Looks OK to me and the airgun website shows what pitches are available, identifies approximations (in red) that might be close enough for a short thread, and explains the maths:

Conventionally, Imperial gearboxes are tweaked to produce metric (or vice versa), with a 127 toothed gear. This because there are 25.4 millimetres per inch and half 254 is 127. The conversion is exact, but a 125 toothed gear may be too big to fit the banjo, hence a 63 toothed gears may be used instead. 4 x 63 is 252, close enough to 254 for short thread engagements to fit acceptably. However the error becomes progressively more serious and after about 8 to 10 threads the 63 gear bodge becomes troublesome.

Most modern lathes, including I think all Far Eastern hobby machines, do metric and imperial without a special gear pair like 52:44, 63:1 or 127:1 Instead, the change gear set provided is capable of producing the ratios needed as a mix of spot-on and close approximations. The Imperial approximations on my Metric lathe are all better than 63:1, plenty good enough for most purposes, but I would check the actual accuracy of a ratio before trusting it to turn a long Imperial Thread. The change gears provided with the Imperial version of the same lathe are slightly different, and owners should check the actual ratio before trusting one to turn a long Metric Thread. Is the ratio spot-on or an approximation and how good is the approximation?

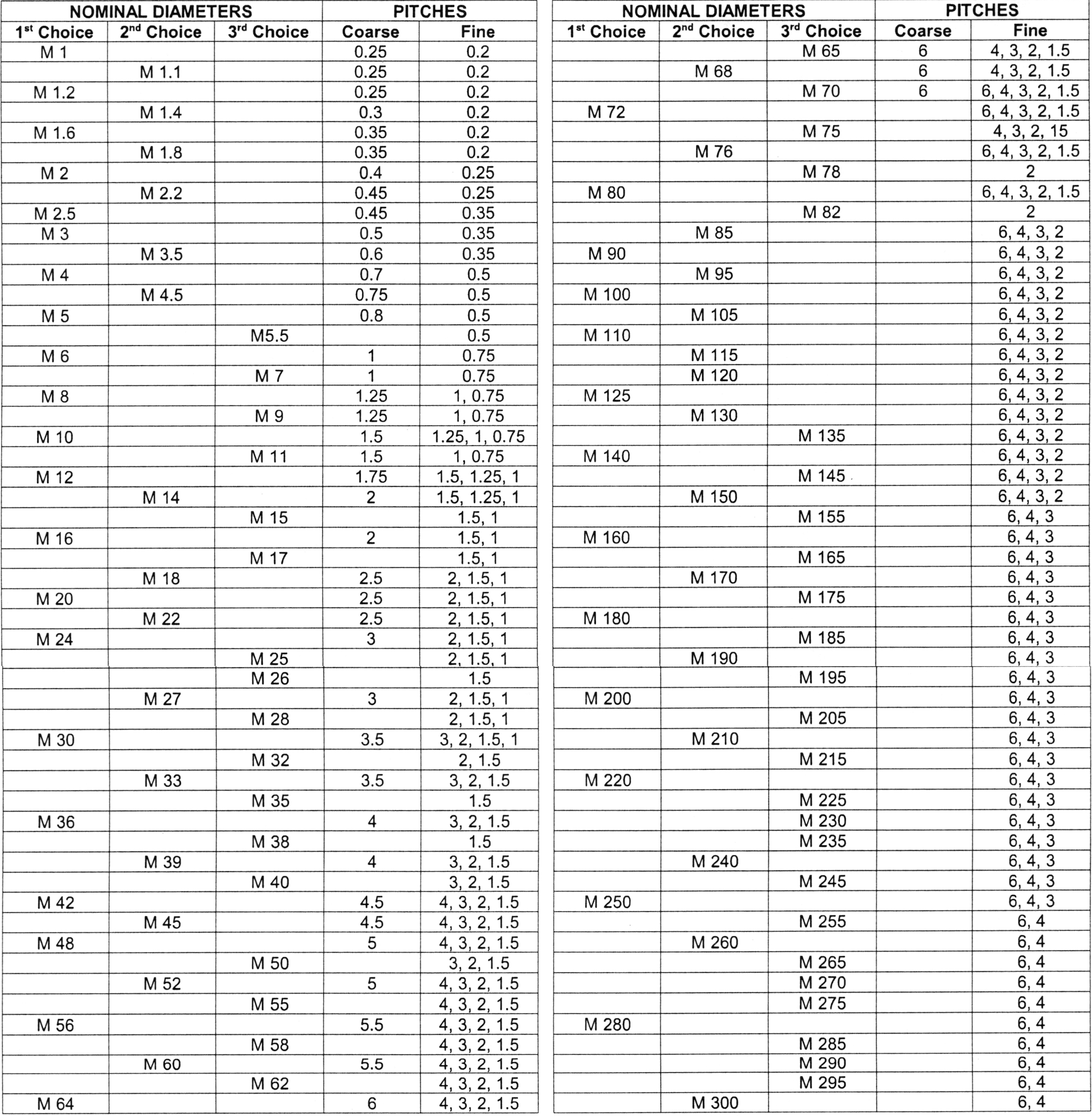

On the Atlas, 52:44 provides a useful selection of metric threads, but not a full set as this list shows. The shortfall may not matter!

Finally, 52:44 isn't a magic combination guaranteed to work on all Imperial lathes. It might, but it depends on the lead-screw and gearbox ratios. Someone has to do the maths!

Dave

Edited By SillyOldDuffer on 26/10/2022 10:34:32

duncan webster 1.