Thanks gentlemen.

Neil, the chuck you have assessed spot on – I have no real idea yet of how it comes off, despite Phil Whitley and Brian Wood both trying their very best to elucidate for me. I cannot find a spindle lock mechanism, as yet.

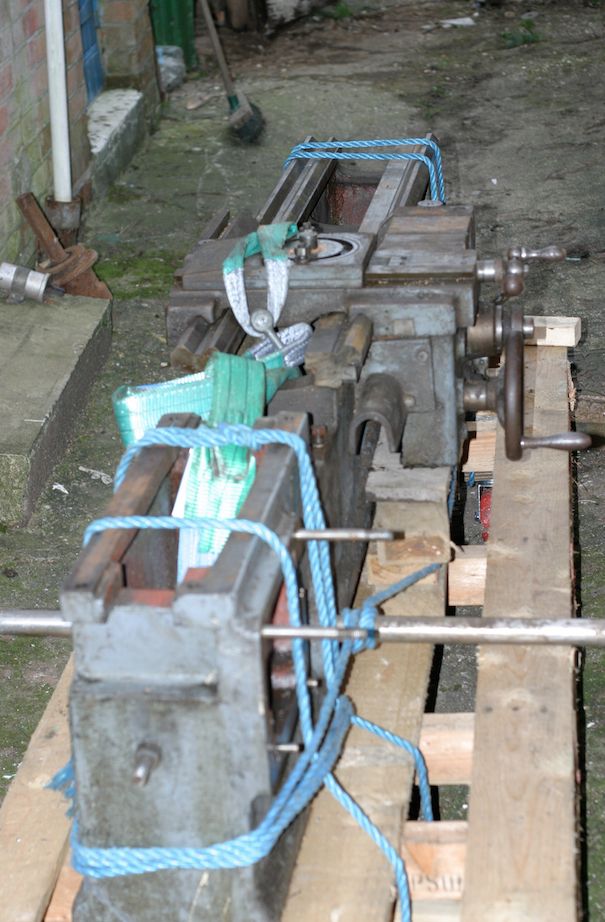

Final Note – Moving the CovMac – To go back to the beginning, here is reminder of the lathe as I took it on. After spending perhaps all of 18 months looking for a suitable, old metal lathe to restore, this was my first choice:

And t'other end:

The 2×2 timber is holding the roof up, and sheer amount of general neglect, and filth, are plain to see. Sadly, it seems the previous owner, a professional engineer, who died in 2012, aged 84, was for long, owing to age or infirmity, unable to give the lathe the TLC it needed. That this wonderful industrial sized lathe spent its last 30 years in a filthy old garden shed is a wonder to me.

CovMac Goodies: – With the lathe came a truly amazing storehouse of accessories and tools – five chucks, five face-plates, including the monster 24", a stout centre-steady, a number of gear change wheels, enough cutting tools, drills and boring bars to last me two lifetimes, 50 metal files, two 6" Record engineer vices, an anvil, taps and dies, dozens of hand tools, wrenches and pliers, and a selection of specialist items yet to be identified, one small vernier and an Ape Microball, and the previous owner's signed copy of "Machinery's Guide" – 1942 – very contemporaneous to the lathe itself . Plus, I have a hefty selection of metal bar material. It took three trips in my VW Passat estate to remove it all.

Thus, I reckon I may have enough to begin a bit of metal turning!

This started out as a museum project, from which I hoped to learn some engineering, and it has worked extraordinarily well, so far.

This 11 weeks which has elapsed, since I took on the lathe, has been expedited by the amazing generosity of heart shown me by members of this forum. It has been so heartening to get such help.

I have to return to my own professional commitments, presently, but I will begin the thread again, in the New Year, with restoration of the machine, which has already begun in small parts.

I will be doing a bit more research into Coventry Machine Tools Limited – there is little known on the firm so far. They were never primary lathe specialists, but better known for their heavy forging machinery. Their dates seem to be about 1936 – 1953. There is some material in Coventry City Archives, which may throw us useful light. There are known but 5 surviving lathes made by the company – one is in Australia, the only known 17" head example.

Might I wish all you engineers a Merry Christmas, and a Happy New Year, 2015.

Many thanks.

Chris Mills.

Edited By CHRISTOPHER MILLS 1 on 07/12/2014 13:09:49

Doug Goding.