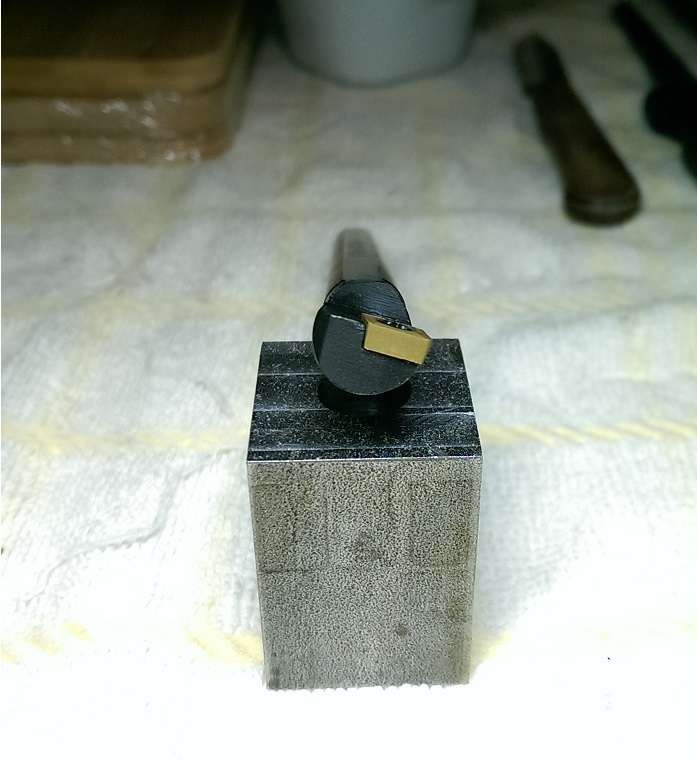

I fully agree with Jason about using the sharp polished GT type inserts for smaller cuts on steel. They are sharp like honed HSS and intended for aluminium, but very good with steel. They can stand a certain ammount of interrupted cutting, I like them when boring soft jaws, and thats about as interrupted as you can get. The blunt inserts work best when taking deep cuts, but need rigid support that larger machines have. An intermediate grade would be for stainless steel,which is quite fine edged. Carbide shanked boring bars are better than steel ones because of their stiffness and density, but unforgiving if mistakes are made. I am lucky to have a supply of Densimet at the museum in ground bar form, 1/2″ and 12mm which has both the stiffness and density of carbide bars, but is not brittle and it can be machined. I have made some boring bars for lathes and also for mill boring heads. Here is a pic of one of the boring head tools.

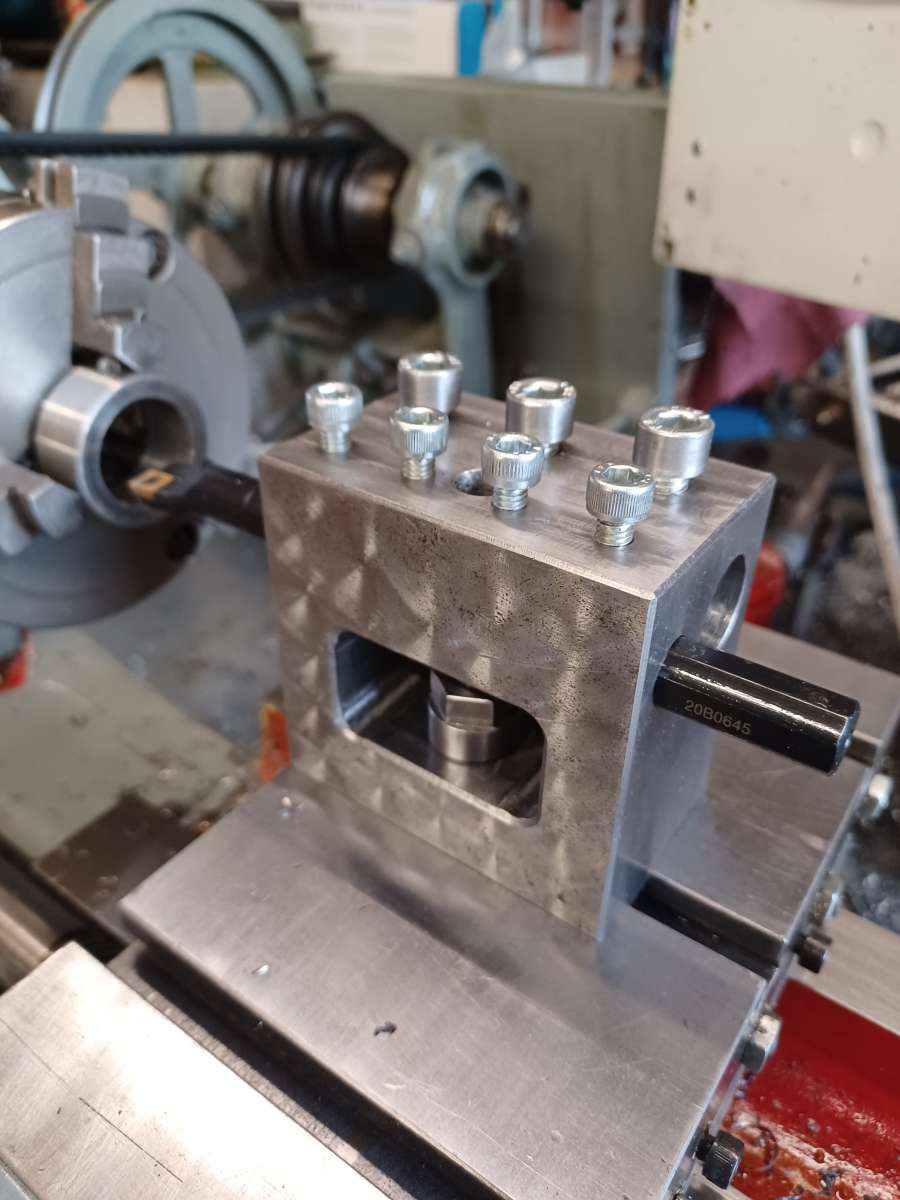

I also take advantage of the boring and threading bars having the tiip height at half the bar size like DG, I was surprised that he was informed that you need a 20mm threading bar for er16 type inserts, I think I have smaller diameters as well as 20mm that take them, I will check tomorror when I get back to the museum, if I remember.

MikeK.