Next post with simulated brevity…

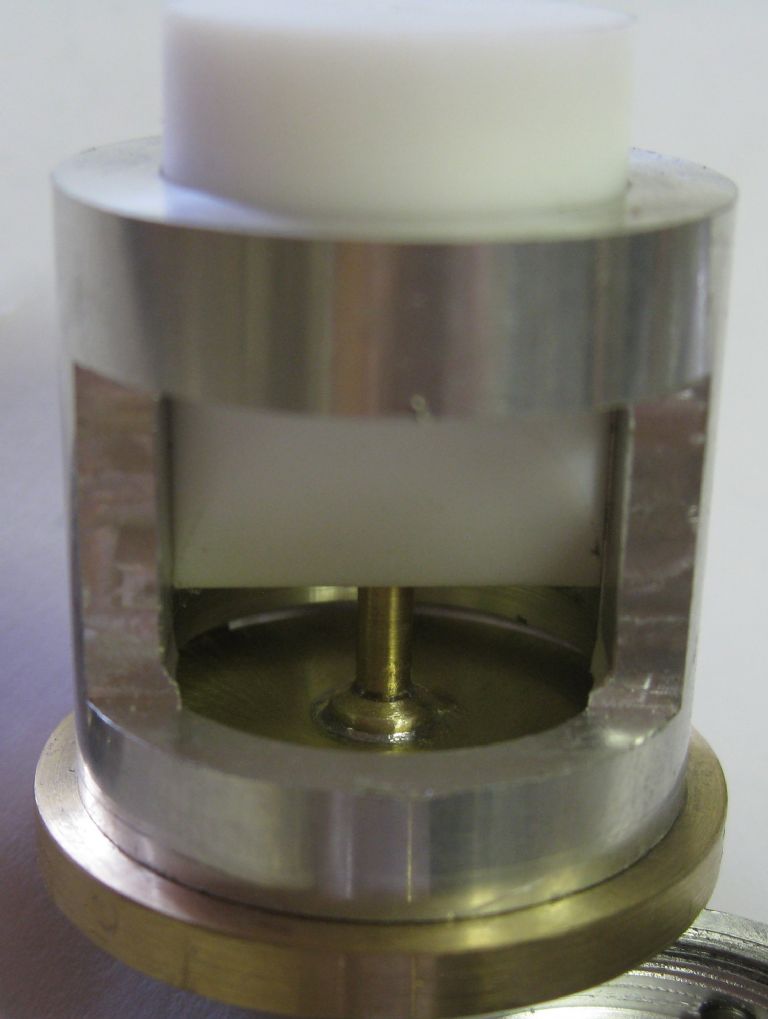

The coolant pump is also done and tested.

In a previous post I indicated I would use a neat oil 'coolant'/lubricant – That was not a success. The oil was great, very thin, and does is intended job well, but the mess is intolerable. An oil film sits on everything, and just sits there. It does not run off like the water soluble oil solutions do. It sits on the swarf and takes days to drain of, and even then , not so well. So I dug for a more modern soluble and found some excellent stuff – Ecocool 600-NBF, made by Fuchs. from 4:1 to 20:1 mix, and £45.00 for 20liters. When mixed, the solution is clear and has no detectable smell. Drains off quickly, and left pooled on a shiny machined clean mild steel plate over the Christmas/New year week, left not a mark.

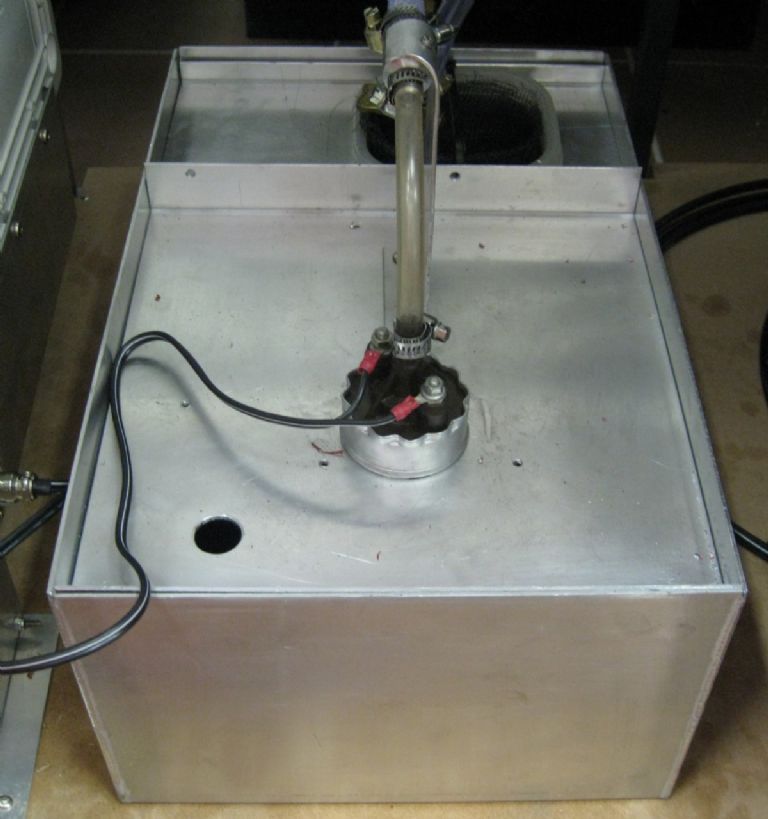

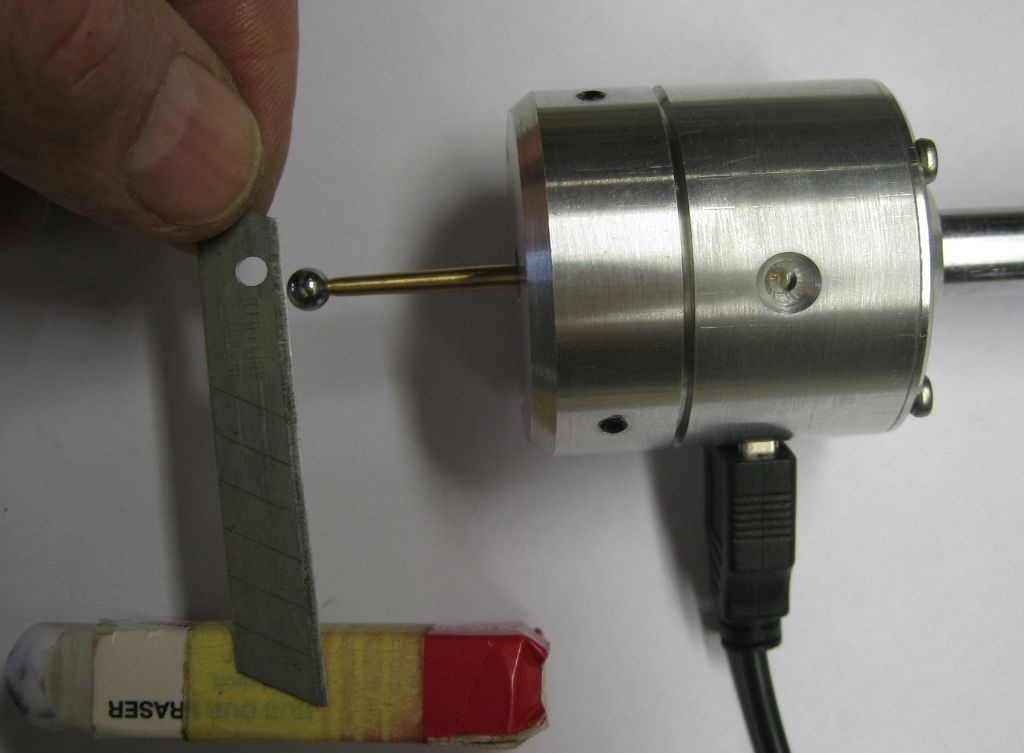

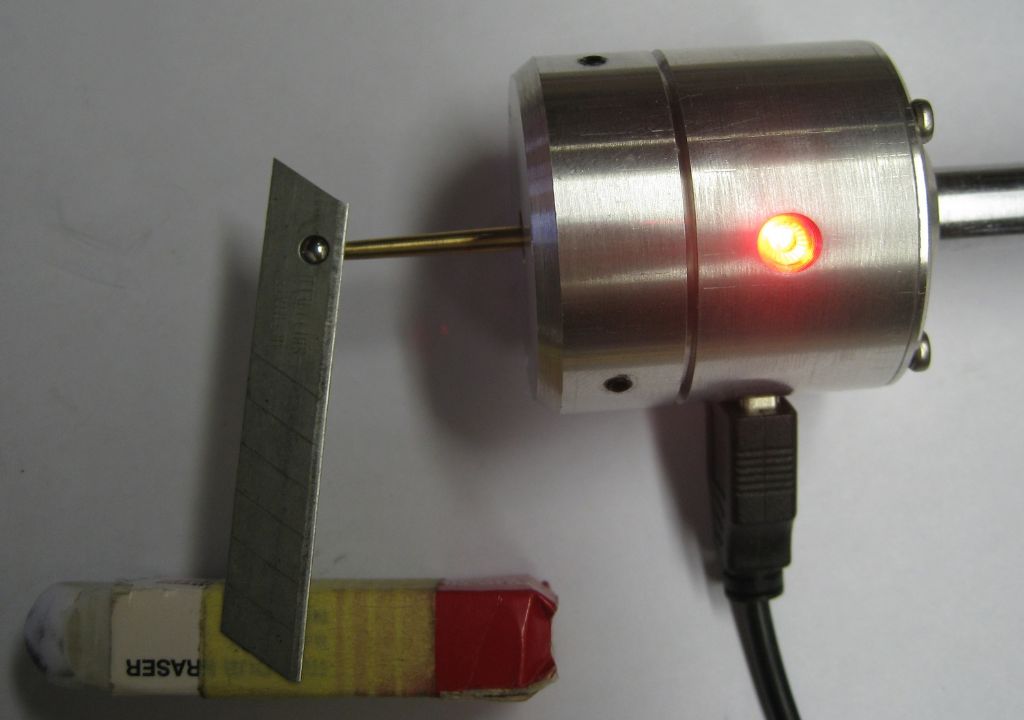

The pumps is a 12V fuel injection pump – seems to be able to develop a good few bar pressure. It hangs in the coolant tank with an inlet sieve. The drain from the lathe goes through 2 further sieves on route before the coolant drops into the tank. We will see what the coolant mix does to the pumps gears/seals, etc. The pumps was inexpensive anyway!

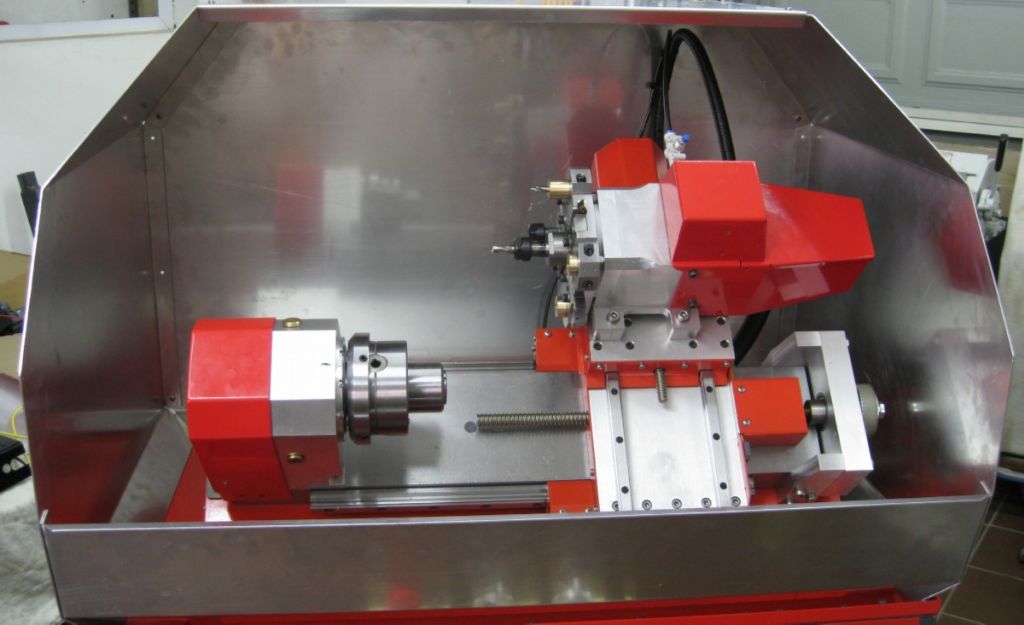

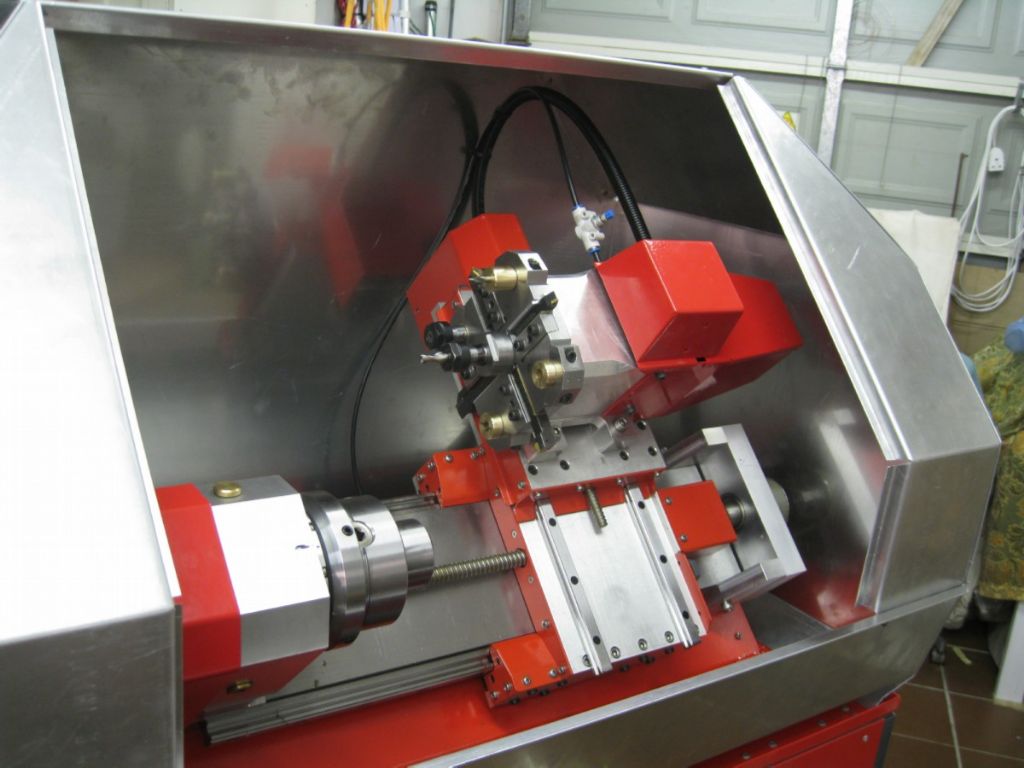

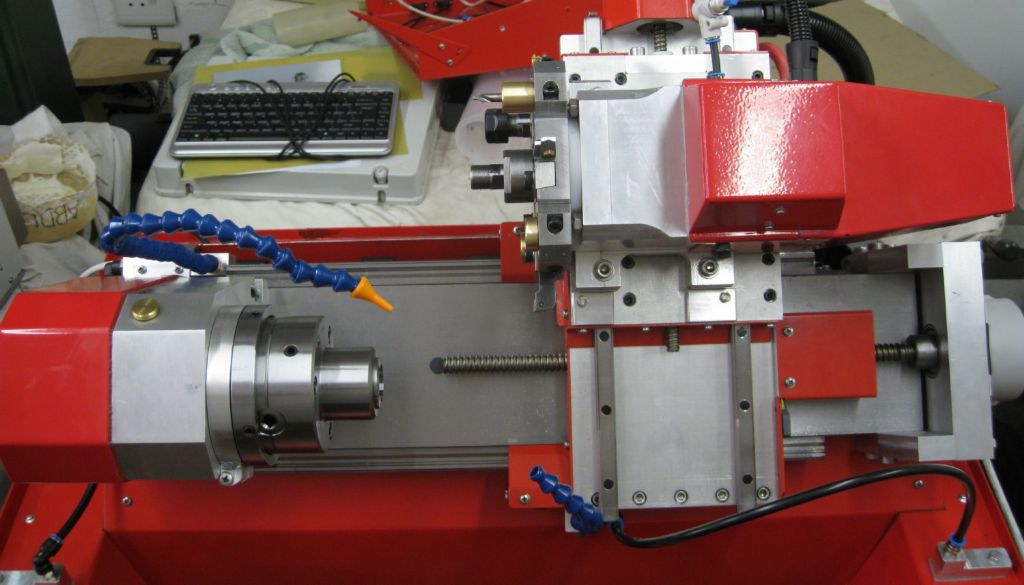

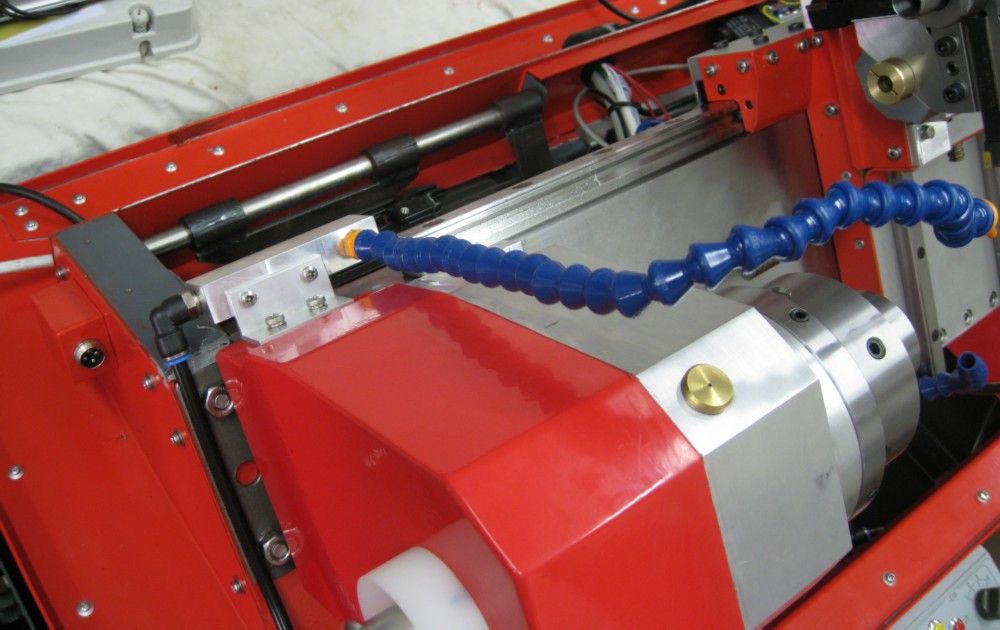

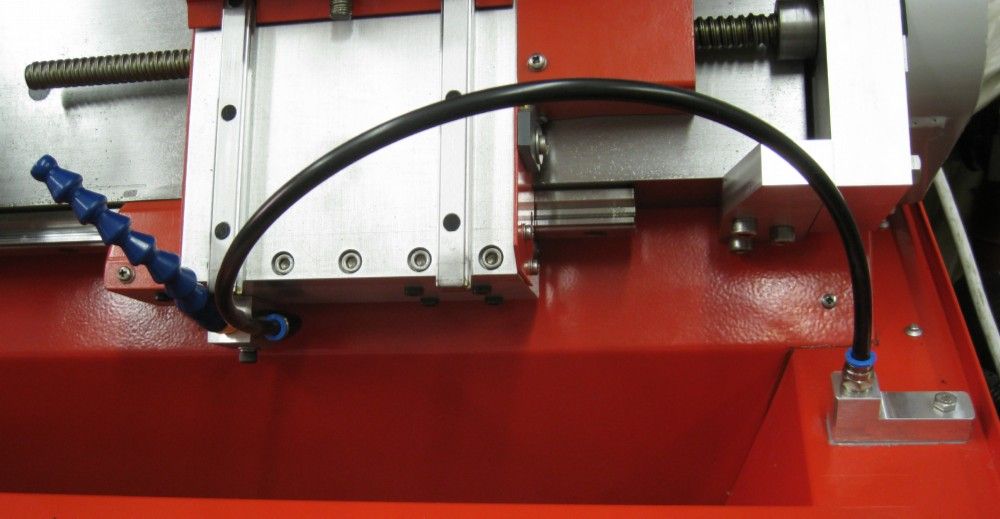

Coolant spouts placement on a CNC lathe is a big deal..Normally on the CNC machines the coolant spouts from the tool holder onto the cutting edge, often out the cutter itself with special coolant channels in the cutters, drills, and tool changer. Since that is not possible on my setup, I opted for two spouts, one placed for surface and face cutting, and one for drilling and boring and with Live Tool spindle- the latter spout to the right of the workpiece, the former on the left.

(some suppliers are STILL on holiday, so the right spout locline has not yet been lengthened..)

The left spout is fixed, and will flood fully the workpiece from behind / under. The right spout moves with the carriage and is aimed at the workpiece center face.

Still some machine covers at powder coaters, and when that's done the machine is 'ready' to use…

On the software side, My good Wife has modified much about Linuxcnc's basic setup to make a really nice user interface, and with features that make the machine user friendly. I looked at the many 'available' screen MMI options out there for Linuxcnc – some very fancy looking ones, and after detailed investigation decided they are of little use. They tend to be flashy, many buttons and LEDs and options, dozens and dozens..There are 'nice' tools to allow the screens to be easily modified and changed, but likewise, I found that it took days to understand what the creator of that screen had done, what the buttons did, how they tied into Linuxcnc, etc, After writing up a spec of what I wanted on a display, info, buttons, etc, it was clear that these screens were a waste of time they were so much eye-candy, done because the creator could…I bet none of those creators actually ever used one of there creations in a working machine environment!

In addition, there are wonderful incompatibilities between the screens ( the language they are written in, Python2) and Linuxcnc Vers2.9, which ONLY works with Python3 addons, etc. Lcnc vers 2.8 is the current 'formal' release, but does not have any of the kinematics and features I need for the C axis / live tool on my lathe.

So, My good wife modified the vanilla Linuxcnc AXIS screen definition, down at Python3 level, and we have a very nice screen setup… As soon as the powder coated stuff is back, lathe assembled, etc, videos will happen!

On the CAM side, I found a package called KIPWARE :

Kipware CAM sofware

Which is a conversational CAM tool, works very well, can do my Live tool / C axis with little effort, and allows easy Gcode generation for all basic lathe machining operations. The Company is 'glitzy' and sort of sticks in my throat, the product presentation is also a little garish, but it works and the price is not bad..

That's it for now.

sam sokolik.