Hello,

Hello,

Please forgive the quality of the images, but hopefully will give you an idea.

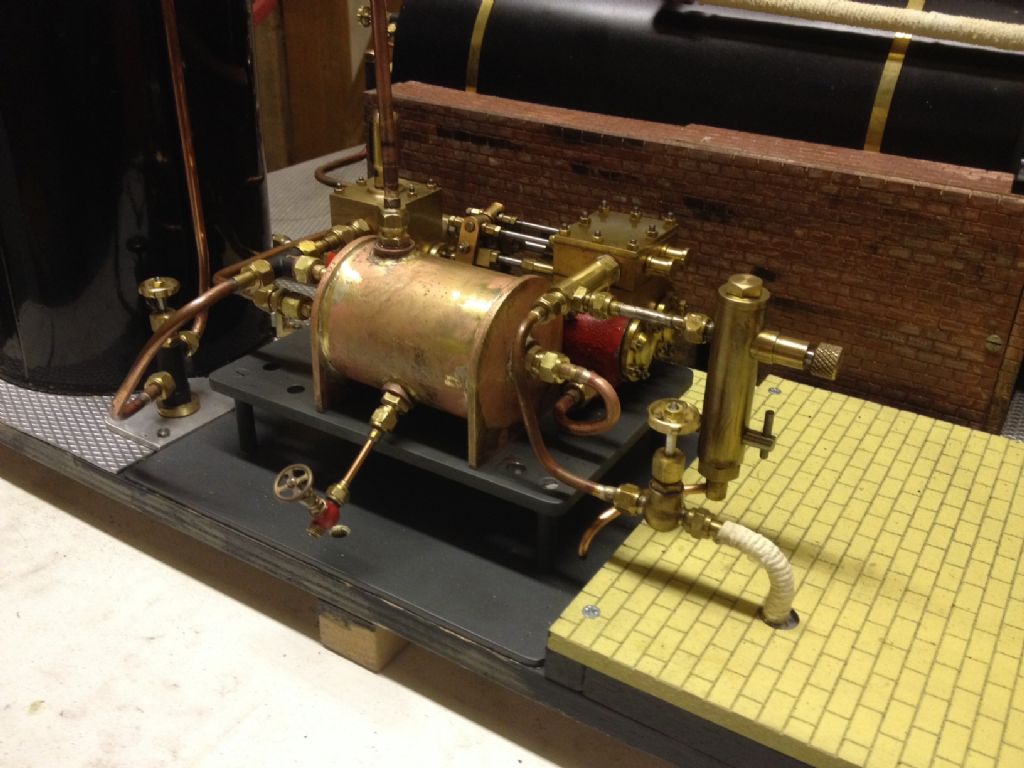

Making a working scale replica of a Cornish boiler would, given the original design of a centre flue containing the furnace and galloway cross tubes with two exterior side brick return flues and a single exterior flue taking gases under the base of the boiler to a tall chimney, result in a pretty big model – by my calculations it would have been huge. I obviously decided this was completely impractical, so took inspiration from the 'Sweet Pea' style marine boiler and designed it so it could appear as a Cornish boiler and stay within model proportions, suitable for a 1' x 2' bore and stroke engine. My intention is to build the Stuart Victoria next.

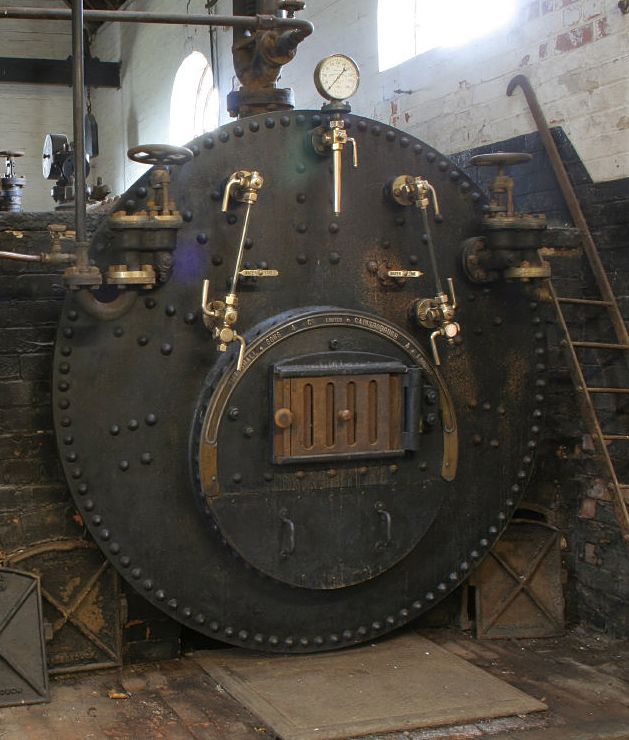

The back head is pretty key to giving a sense of authenticity so I did try to model this on a real boiler. (See pictures) You will see that my solution was to put a 3.75 inch diameter firebox inside a 6 inch barrel. The firebox is around 5 inches long and is secured into the back head with silver solder and a riveted staying ring, which accommodates the back head and grate assembly. The back head was machined from a 4" diameter x 1" thick piece of cast iron solid.

There are 16 smoke tubes and the whole boiler is 15 inches long which allows for a 2.5 inch deep smoke box which accommodates a 'steam dryer'. There is a steam blower built into the chimney base, fed from the stem dome.

From the design MSWP is 80psi, so the initial hydraulic test was 160psi for 30 minutes. The boiler is silver soldered throughout – by me. All bushes and the domes are bronze. All materials were sourced from Blackgates, and the cheat was I used pre flanged 5" Springbok smokebox tube plates and the firebox tube plate was supplied flanged. My design and initial drawings were run through a computer model by my boiler inspector. I also own a 4" Scale TE.

The grate is Blackgates 5" gauge stainless section, which I formed to create a basket 3.5" x 4.75" x 1" deep. I have test steamed it on anthracite grains and it steams reasonably well. Well very well once I got the hang of it. If you look at the nearly finished image, you will see the ash from today's steaming.

I bought a 6" Southworth steam pump off a chap in Stamford and made the Stuart hand pump from castings to supply feed water.

Anyway, I can expand in more detail if anyone is interested.

Edited By Driver 92212 on 20/11/2014 20:08:50

Edited By Driver 92212 on 20/11/2014 20:11:47

Johan van der Werf.