Being an inquisitive soul, I have been making some experiments with the relative strengths of Loctite.

First to set the scene. Some of you will be familiar with this as being the mandrel gear for a pre-historic Myford S7 with the Mk 1 QCGB,

xxxx

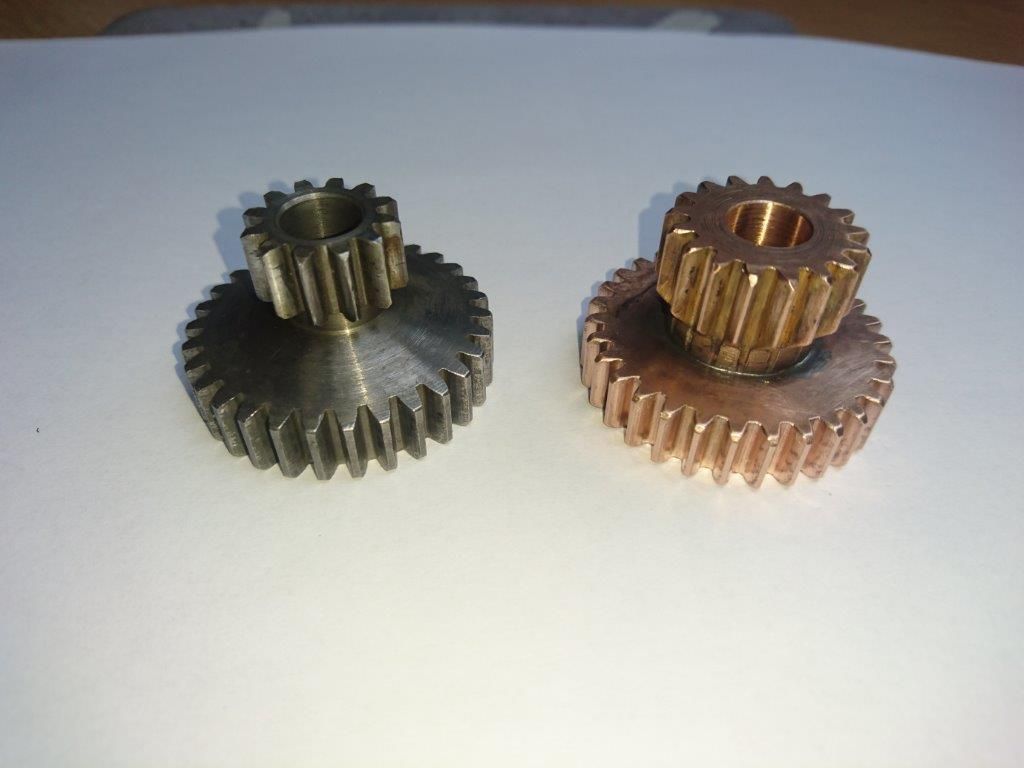

The one on the left is the proprietary Myford 30/12T original, the one on the right is my version of the same thing with 17 teeth on the smaller gear. I made a 17T gear on a stub shaft, and soft soldered a 30 T gear onto the stub.

I was curious to know if I could have used Loctite, and how strong is the soft solder anyway.

So here is a dummy gear cluster, with hexagons cut instead of the two gears:

xxx

For the sake of completeness here is a picture of the two component parts:

xxx

There are, as you will have noticed, remnants of Loctite on the interface between the two parts. To scale the area of the interface, that stub is 0.625 OD +/- about 3 tenths, and the bore is 0.375 ins long by 0.625 OD – minus nothing plus maybe 5 tenths. So a "place fit" rather than a push fit. I didn't make any attempt to polish the mating surfaces – the bore is straight off a reamer and the stub is straight off the lathe tool, which is exactly how I made the parts of the original gear cluster.

So I tried assembling the two parts with differing grades of Loctite. Then I broke them apart in torsion holding the large nut (41 mm a/f) in the vice and applying a measured torque to the 19 mm a/f "pinion" with a torque wrench. To be strictly fair the torque is applied only one sided – so it is a cantilever load on the join – but that is how the assembly will be used in real life. I applied successive and increasing torques to the assembly increasing in 5 ft-lbs increments until the joint failed. The two torque wrenches I used are in good condition but not formally calibrated and are the micrometer type.

This is what I measured:

Loctite 638 12 hours cure, failed at 60 ft-lbs, withstood 55 ft lbs.

Loctite 638 repeated, 17 hrs cure, same result

Loctite 243 (Nutlock) 2 hrs cure failed at 15 ft-lbs, withstood 10 ft-lbs

Loctite 542 (Thread Sealant), 3 hrs cure, failed at 30 ft-lbs, withstood 25 ft-lbs.

I then tried soft-soldering the two parts together, using 60/40 resin cored solder with additional active flux, this failed at 110 ft-lbs withstood 105 ft-lbs.

If anyone can suggest other grades of Loctite which might be of interest to get into the magic three figures I'd be interested to try them out.

Rgds Simon

Simon Williams 3.