CovMac Lathes

CovMac Lathes

Home › Forums › Beginners questions › CovMac Lathes

- This topic has 432 replies, 37 voices, and was last updated 13 December 2021 at 20:27 by

Doug Goding.

-

AuthorPosts

-

11 September 2014 at 22:22 #163397

Phil Whitley

Participant@philwhitley94135That sounds interesting! I have never done that before. I will look for Johns post!

Phil

11 September 2014 at 23:28 #163403CHRISTOPHER MILLS 1

Participant@christophermills1Phil,

Many thanks for your time in offering all of this advice. I will take it all onboard, but the friend who said "pallet it" is a very experienced engineer, who has a great deal of experience moving machinery. He has many lathes. Maybe he has not moved many??

I would build a "Rolls Royce of a pallet, because it is not going on any standard sized pallet, being over 7 feet long.

I will look up all the references you have kindly given me.

If I have to move it myself, my inclination is to separate the bed from the legs, and move them separately.

Is there any sense in that? It would address its top-heaviness. I wish to dismantle it anyway, for renovation.

I will take no chances, because I really love this lathe, and I am under no real time pressure, because the vendor is very relaxed; it was his father's and he has taken over two years even to advertise it for sale. He is very happy to see it going to a good home, for the alternative was the scrapman, as nobody else was interested in it.

I cannot afford a professional company, so I really have to shift it myself.

I have to swivel it through 90 degrees, twice, to exit the shed it is sat in.

So, I was thinking of running two heavy duty plywood plates, under the headstock and tailstock ends, with twelve swivel castors, altogether rated at 2.4 tons, and run it over two 1/4 inch plywood sheets, on the floor, to smooth out any bumps in the concrete.

That would move it to the road. I would use bottle jacks to get it up, with two 9 x 2 timbers, under the bed, high enough to push the plates with castors in under.

There is a 2 ton capacity engine crane, hand operated, on eBay for £133. It looks a serious piece of kit.

Could I use one of those to put it onto a flatbed?

I feel happier with the idea of separating bed from the plinth and legs.

I paid £400 for the lathe, and am budgeting about £400 to move it.

Your advice is very much appreciated.

Many thanks.

Chris.

12 September 2014 at 03:15 #163410Muzzer

Participant@muzzerBe wary of the so-called "2 tonne" engine cranes. If you mean one of these fine machines, which are available in almost any colour and brand name under the sun, you can start by halving or thirding that number. I enjoyed great amusement when lifting my Bridgeport clone milling machine (almost exactly 1 tonne) with one of these. With that kind of load, it wobbled around as if it was made of rubber. Luckily I have a proper, sturdy engine crane that was able to pile in and finish the job without me ending up in a box and the machine in a hole in the ground.

I'd love to see somebody lift 2 tonnes with one of these.

Merry

Edited By Muzzer on 12/09/2014 03:16:19

12 September 2014 at 08:04 #163418CHRISTOPHER MILLS 1

Participant@christophermills1Muzzer,

Many thanks for this – I thought these looked too good to be true, for the price.

How do they get away with this, under our famous Health & Safety culture?

Chris.

12 September 2014 at 09:14 #163424Phil Whitley

Participant@philwhitley94135Hi Chris, I am very reassured! making your own pallet is a whole different ball game. taking the lathe off its legs does make the whole job MUCH safer It sounds like it is going to be ok. I can't comment on taking the legs off because I have never done it on mine, there will be huge whitworth bolts somewhere underneath. If you can get forks under the bed, or use a lifting hook and get the whole plot just clear of the deck, then unbolt the legs, which probably means the drip tray and its sump comes off as well, then lower it onto a pallet, job done! As I said on another forum, I have seen grown men cry when their pride and joy lies smashed on the floor! Only a couple of weeks ago I was watching a guy move an immaculate looking BIG Colchester with a fork lift, and if it had not been for a ratchet strap which suddenly twanged tight, it would have been on the floor! Good luck! Can' wait for some pics, I will try to get some better ones of mine next week, unfortunately, today I will be mainly plumbing (another job)

Nervous Phil.

12 September 2014 at 09:36 #163427CHRISTOPHER MILLS 1

Participant@christophermills1Phil,

Although new to metal lathes, I have very carefully spent 18 months studying every aspect of interest to me.

After talking to you, and others on this forum, I am now quite looking forward to moving it.

I think I am resolved now to separate bed from base. Cast iron plinth and legs look so fragile, and the top heaviness seems an accident waiting to happen.

Do you know if the legs come off the drip tray, and then the bed off the tray, or if the legs are integral to the drip tray?

There is a series of "You Tube" videos, headed "Hendy Lathe Move", where this enthusiastic, novice (a bit like myself) American moves a huge old Hendey lathe, in some of the most lunatic ways possible, all alone, every stage done entirely alone) into his basement, and it is more useful, in some ways, watching how "not to do it" than watching professionals doing it properly.

He survived, but he caused three major pieces of damage to the Hendey, including smashing off the taper turning attachment, bending the main rod alongside the lead screw, and smashing off one of the main casting bed legs. He was lucky he did not kill himself, at one point he has it at the tops of a flight of stairs,he is standing at the bottom gazing up at it. When it did finally fall, and smashed the bed leg, he had, give him credit, stepped to one side, out of the danger path.

I think I will separate the legs and bed, under carefully controlled conditions, then bolt and lash the bed to the Rolls Royce pallet" and have my friend put it to his transport. I will discuss it with him on Sunday, when I see him.

Can I visit you, and see your CovMac, when I am up north on business? I would much look forward to it.

Yours differs a little in that it has wheels on the side and compound slide controls. Mine has those cute little handles, with two pieces, a ball and a sort of a toggle. I do not know what they are called, but I love them.

I would guess that my Covmac is a little earlier than yours. I hope to get you pictures in the next week or so. Mine is a battleship grey colour, with a darker grey paint showing underneath. I want to restore it to the darker grey colour.

What do the two big handles on the top of the headstock do? I imagine the left hand one is setting four different spindle speeds, but the right, I do not know.

Chris.

12 September 2014 at 12:56 #163442CHRISTOPHER MILLS 1

Participant@christophermills1Phil,

Sorry to be a pest, but I am calculating the weight I have to shift.

Assuming Tony is right about the weight of the standard Covmac 13" geared head model @ 1870 lbs, 130 lbs short of the ton, our models are heavier in that they have an extra 21" of central bed, and the plinth instead of the headstock end legs.

I am trying to calculate weight of the bed and headstock on their own.

If I remove tailstock,(80lbs?) carriage (200 lbs?) , drip tray, (50lbs? plinth and leg, (80lbs) gap piece (30lbs) and chuck, my feeling is the bed and headstock, and gearbox, remaining are going to be well less than a ton, in which case I can shift it using a drop tail lift three and half ton van?

An average drop tail lift will take a ton. I had ruled that out, early, but now dismantling I think will enable it.

This seems to be my answer, assuming I can separate bed from legs okay .

Are you in broad agreement with me, here? I think I am getting there, now.

Many thanks.

Chris.

12 September 2014 at 21:41 #163487Phil Whitley

Participant@philwhitley94135Hi Chris,

You are not a pest!!! this is exactly what these forums are for! I will read your posts as I write and try to answer all your questions. I will also nip to my workshop tomorrow, take some more pics, including some of the leg fixings, and have a good poke about to see what is what.

I watched the Hendey lathe move for as long as I could bear it, I would give whatever is left of my eye teeth for a taper turning attachment, and he didn't even have the nouse to take it off! First things to remove are all the sticky out bits, and as a bit of general advice, wherever possible, put the bolts back in the holes, it makes reassembly much easier, you can't loose them, and you don't reassemble with the right threads, but the wrong length, and have to swap them about. The one exception to this would be the ones that hold the legs on, in order to keep the underside of the lathe smooth for sliding/rolling.

As I said before, I think taking the legs off is a good idea. The tail stock end one is a bit flimsy, and it did spring a bit on mine when I was moving it on rollers, which you cannot put under the tail stock end of course.

The problem with removing the saddle (carriage) is that you have to remove the lead screw and the feed drive rod, which means disconnecting them from the feed/screw cutting gearbox Other than this the saddle and apron removal is straightforward enough, if you are going this far, you might consider removing the headstock from the bed as well.. This would mean resetting it square to the bed on reassembly, but you will have to check, and possibly adjust it anyway. I will have a look at the possibility tomorrow to see if it is feasible.

You are very welcome to come and see my lathe anytime you are in the north, as I am what I laughably call self employed, my timetable is very flexible. If you PM me or send your email to phildothermeticatlangtoftdotnet I will give you my contact details.

I am in agreement with you, but when you remove the lead screw/feed shaft and the saddle, you will be left with something that is very heavy at one end, and no way of balancing it

The colours on Tonys site look black, but they could be dark grey, a very popular colour for this era of machines.

As far as I know the two big handles on the top are both gear levers, they may be a high/low lever and a speed change, or two speed change levers used in combination, I will find out tomorrow for you.

Tail lifts are ok but tend to tilt away from the back of the truck when heavily loaded, I can remember moving a clicking press and unloading it with a tail lift, if it hadn't been for the fearsome slope on my yard it would have been another disaster.

3 1/2 ton van? I am going to be awkward again

A 3 1/2 ton Gross vehicle weight van (GVW) means that the total weight of van and load must not exceed 3.5 ton, you must make sure that the van is capable of carrying the weight and still being legal AND driveable. Case in Point…………. I went to a local gravel quarry in my late lamented LWB Nissan Cabstar Which was rated to carry 1 ton. The guy at the weighbridge weighed the empty vehicle, then proceeded to drop a huge loading shovel full of sand on the back. He wighed it again, which showed the load on the van was 1 ton 4cwt. The cab was looking at the stars, and the steering was so light I crawled home at 30mph. I also brought my Colchester Student and all the accesories back from an auction in Hull with the Cabstar, one of the scariest drives of my life. According to tonys site the Colchester weight is just over .6 of a ton but with all the stuff I got with it, it felt more like a ton!! I transported all the bits I took of mine in a transit, on a seperate trip, and left the lathe and the motor to landylift. I will let you know more when I have had a good look at mine tomorrow.

A 3 1/2 ton Gross vehicle weight van (GVW) means that the total weight of van and load must not exceed 3.5 ton, you must make sure that the van is capable of carrying the weight and still being legal AND driveable. Case in Point…………. I went to a local gravel quarry in my late lamented LWB Nissan Cabstar Which was rated to carry 1 ton. The guy at the weighbridge weighed the empty vehicle, then proceeded to drop a huge loading shovel full of sand on the back. He wighed it again, which showed the load on the van was 1 ton 4cwt. The cab was looking at the stars, and the steering was so light I crawled home at 30mph. I also brought my Colchester Student and all the accesories back from an auction in Hull with the Cabstar, one of the scariest drives of my life. According to tonys site the Colchester weight is just over .6 of a ton but with all the stuff I got with it, it felt more like a ton!! I transported all the bits I took of mine in a transit, on a seperate trip, and left the lathe and the motor to landylift. I will let you know more when I have had a good look at mine tomorrow.Phil,

12 September 2014 at 21:52 #163489Phil Whitley

Participant@philwhitley9413513 September 2014 at 07:20 #163497CHRISTOPHER MILLS 1

Participant@christophermills1Phil,

Many thanks, and I will take your wise point on the 3.5 ton van.

I rather look forward to your investigation into my best options with the CovMac.

I see from the historical archive, that by 1938, CovMac were a subsidiary of Alfred Herbert and Company, also of Coventry.

Chris.

13 September 2014 at 16:57 #163519Phil Whitley

Participant@philwhitley94135 Hi Chris, Cut a long story short I think the Covmac is emminently stripable! here are two pics showing inside the column and the legs

Hi Chris, Cut a long story short I think the Covmac is emminently stripable! here are two pics showing inside the column and the legs

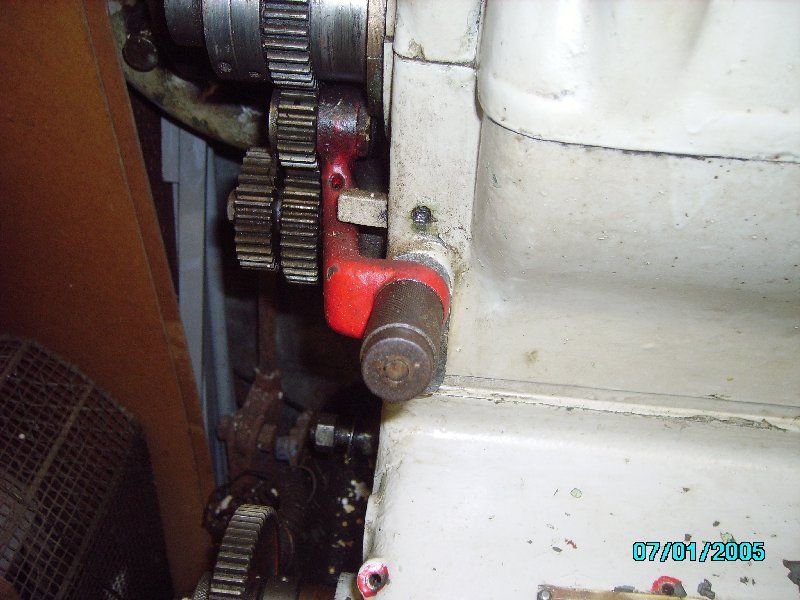

The red one is the headstock column, there are two studs and nuts but you will note 4 holes, the other two have not been drilled or tapped It is the same at the other end, (bit of a bad pic) but you can see two studs and nuts again, and two apparently unused holes.

If you remove all the belt covers and gear covers, motor, motor plate, then the banjo with the gears on it, you will see these two bolt heads

If you remove these two, and these two under the spindle

Then fit a chuck or faceplate and place a sling round and behind the chuck, and round and behind the vee belt pulley, and as far as I can see, the gearbox lifts off. You will need to make careful note of the number and position of any shims that may be in there (there may be none) If you then remove the nuts from the studs holding the legs on and remove the studs (they will probably come out with the nuts) you could lift the bed assembly with a fork truck, remove the legs, and lower the bed to the floor. As I said before if you remove the saddle you will first have to remove the lead screw and the feed shaft And without knowing how they disconnect from the feed/screwcutting gearbox, this process could be simple, or complex, I simply don't know! If you do remove them, you could then remove the saddle and apron, and the feed/screwcutting box as well, leaving you with some still very heavy, but much more manageable pieces to transport.

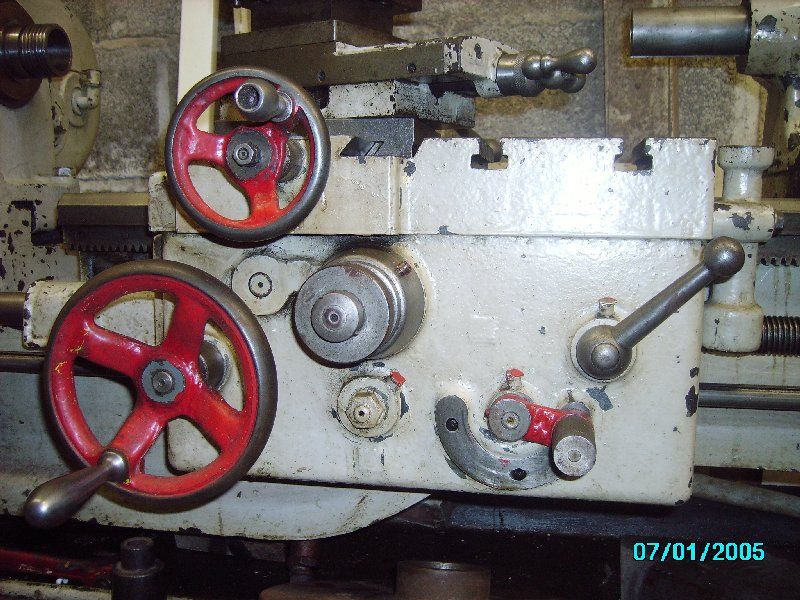

The top two levers, left hand one is the four speedchange lever, right hand is the back gear, or high/ low change giving eight speeds, four in low/backgear, and four in high. Sounds complex, but it isnt.

Tumbler reverse lever, this reverses the direction of the feed/screwcutting gearbox, and thus reverses the direction of the leadscrew for cutting left hand threads, and any other process needing the opposite rotation.At least, that is my take on this lever, some also have a neutral position so you can operate the lathe without the external gear train and the feed box turning, which make for a MUCH quieter lathe!!

saddle/apron controls, from the top. Small "ball" handle operates the top slide (AKA compound slide, which can be adjusted around an engraved protractor scale to turn tapers and for screwcutting. Small red handwheel operates the cross slide, which moves the compound slide and the toolpost across the bed. Large red handwheel moves the whole saddle along the bed. Round knurled knob in the centre of the apron switches the feeds between "sliding" (up and down the length of the bed) and "surfacing" which powers the cross slide backwards and forwards across the bed. Below that is an oil nipple (not grease!) The little red three position lever to the right selects the feed direction with a central neutral position, and the ball handle just above that opens and closes the half nuts for screw cutting. Bolted to the end of the apron on the extreme right next to the two T slots is the leadscrew indicator, sometimes called the screwcutting dial, which reads out the position of the saddle in relation to the threads on the lead screw. Once again, sounds more complex that it is in reality. The golden rule with all levers is do not change gear with the lathe chuck revolving!

The motor plate, solid cast iron one inch thick, and I can barely lift it!

The motor, and yes, that is a 12" rule! I can just about drag it across the floor, I would guess about 2 1/2 to 3 cwt.

13 September 2014 at 17:08 #163521Phil Whitley

Participant@philwhitley94135Right, it has just lost the end of that post, as the cut command did not work so I will try to type it up again

Hope all this helps. I would strip it completely, it will make the move much simpler and safer, but you would still need help and a fork truck or engine crane, and if you are going to refurbish it, why not I would not go beyond giving the headstock and feed box a good wash out, as if you remove the spindle you will have to reset the bearings and that is a tricky job, but not impossible by any means. You will have to check the alignment when you refit the gearbox, but that should always be done after a machine is moved anyway. If I can give any more help let me know.

Phil

That wasn't as good but never mind

13 September 2014 at 17:14 #163523

13 September 2014 at 17:14 #163523Phil Whitley

Participant@philwhitley94135Hi Chris,

Where is the motor on your Covmac? I have just realised that the cast boss you can see inside the headstock plinth is where the bolt used to adjust the belt tension goes through. That is why the door is there, to get to the belt adjustment.

Phil

13 September 2014 at 17:38 #163526CHRISTOPHER MILLS 1

Participant@christophermills1Phil,

This is really wonderful stuff, and you cannot imagine how much I appreciate your going to this time and trouble. I certainly owe you a drink. It looks like you had to half dismantle your machine!!

Mine has the thick iron motor plate, like yours, but the motor on mine is much smaller. Mounted to the rear base of the headstock end, it has twin 'V' belts which run up at about 60 degrees, and attach to the back gear side of the headstock. They do not go anywhere near the headstock plinth – miss it out completely.

If I remove the carriage, can I not roll it to the end, and off the bed, supporting lead screw and rod, and then re-bolt the two back into their tailstock housings, leaving gearbox end untouched?

The dark grey paint revealed on yours, under the white paint, exactly matches my base coat, and I think that is our original colour.

I had hoped the lathe would be easy to dissemble, being made in the 1930s/'40s.

What socket set do I need? Is it classified as 'Whitworth"?

I have tried your dot com address but it blanks me. You can trie me – cpmills1 'at' g mail dot com

Many thanks, and best wishes. Have a great weekend, Phil.

We surely now, finally, form your hoped for CovMac Owners' Club? It is fun to have a Covmac, I know that already.

Have you not run yours yet? Is it because you only have Three Phase in your workshop? I recall you said the CovMac motor was single phase.

Chris.

13 September 2014 at 18:05 #163527frank brown

Participant@frankbrown22225When I moved my Deckel clone, we used a 7 1/2 tonner, because its weight is 1000kG ~1 ton. We could not find a tail lift rated at a ton on a smaller vehicle. It was only a couple of years ago but I think that the driving license regs have changed in the intervening period so its not possible now.

Frank

13 September 2014 at 21:00 #163540Phil Whitley

Participant@philwhitley94135Hi Chris, got your emails, Your lathe seems almost identical to mine, and the conehead of flickr although that seems to have a slightly different feed box, and no plinth with cupboard. I think your motor fixing is exactly the same as mine too, If you look inside the "cupboard" there is a large nut and thread which is attached to the motor plate, and adjusts the belts. No dismantling to do, unfortunately that is how it is at the moment, but it will be soon going back together and traveling a few yards to my "new" machine shop across the other side of the main workshop

I think maybe you could remove the saddle like that, but how would you lift it clear without damage to the lead screw, it is VERY heavy. you could separate the apron from the saddle (apron is the bit that hangs down the front with the controls on it) then remove the saddle, then the apron, then replace the lead/feed end bracket. I have never done this however, so I am only assuming it is possible!

The dismantling does seem to be very straightforward, as you say, the 30's/40's construction is basic, rugged but also simple and uses a few bolts to hold the whole thing together. Now I have had a good look at mine, i realise it is actually simpler than I thought, and I could have continued stripping mine if landylifts Hiab hadn't been able to lift it.

Socket set needs to be Whitworth or BSF (mostly the same size) You will also need a few good BIG screwdrivers, one of which should have a hexagon on it so it can be turned with a spanner if neccasary. Some lever bars, and a soft (hide) faced mallet. When removing screws the screwdriver blade needs to be a tight fit in the screw, almost to the point where you need to tap it with a mallet to get it in the slot, then push HARD and turn sharply, with the spanner if possible. you should also take some release oil/WD40 although it is rare for a well oiled machine like this to have any seized bolts, a plentiful supply of rags/ handwipe paper. Clean it down before you start, it stops accidents, slips and drops.As I said before, put every bolt you can back in the thread it came out of, and with nuts and bolts on guards etc, put them back in the holes they came from and tighten, it makes reassembly so simple, and saves hours!

I haven't run mine yet, but that is simply because for the last 20 years I have been involved in other things, and My brother was using my workshop for his business http://www.cambraicovers.com/ I got it back about five years ago. On the same day Steve from landylift was moving my Covmac to my workshop, he was moving the last of my brothers heavy machinery down the road to his new workshop, it all worked very well I then embarked on a three year refurb on my workshop working on it when time allowed. If you get over to see me I can show you around! If you have three phase, you also have single phase, you just use one of the phases, and a neutral.I have tried to get a three phase 3 hp 750 rpm motor, but they are expensive (about £250 new, very rare used) and though they are more efficient than a single phase motor, I will probably use the original motor for now. Incidentaly, I see the "stayrite" starter on the wall next to the lathe, although the joke where I served my apprenticeship (I am originally an Electrical Engineer) was "Stayrite NEVER Right" I would get it, as it matches the motor. Strange motor on yours, shaped like a Brooks, but with the vents through the side of the foot is unusual, interesting!

I think I feel a very exclusive Covmac owners club coming on!

Phil

16 September 2014 at 09:28 #163683Phil Whitley

Participant@philwhitley94135Right!! I am going to ask the question here and all the other sites I frequent, Is there anyone out there who owns, or knows of the existence of a Covmac 17" Lathe as illustrated here http://www.lathes.co.uk/covmac/page2.html

We don't want to buy it, but would love some photos and history if known..

Phil

16 September 2014 at 12:53 #163692Ian S C

Participant@ianscIf you decide to take the bed off the plinth, you might just about need 3/4" drive sockets, the bolts will be tight.

Ian S C

16 September 2014 at 13:48 #163694CHRISTOPHER MILLS 1

Participant@christophermills1Ian,

Many thanks for that. I am checking out the status quo tonorrow. I do want to take it to pieces, as I have no experience moving a lathe this big, on its legs. I feel alot happier withthe bed on its own.

Phil says th eheadstock comes off easily. We are less sure about removing the carriage.

Chris.

17 September 2014 at 17:32 #163786CHRISTOPHER MILLS 1

Participant@christophermills1CovMac Lathe Move – Day One.

As a non-engineer, one who has approached this subject as an historian, wanting to save a piece of our industrial heritage, I think it may be of interest to you accomplished engineers, to see how a complete novice took in his first day as an engineer.

What a day I have had! Firstly, I have not been so filthy dirty since being a child. Crawling around under that lathe in years of accumulated dust was an experience. I will try and post pics of this CovMac soonest. It is in a dusty old environment.

My CovMac lathe is the 13" geared head, as shown on lathes.co.uk but with a 54" bed, and a headstock plinth similar to the bigger 17" geared head model.

Progress:

1) Have removed all four big Whitworth bolts holding bed to legs and tray. Three were not much more than finger tight, one was loose.

2) Have removed back gear guard, tail-stock, gap-bed and wooden pole.

3) Have dropped the banjo, taken three gear wheels out, and loosened three out of four of the headstock bolts – the 4th has a bit of face damage, which I will have to dress with a file; I could not get a socket on it. I will have no problems getting the headstock off, I feel.

Lack of progress:

1) I Cannot yet see work out how to get the tool post off, or the slides.

2) I had not noticed, on my first visit, that this lathe is actually concreted into the floor, both ends, tail stock end more so than the headstock plinth. The bottom of the tailstock legs are encased in a fillet of concrete, about 1 1/2 inches deep. This is raised off the floor, by that I mean the legs are not sunk into the main floor. There is less on the headstock plinth end, more just a skim of screed along one end.

This presents me two problems:

1) Making sure I don’t break any cast iron, on de-concreting the plinth and legs.

2) My inclination is to lift the bed and remove the lathe before tackling the concrete, to leave that to last.

Thing is, the lathe is only one foot away from a wall, and I don’t see how I can get the base struts of an engine crane in far enough.

A bonus for a military historian, like myself, the CovMac was a War Department owned item, still with its War Office serial number.

Well, I am not ashamed of myself, on my first day as an engineer, although it was a bit daunting when I first began.

On the feed gearbox, I can move the gear lever, but the lever to the right of that seems seized solid. The spindle turns, and the lead screw does, too. The apron wheels nicely, and the slide work. There wis nil backlash in the side slide, but some in the compound slide.

Tailstock was a massive, heavy mother, and so is the back gear guard.

The motor is huge, and hangs off a cast iron plate your could tack a battleship to.

I shall enjoy a few beers tonight.

Many, many thanks for all your help, gentlemen. This would have been so much harder had I not spoken to you all in advance.

There will be two more days; firstly, when I remove the headstock, carriage, and take the bed off its legs, and shackle it down to a pallet. Secondly, we move the bed, and finally get the legs out of the concrete.

Any further help and advice will be very gratefully received, particularly on the nexus twixt cast iron and concrete..

Today, well, I did not break anything, and did not lose anything. Phew!!!

Chris

17 September 2014 at 18:47 #163793Brian Wood

Participant@brianwood45127Hello Chris,

I have followed your progress with great interest. Last time I moved heavy things I used a stack of breeze blocks and hefty lumps of timber cut from a 9 inch deep joist.

You say the lathe is close to the wall. Build a stack of blocks, broad faces up, at both accessible ends, against the wall and on the lathe operators side of the lathe. You will then have 4 stacks all laid broadface up. It needs a lot of blocks for this stage.

With good section angle iron, 3 x 3 inch if possible, but not less than 2 x2 laid vees uppermost, use a hefty jack to lift the bed clear of the leg at one end and lower it onto the angle iron arranged as a bridge between a pair of towers.. Repeat at the other end of the bed.

It should now be possible to inch it out from the wall using suitable lengths of 4 x 2 timber for leverage, it will slide quite easily on the inverted vees. Take it out as far as you need to get the engine crane legs in position, with the hook suspended from the point closest to the hydraulic ram and best able to take the weight.

If you are clear of the grouted in legs and the crane is both stable and man enough for the job, pull out the angle irons and lower the bed down onto baulks of 4 x 2 on the floor.

Now it can't move or fall over. Remove all the debris of battle, blocks, angle iron etc to get a clear working area and space to move it across the floor to the loading point.

Stopping swing and pendulum action with ropes tying both ends of the bed back to the crane will help before finally lifting it high enough to get it onto the transport.

Best of luck

Brian.

Edited By Brian Wood on 17/09/2014 18:47:50

Edited By Brian Wood on 17/09/2014 18:49:16

17 September 2014 at 19:05 #163794CHRISTOPHER MILLS 1

Participant@christophermills1Brian,

Many thanks for that; I will give this lifting and shifting method every consideration. Any thoughts on de-concreting the legs and plinth?

Chris.

17 September 2014 at 20:07 #163802Brian Wood

Participant@brianwood45127Hello Chris,

Use a decent 1 inch wide, 8 inch long cold chisel and lump hammer to chip away the grout, starting about 1 -1.5 inches away from the leg. Don't tap at it, give it some wellie.

Chip towards the leg and step the cut back away from the leg if needed to deepen it. It should come away in satisfying chunks if you work all round the leg. You might also find the leg with the deepest grouting is bolted down to the floor. If you can't shift the bolt head with a well fitting ring spanner, belt the head end, using a brass drift to protect it from bruising and try again. The shock may well have 'sprung' the thread .

If the installation is old [WW 2] the bolt head may be leaded into the floor, it was the practice in those days.

If all else fails, hacksaw off the bolt head or split the nut depending on what you find

Regards

Brian.

Edited By Brian Wood on 17/09/2014 20:08:21

17 September 2014 at 20:17 #163804CHRISTOPHER MILLS 1

Participant@christophermills1Hi Brian,

I am happier, by reading this advice. The lathe was put into position in the early 1990s, we believe. It looks very ad hoc, and I will be surprised to find it bolted down, too.

This was an old boy, and I don't think he considered the lathe might survive him, and be worked. It has, and it will.

Whacking the 'crete hard, rather than tapping, encourages me that I will not shatter cast iron.

It is good to talk to real engineers. I feel welcomed.

Best.

Chris.

17 September 2014 at 20:44 #163808CHRISTOPHER MILLS 1

Participant@christophermills1Brian,

Just to clarify: We are agreeing that concrete does not have the tensile strength to break cast iron in which it sits in contact, when shattered by a cold chisel?

Best.

Chris.

-

AuthorPosts

- Please log in to reply to this topic. Registering is free and easy using the links on the menu at the top of this page.

Latest Replies

Home › Forums › Beginners questions › Topics

-

- Topic

- Voices

- Posts

- Last Post

-

-

Air source heat pumps

Started by:

Plasma in: The Tea Room

- 8

- 10

-

9 March 2025 at 17:43

Robert Atkinson 2

Robert Atkinson 2

-

Vibration and exploring the Fast Fourier Transform with CAD

1

2

Started by:

SillyOldDuffer in: CAD – Technical drawing & design

- 11

- 49

-

9 March 2025 at 16:27

Julie Ann

Julie Ann

-

following a thread…?

Started by:

Chris Kaminski in: New Forum Software questions, comments and Test Threads

- 2

- 3

-

9 March 2025 at 16:11

Chris Kaminski

-

What’s this for…no.10?

Started by:

beeza650 in: Beginners questions

- 5

- 5

-

9 March 2025 at 14:55

KenL

-

3 1/2″ gauge LMS Jubilee 4-6-0

Started by:

amorrison in: Locomotives

- 5

- 7

-

9 March 2025 at 14:51

Nicholas Farr

Nicholas Farr

-

How to sell my workshop?

Started by:

Tony Martyr in: General Questions

- 7

- 7

-

9 March 2025 at 14:21

V8Eng

-

What’s this for…no.9?

Started by:

beeza650 in: Beginners questions

- 6

- 7

-

9 March 2025 at 13:36

Nicholas Farr

Nicholas Farr

-

George Thomas retractable slide for the myford.

Started by:

Brian Abbott in: Workshop Tools and Tooling

- 16

- 20

-

9 March 2025 at 12:40

Chris Kaminski

-

House painting

Started by:

gerry madden in: The Tea Room

- 8

- 10

-

9 March 2025 at 12:29

Colin Bishop

Colin Bishop

-

FB2 Clone – aligning the column

Started by:

Diogenes in: Manual machine tools

- 9

- 16

-

9 March 2025 at 10:35

Graham Meek

-

Telescope Leadscrew Advice

1

2

Started by:

Dr_GMJN in: General Questions

- 10

- 29

-

9 March 2025 at 10:23

Michael Gilligan

Michael Gilligan

-

DRO Origin Setting

1

2

Started by:

Peter Cook 6 in: Beginners questions

- 23

- 45

-

9 March 2025 at 09:37

peterhod

-

Kelsey Media buys Mortons titles

1

2

3

Started by:

Colin Bishop

in: Website Questions, Comments, and Suggestions

Colin Bishop

in: Website Questions, Comments, and Suggestions

- 20

- 65

-

8 March 2025 at 18:39

SillyOldDuffer

-

Raglan vertical milling machine

Started by:

roger kerry in: Manual machine tools

- 6

- 10

-

8 March 2025 at 17:45

bernard towers

-

My week this week! My workshop videos

1

2

…

11

12

Started by:

Phil Whitley in: The Tea Room

- 13

- 281

-

8 March 2025 at 16:02

Phil Whitley

-

How to correctly use a height gauge

1

2

3

Started by:

Graham Wharton in: Workshop Techniques

- 23

- 57

-

8 March 2025 at 15:37

Howard Lewis

-

Rotary table digital readout

Started by:

petetwissell

in: Workshop Tools and Tooling

petetwissell

in: Workshop Tools and Tooling

- 6

- 10

-

8 March 2025 at 11:00

petetwissell

petetwissell

-

24cc DIESEL ENGINE FROM SOLID

Started by:

dean clarke 2

in: I/C Engines

dean clarke 2

in: I/C Engines

- 8

- 17

-

8 March 2025 at 08:44

KEITH BEAUMONT

KEITH BEAUMONT

-

Oil grooves for bushings?

Started by:

keith hodgson in: Help and Assistance! (Offered or Wanted)

- 11

- 14

-

8 March 2025 at 07:38

JasonB

JasonB

-

E Bay shot in foot

Started by:

duncan webster 1 in: The Tea Room

- 10

- 17

-

8 March 2025 at 00:08

duncan webster 1

-

Seen on FaceBook

Started by:

Vic

in: The Tea Room

Vic

in: The Tea Room

- 4

- 6

-

7 March 2025 at 21:14

Chris Kaminski

-

Building Wilding’s Tower Clock

Started by:

Chris Raynerd 2 in: Clocks and Scientific Instruments

- 7

- 25

-

7 March 2025 at 19:04

gerry madden

-

Classifieds photo problem?

Started by:

Mike Hurley in: Website Questions, Comments, and Suggestions

- 3

- 3

-

7 March 2025 at 11:50

JasonB

JasonB

-

Resize photos W11

Started by:

duncan webster 1 in: Help and Assistance! (Offered or Wanted)

- 11

- 14

-

6 March 2025 at 18:30

duncan webster 1

-

Help identifying some model engines

Started by:

Mat Dodge in: General Questions

- 2

- 7

-

6 March 2025 at 18:08

JasonB

JasonB

-

Air source heat pumps

-

Latest Issue

Newsletter Sign-up

Latest Replies