CovMac Screw-Cutting Gearbox – I have decided to remove the screw-cutting box, early, for three reasons:

1) To give me a winter project, and for the gearbox to act as a pilot for the whole job of restoration.

2) Cautions were expressed about lifting and transit, as to protecting lead-screw and power feed bar, and we thought it better to attempt their removal. (Wisdom from Phil Whitley and Brian Wood).

3) A very generous offer of help on the day from Martin Whittle, who only lives 8 miles or so from Totton, where the bulk of the lathe still lives.

This third was very fortuitous, for I would not have managed gearbox removal alone – Martin was the star of the day, and he even managed to christen his 3/4 inch socket set. I learned so much from him, hands-on, to add to the distance learning I have received from other members of this forum. We safely removed screw-cutting box, lead-screw and power bar.

The gearbox is relatively simple – an input shaft, tumbler gear shaft, with seven tumbler wheels, and an output shaft with an A & B speed setting. Altogether it gives 14 changes of thread pitch without change wheels. Although this was relatively restricted, even by standards of the 1940s, particularly American lathes, a full set of change wheels boosted this to 42, in imperial, and another set was offered to make a metric transition. As a museum project, I might aim to restore all change-wheels, in time – when I own a milling machine – medium term future. Gears are slected using chunky cylindrical knobs, with powerful springs within, and a pin is retracted and replaced into the casing on each change. They have a positive feel to the. The A B lever was jammed when I got the lathe, but freed off reasonably easily, using emery cloth to grip, and water-pump pliers.

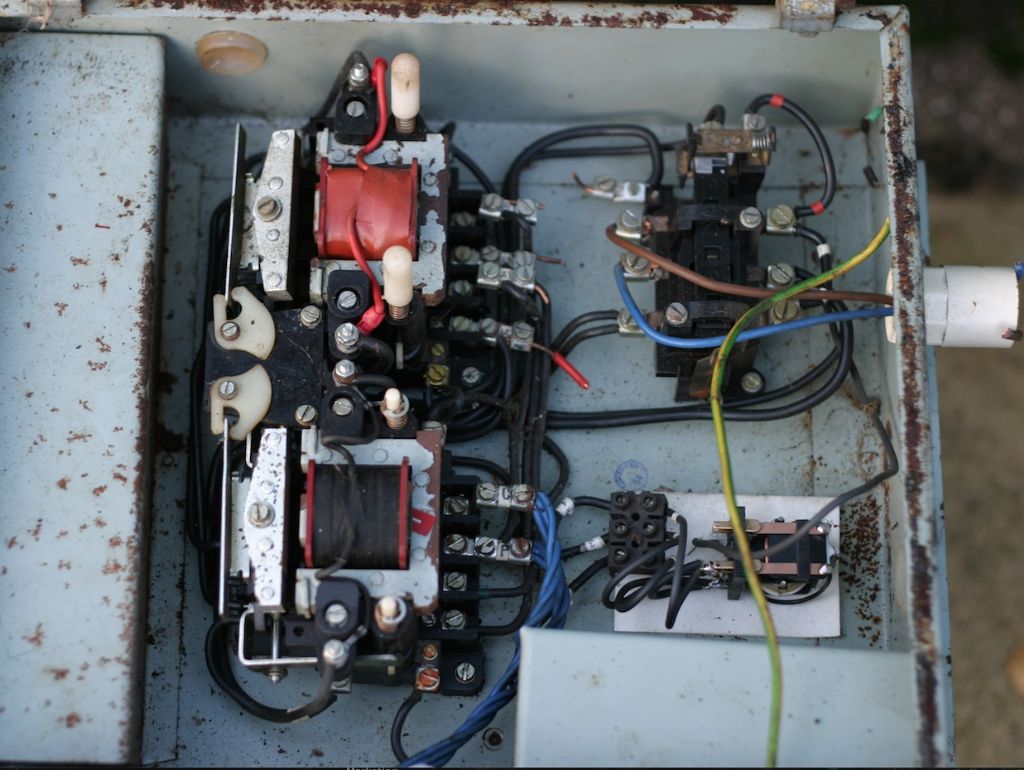

Here are four pics of the box – three with it still pretty filthy, inside and out, and a bit cleaner. So far, with painted areas, I am having great success with an initial bath of Nitromors, washed with detergent and hot water, and dried off, then a spray application of Mr. Muscle oven cleaner, again washed and heat dried. The two work very well in tandem. Of the two, the Mr. Muscle is by far the more toxic, and really must not be breathed in. It is not nice. The CovMac, being wartime produced, never had any strong enamel paint, and its two coats of paint (originally a dark grey, over-painted later in a lighter battleship grey) are pretty crumbly, not difficult to see off. Internals, I have bathed with a mix of 95% white spirit, 5% engine oil. That seems to work well enough, and is relatively cheap.

The brass label has full spindle speed, screw-cutting and sliding and facing values. The gearbox is of total loss design, yet with a sump plate and drain bolt. The box has a copious number of little oiler cups, some missing their top caps, which have a patent number on them. Luckily, we can still buy these little oilers, new. I need a good number, as they appear all over the CovMac.

Once clean, it was immediately apparent that there is serious damage to a number of tumbler wheel teeth, and we need a rebuild. At least five out of seven wheels have serious chips, and their gears mesh in pretty bad tempered, graunchy fashion. An engineer as educated and experienced as Brian Wood has no real idea of what might have caused such damage – apart, perhaps, from one of the Union chucks, into which somebody once drove a cutting tool, and tore away 25% of the inner face. It would be interesting if anybody can come up with any other answer. All suggestions will be entertained. I found nothing in the box to prove cause of such damage, just a medium level of swarf.  The other five wheels in the box, are in reasonable, general shape. The only other item of note, on first appraisal, was an amount of lateral slop in the output shaft, but its teeth are the best in the box. The blue marks on teeth in the cleaned-up picture are my black felt tipped pen, where I was trying to do a wheel count. It is not easy to count them in situ. All I am sure of, until the full strip-down is completed, is that the biggest tumbler wheel has 44 teeth. I am [pleasantly surprised by the simplicity of this gearbox- this is fortuitous, since, being a beginner, simple is all I need at this stage of my learning curve – it is steep, but, with a bit of help, I am enjoying every minute of it.

The other five wheels in the box, are in reasonable, general shape. The only other item of note, on first appraisal, was an amount of lateral slop in the output shaft, but its teeth are the best in the box. The blue marks on teeth in the cleaned-up picture are my black felt tipped pen, where I was trying to do a wheel count. It is not easy to count them in situ. All I am sure of, until the full strip-down is completed, is that the biggest tumbler wheel has 44 teeth. I am [pleasantly surprised by the simplicity of this gearbox- this is fortuitous, since, being a beginner, simple is all I need at this stage of my learning curve – it is steep, but, with a bit of help, I am enjoying every minute of it.

Doug Goding.

Actually it is missing and there was a worrying amount of swarf in there when I got it!

Actually it is missing and there was a worrying amount of swarf in there when I got it!