COVMAC UPDATE

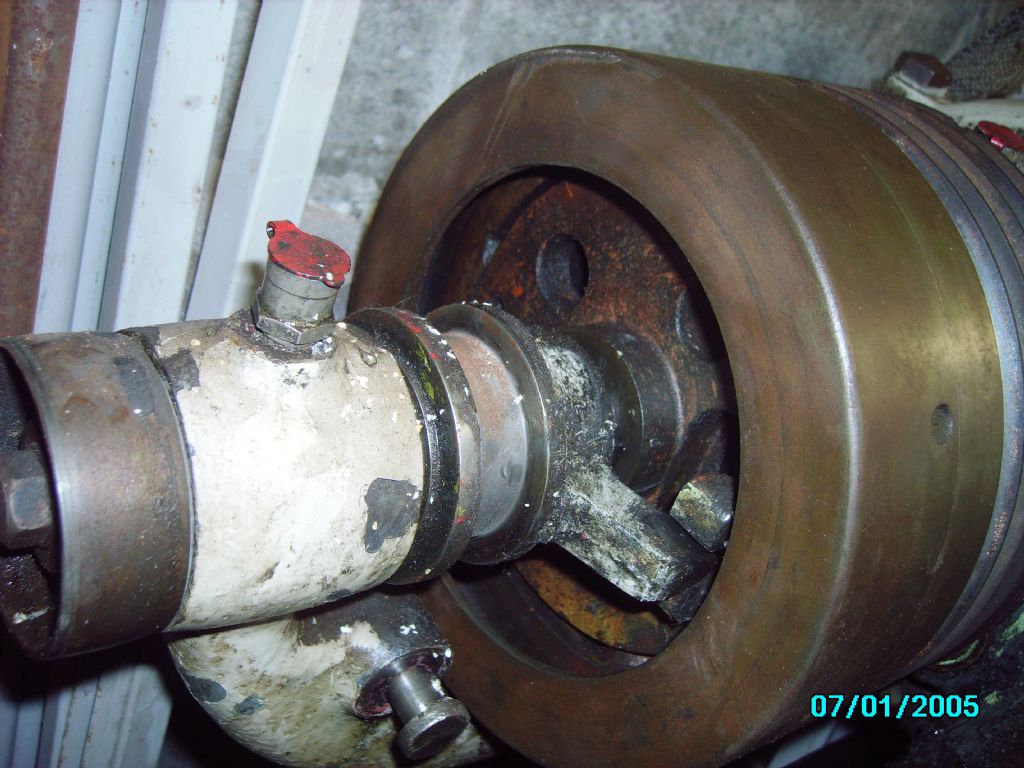

Finally, some real progress on moving my CovMac from Southampton – the job was badly delayed by tailstock legs being deeply concreted into the floor – shown above. Basically, the previous owner had compensated for a fall in levels in his shed by placing its tailstock legs into a broad, shuttered bath of raised concrete. And it was a very solid and heavy mix of concrete.

I scratched my head, and pondered my own innermost futility, on two visits, messed about with hammers and chisels, and hardly dented the problem.

This was not successfully approached until I had full faith in my engine crane of 2 tons capacity.

Trying to free the legs, with weight of lathe bed still on them was just impossible. Access was very limited, and the drip tray was much in the way. It was not until I had removed the headstock, and came to shackle the crane up for a test lift of the main bed, and I had not to lift the bed by much, to have the sheer weight of tailstock legs actually free themselves from the ground – (I think they weigh over 100 lbs – I could only just carry them to my car). I tumbled them out backwards.

This was a great leap forward. I enclose shots of the culprit. Once out of the ground, the concrete was simply knocked off with a lump hammer. It was such a huge problem in situ. It was very easy once out of the ground.

The big move is due next week. I will post many more pictures, when I have them downloaded from my camera phone.

I now have five pieces – headstock, headstock plinth, main bed and drip tray to move.

Lifting the main bed off its legs and down to ground level was, as Phil Whitley predicted, a little bit "hairy" but I managed it okay. It was very headstock end heavy, for I had accidentally jammed carriage & apron near the headstock end, and the tailstock rose three feet in the air above it.

The crane was magnificent, and the lift was very stable, aside of the bed, when being lowered, wanting to roll forward onto the apron and screw-cutting gearbox. I managed this using a bar through the eyehole under the headstock, and chocking with wood.

I used twin slings, each of 2 tons rating, through a piece of straight bar in the jib of the crane.

It is a real relief, for a novice, to have it all at ground level. Suffice to say, I have never lifted something this heavy before.

I have broken nothing on the lathe, and have not hurt myself, either.

Am presently finishing building the necessary pallets to get the big beast out to the road.

All in all, I think the weight estimated for this lathe, on Lathes.co.uk @ under a ton, is a significant under-estimate.

Tailstock, headstock, tailstock legs, headstock plinth, motor plate and motor are all really massively heavy items. I am beginning to understand Neil Wyatt's use for it of the word "behemoth".

I think, altogether, that this lathe actually weighs about 1.4 tons.

All input, help and encouragement from you engineers has been worth its weight in gold. I really have appreciated being welcomed into this forum. Many thanks.

Chris.

Edited By CHRISTOPHER MILLS 1 on 12/11/2014 10:39:36

Doug Goding.