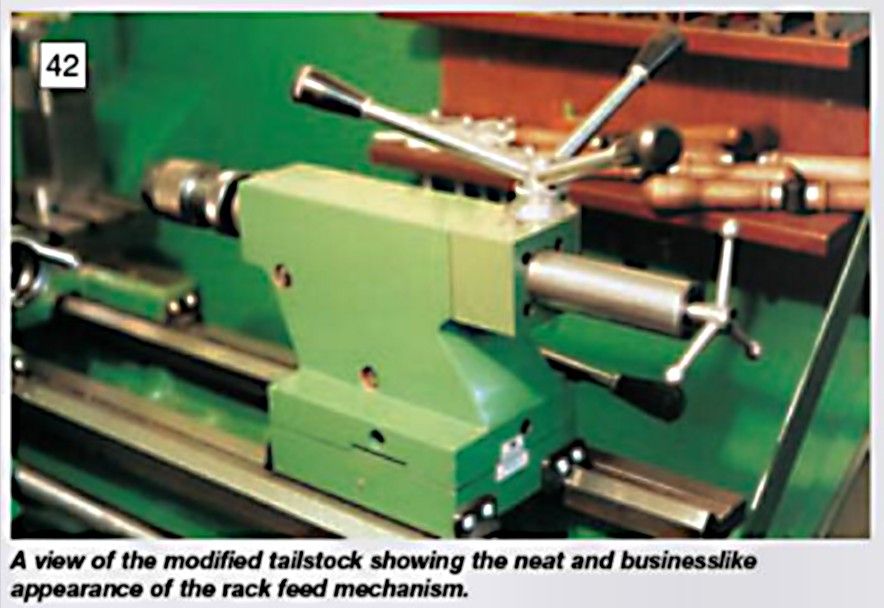

I recall the Warco BH600 article, but it wasn't in MEW, it was have been in Anthony Mount's series in ME with the tailstock starting in issue 4207. It looks a much neater design but is a bit recent for a re-run in MEW.

There's also an excellent article for the Unimat (which could be scaled up) in issue 178 of MEW by Mr Rhodes.

Neil

geoff walker 1.

I blame it on the medication.

I blame it on the medication.