Hello, I haven't updated this thread for a while so here we go.

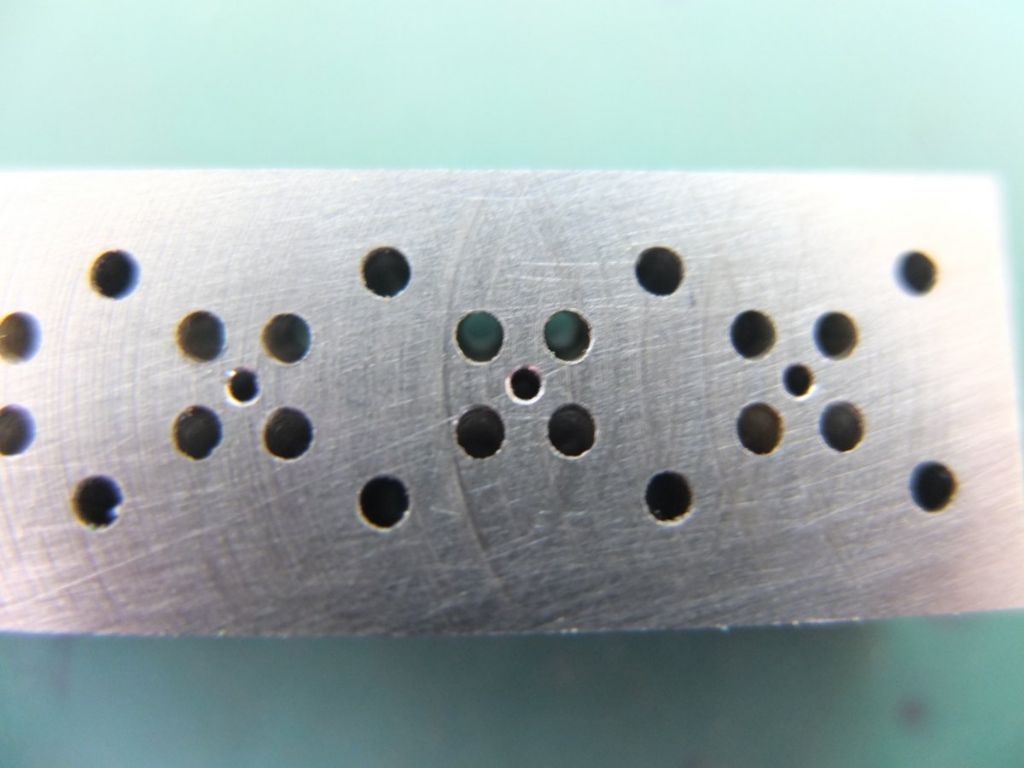

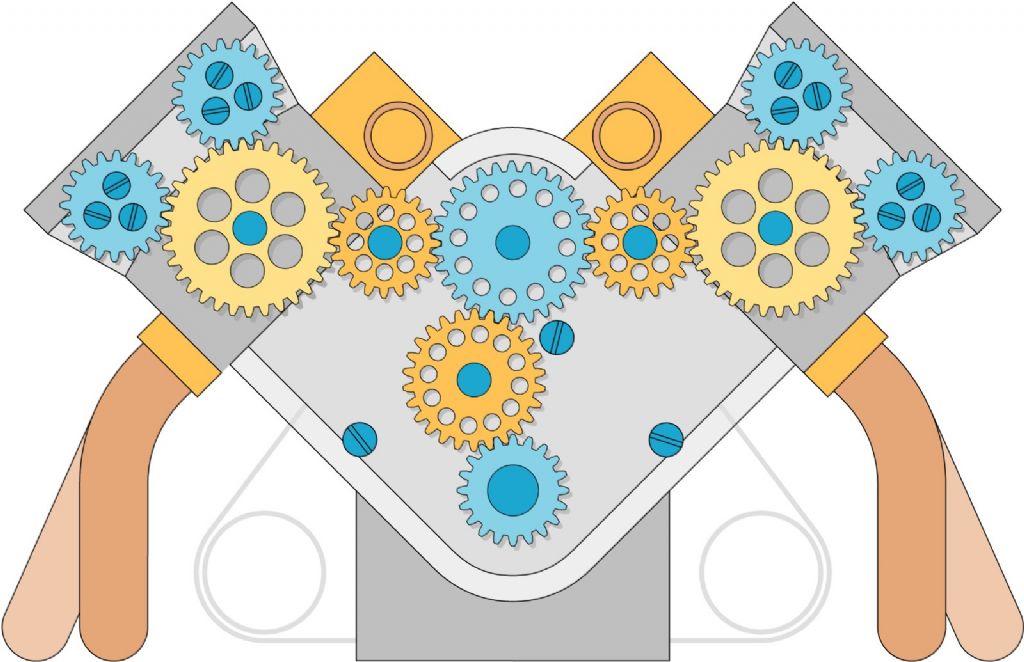

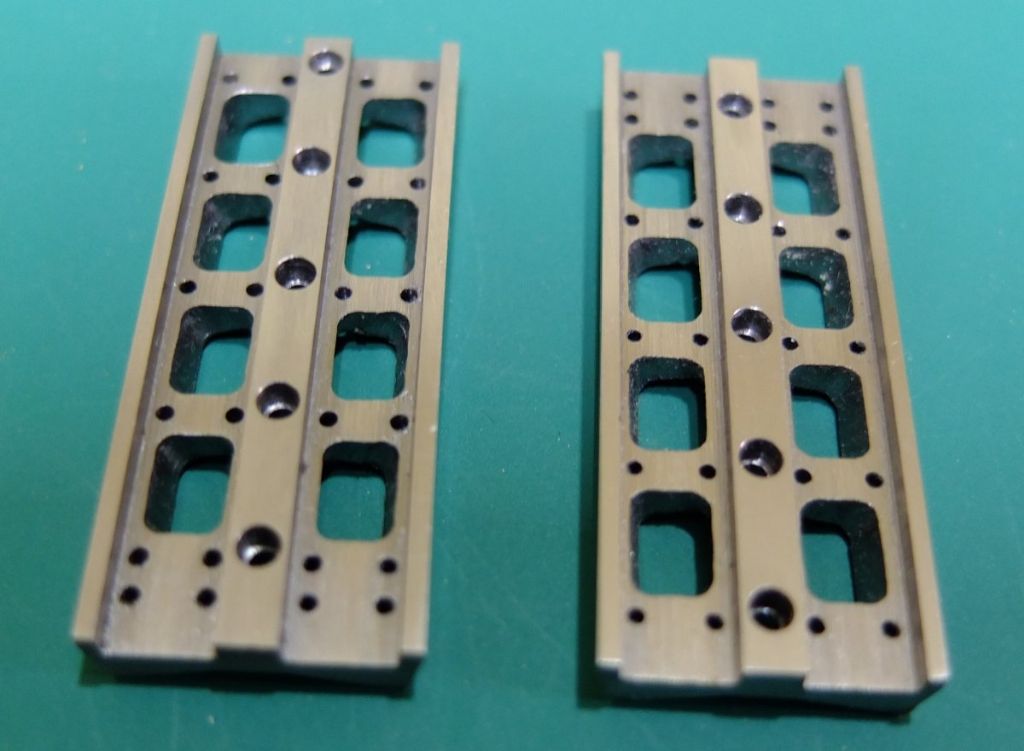

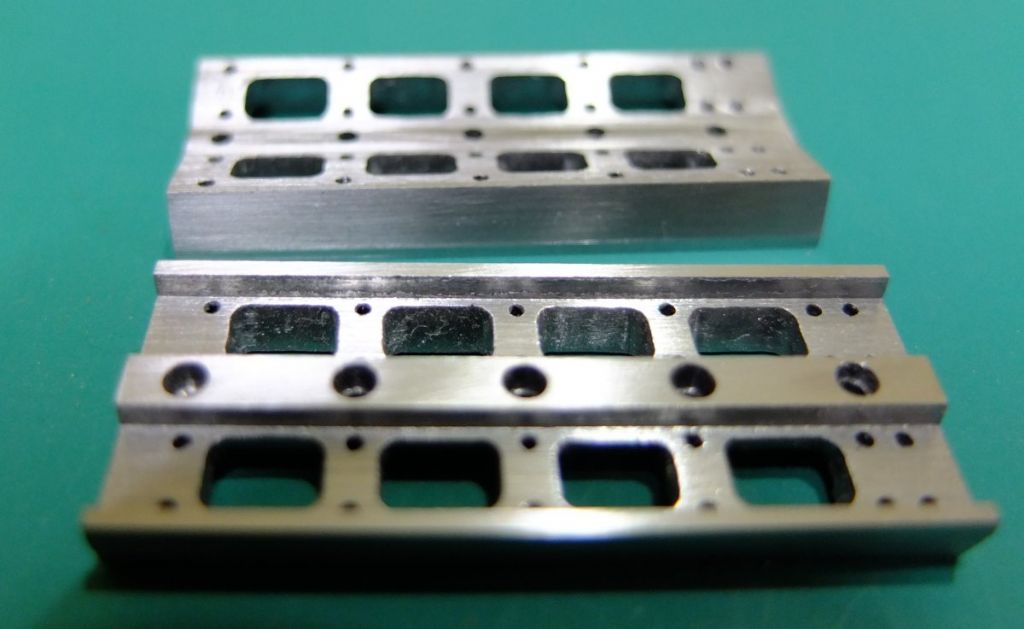

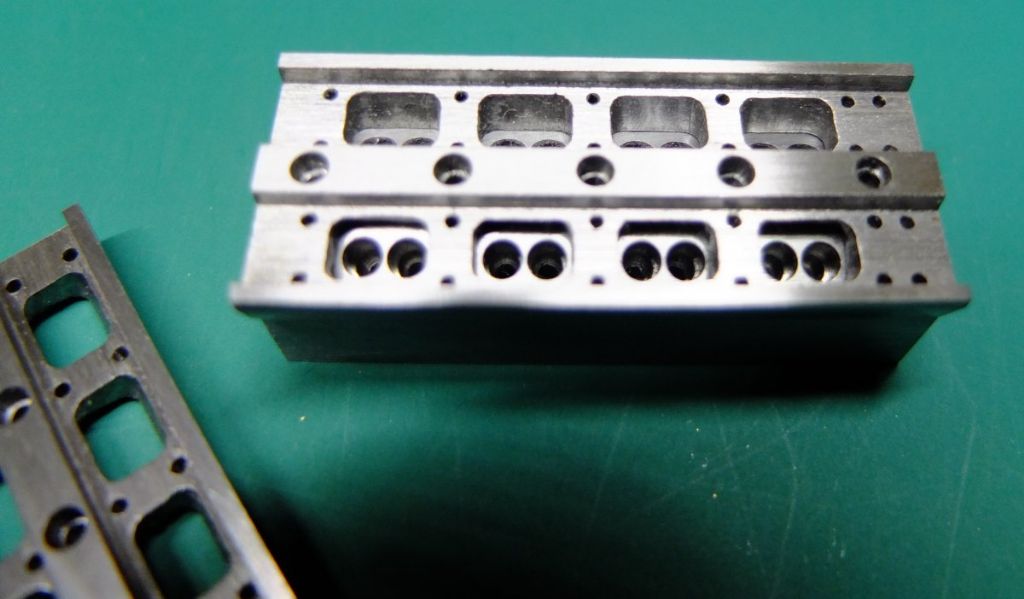

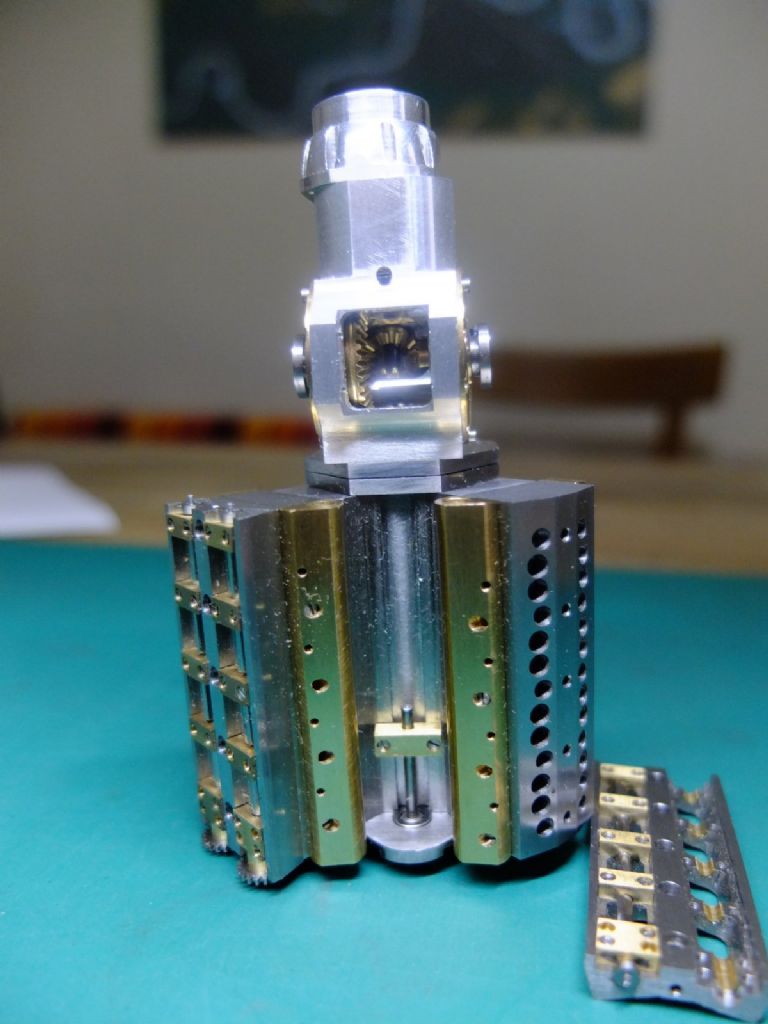

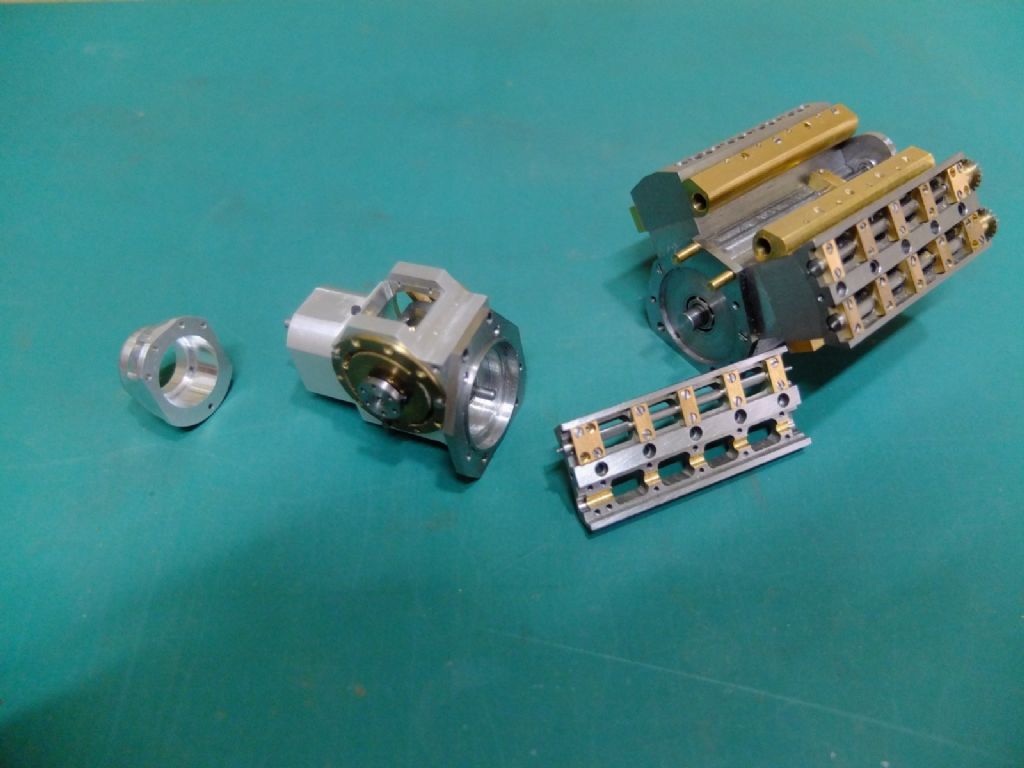

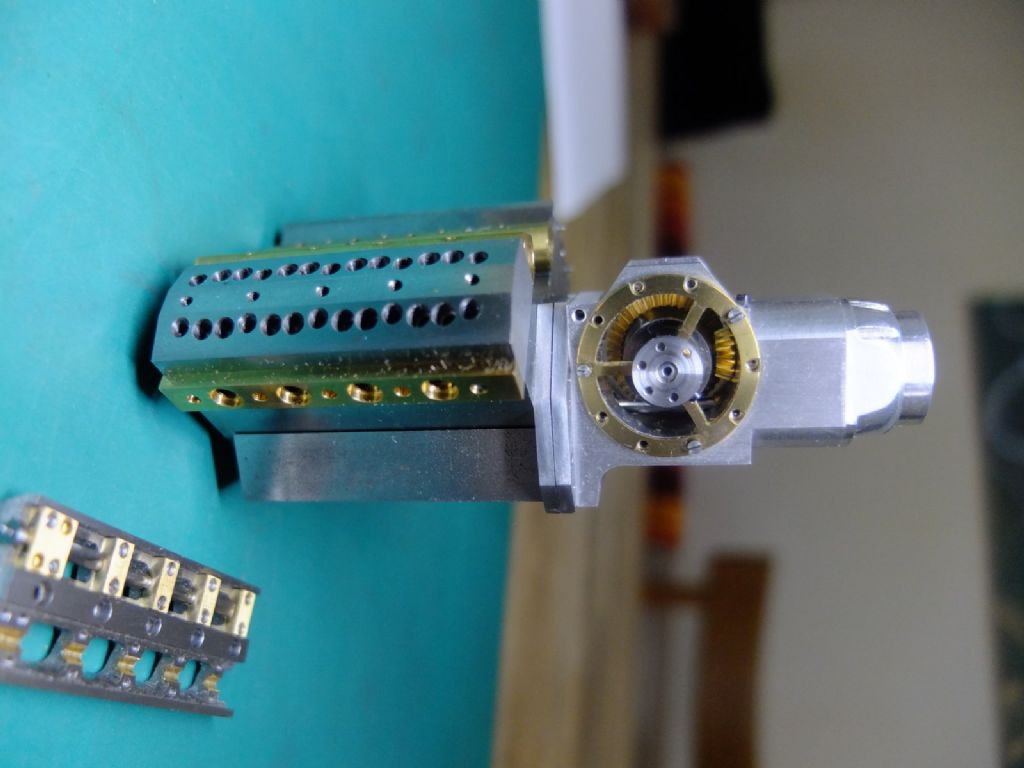

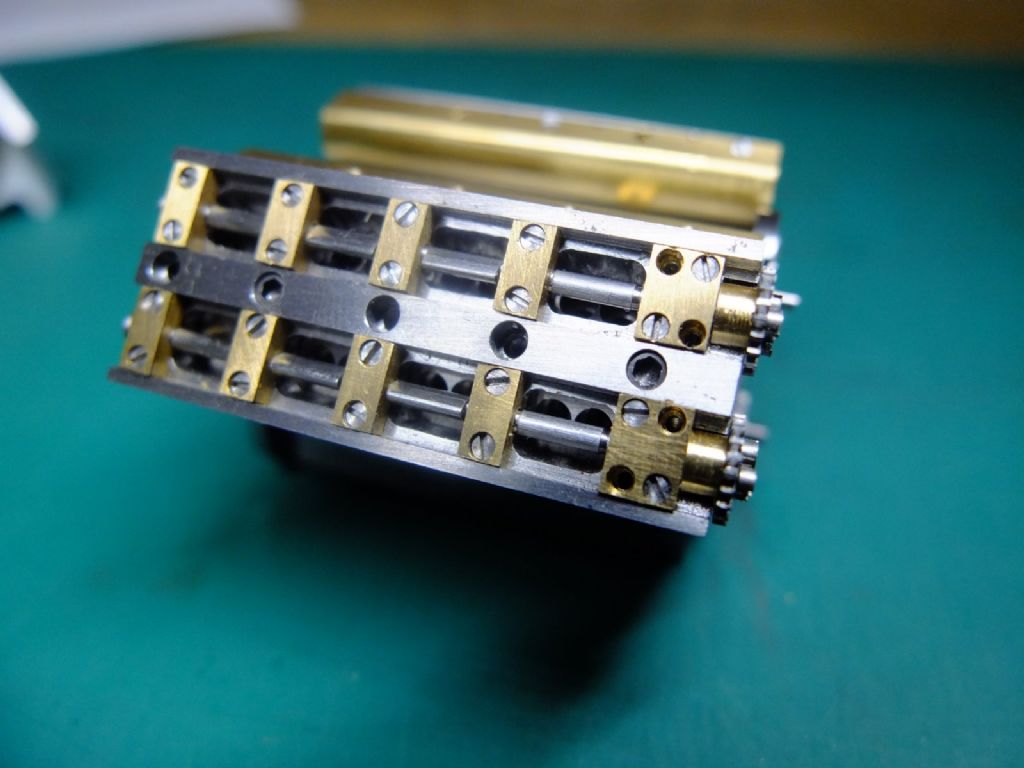

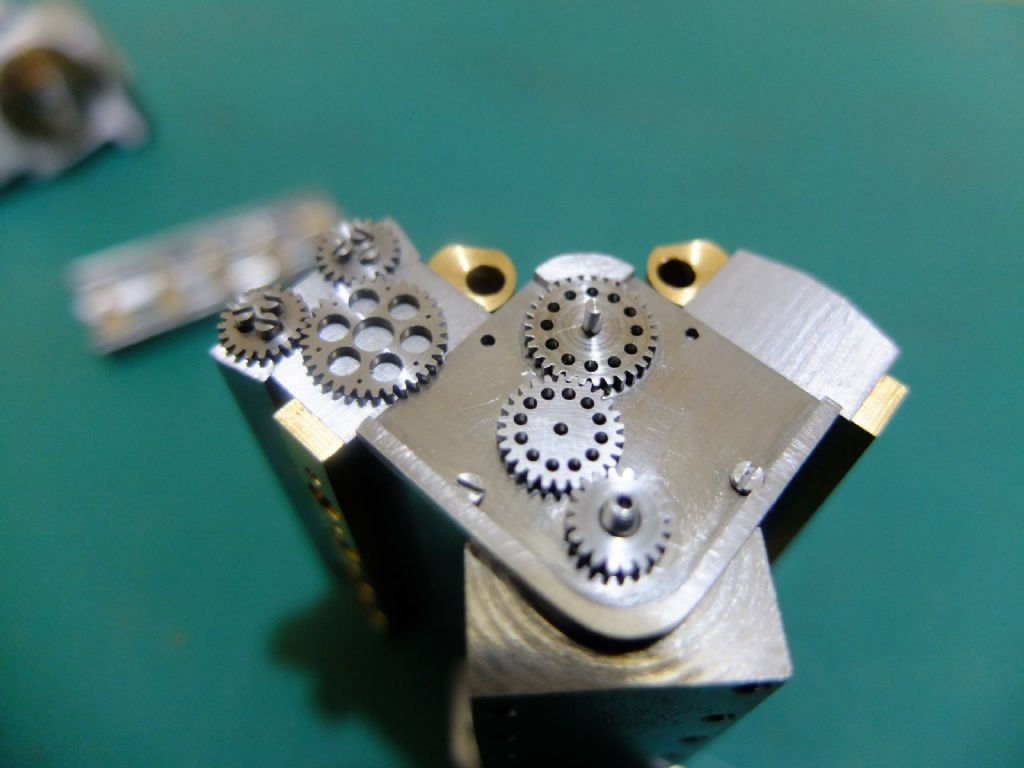

I have been cutting the gears for the cam gear train, and lots of spares.

There are 11 gears in the train in 4 different sizes.

They all came out ok apart from the 20 tooth wheels which I didn't give enough depth of cut. Only a couple of thou but it's made a difference at Mod 0.3. This is unfortunate as 7 of the 11 gears are 20 tooth! I'm just going to have another go.

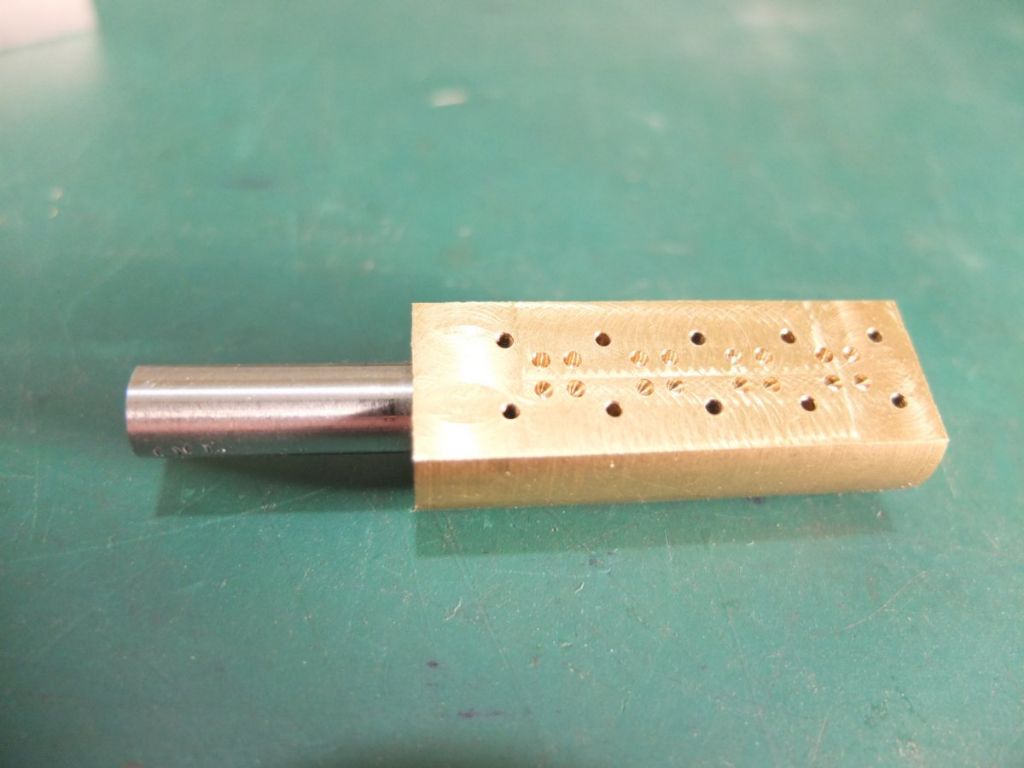

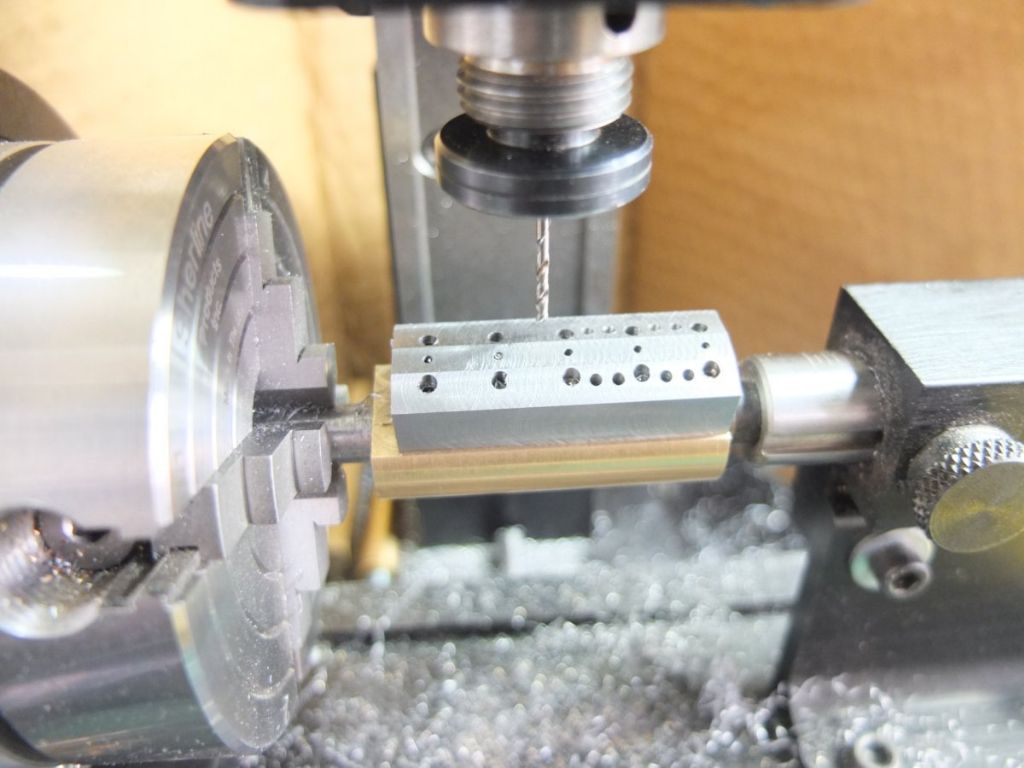

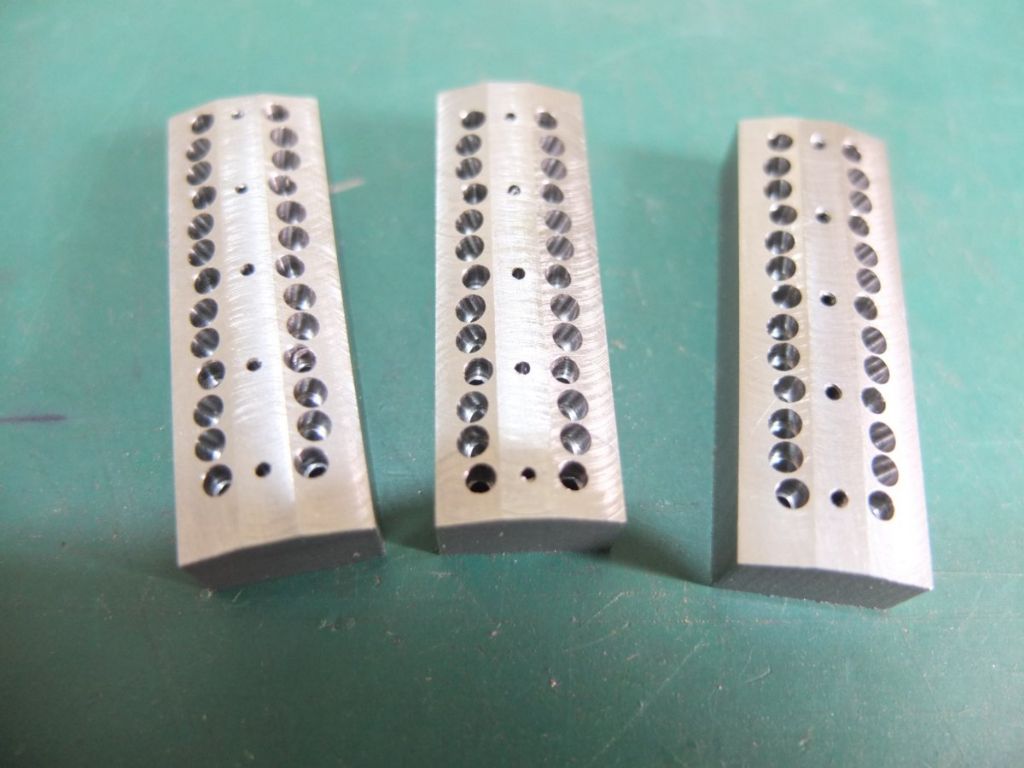

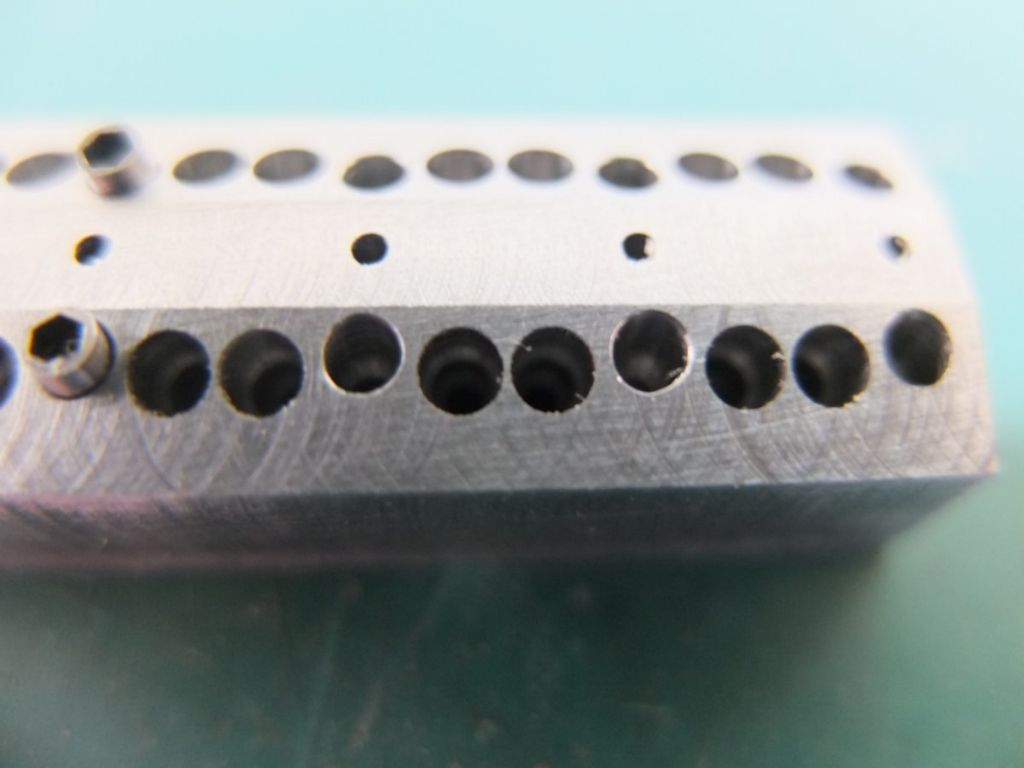

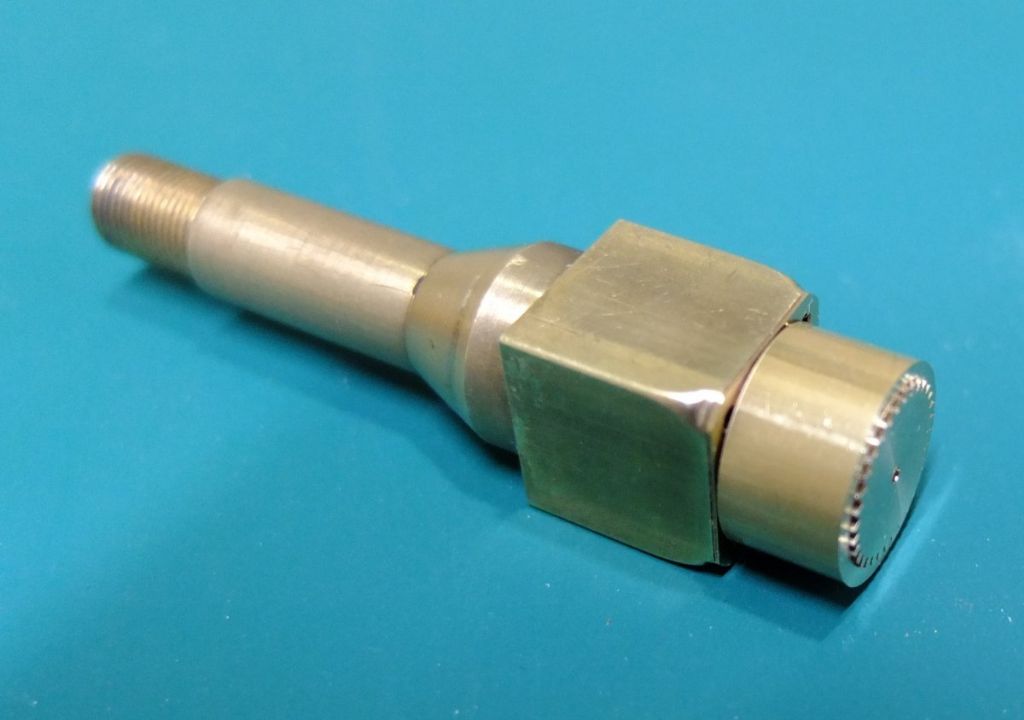

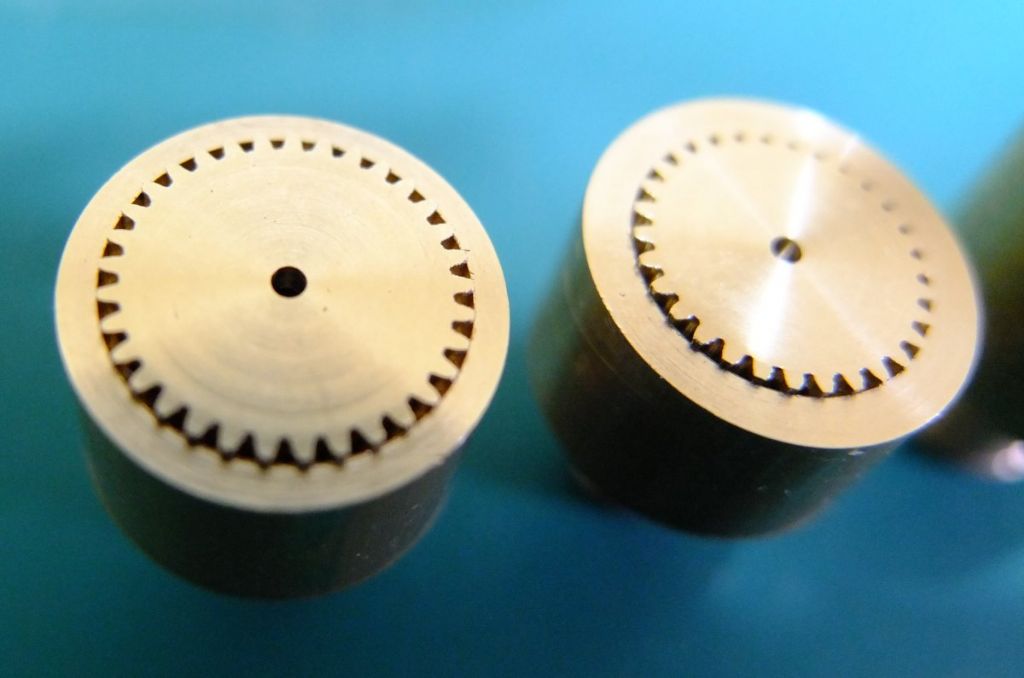

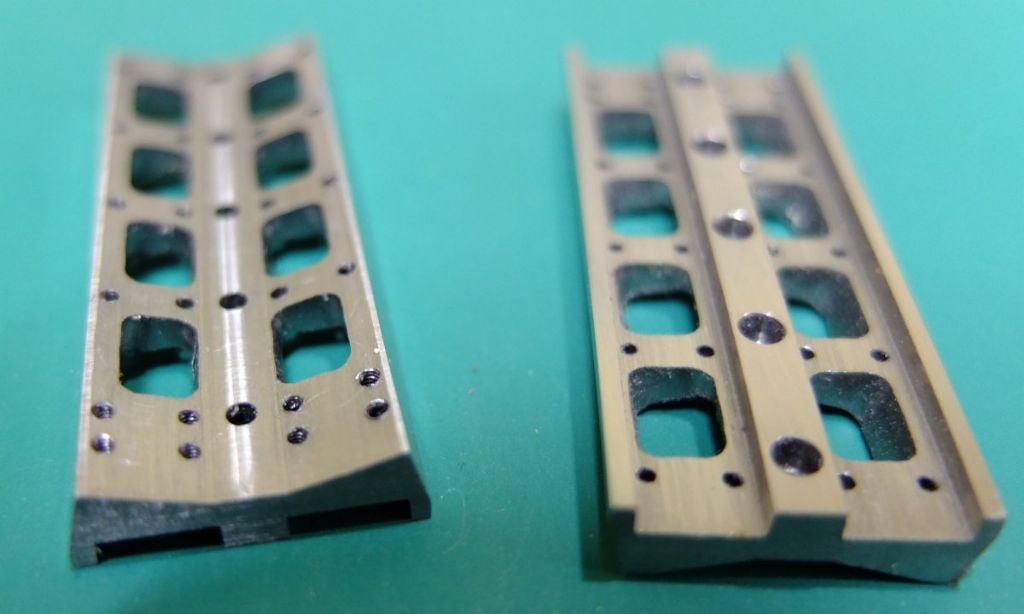

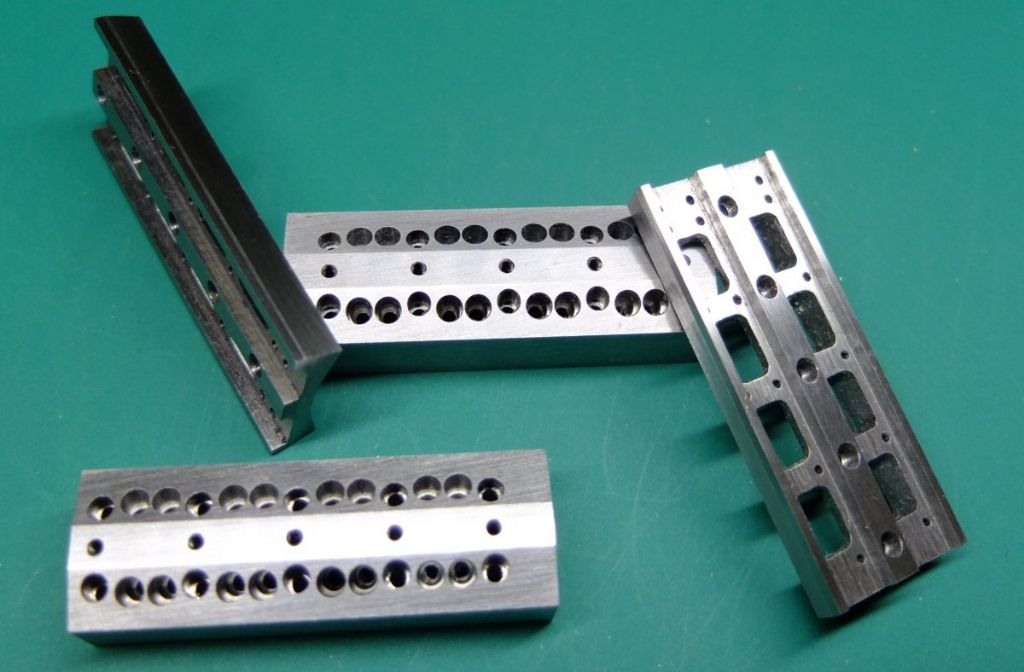

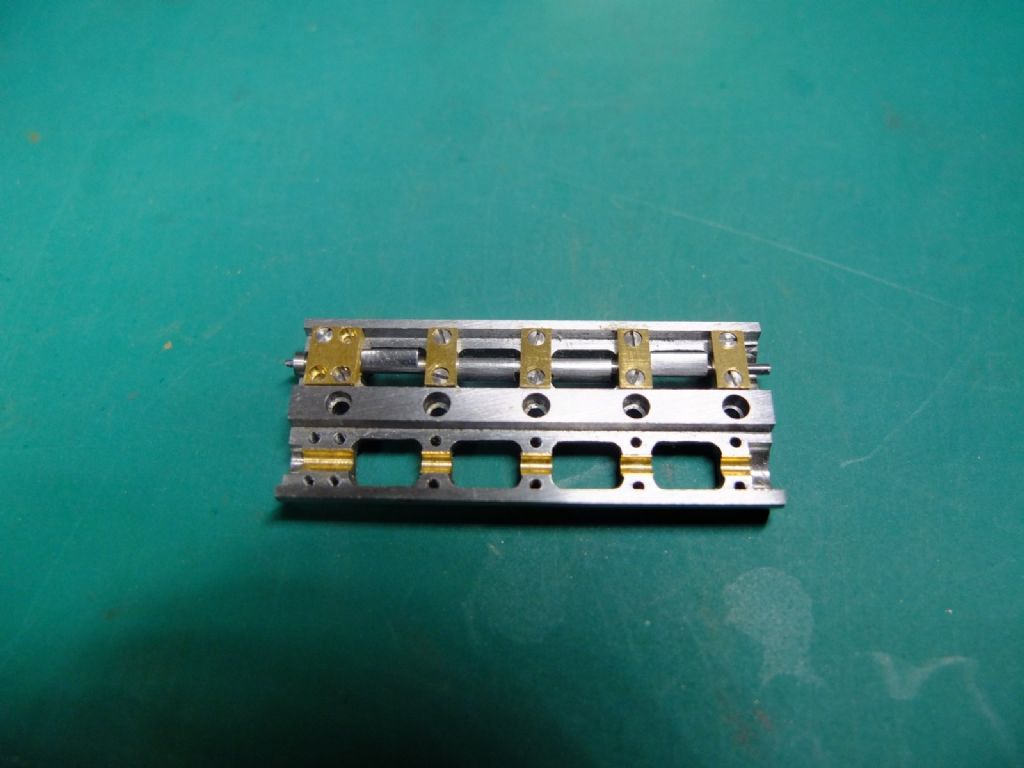

To hold the wheels for facing, drilling etc. I made pot chucks for each size.

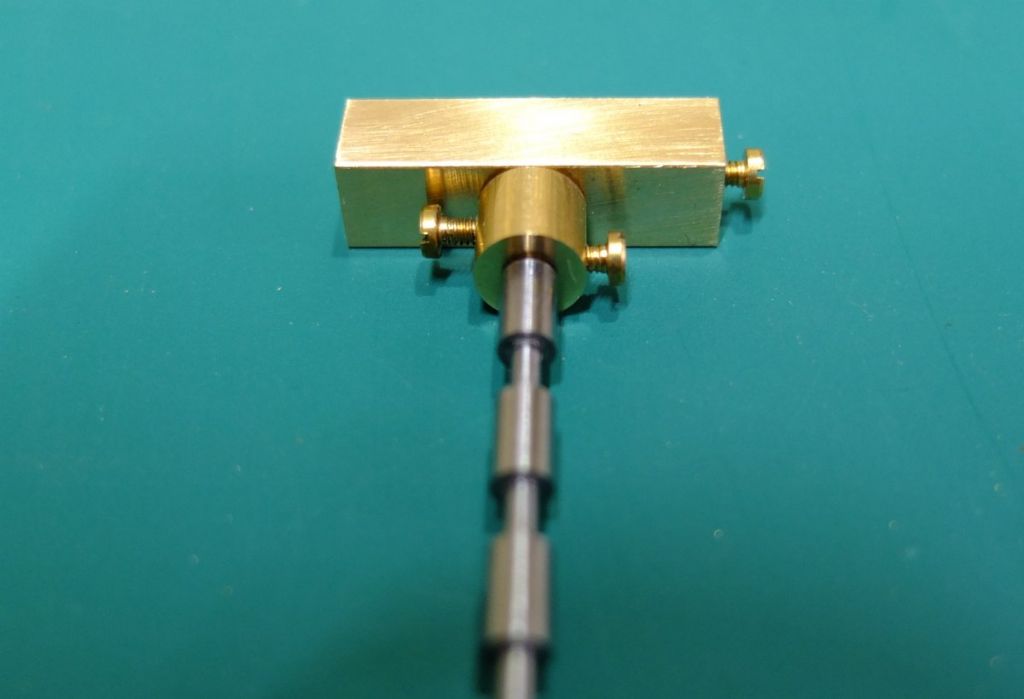

These just screw into a 8mm collet thingy.

They give a nice friction grip that doesn't do any damage. You don't need glue or shellac.

I made a spare of course.

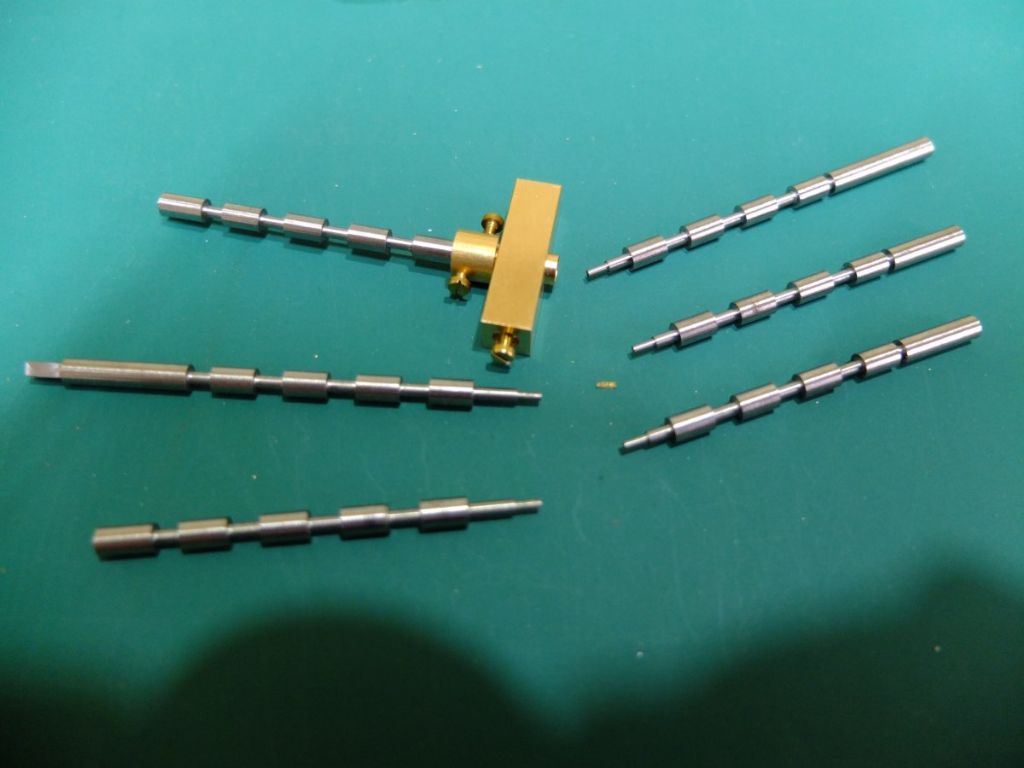

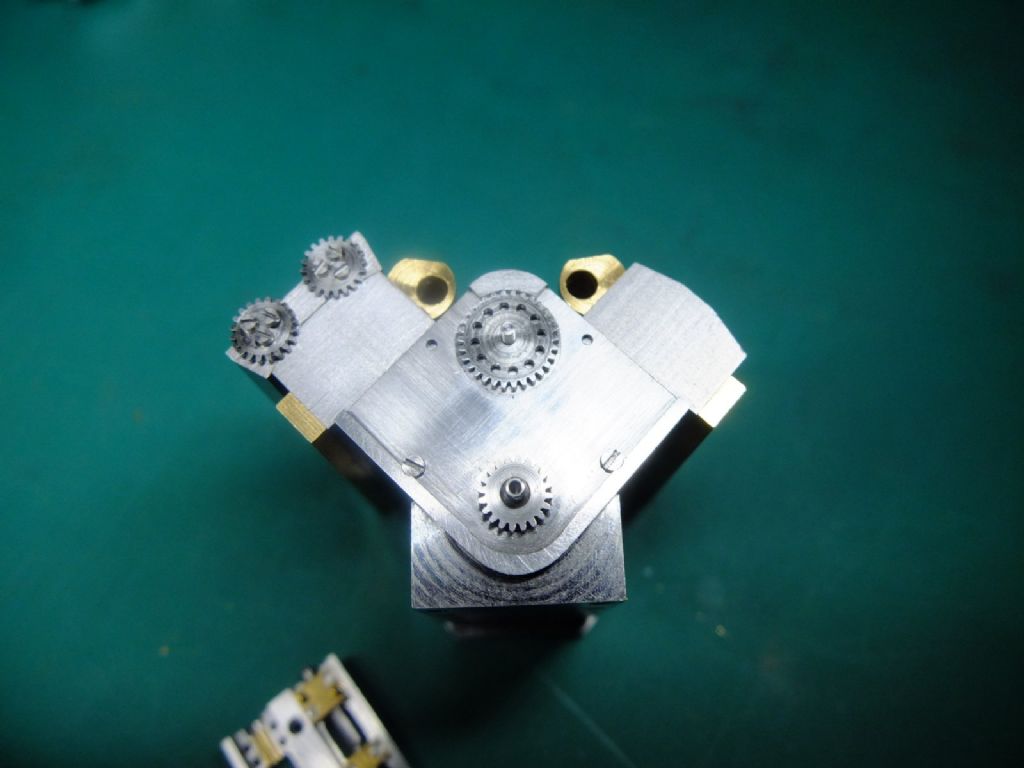

I centre drilled one of each size as "test" gears. I'll fix an arbor to each and put them in my depthing tool and see how they mesh.

More soon.

Steve

Edited By Steve Crow on 07/02/2021 18:04:56

Edited By Steve Crow on 07/02/2021 18:05:53

Ady1.

Ady1.