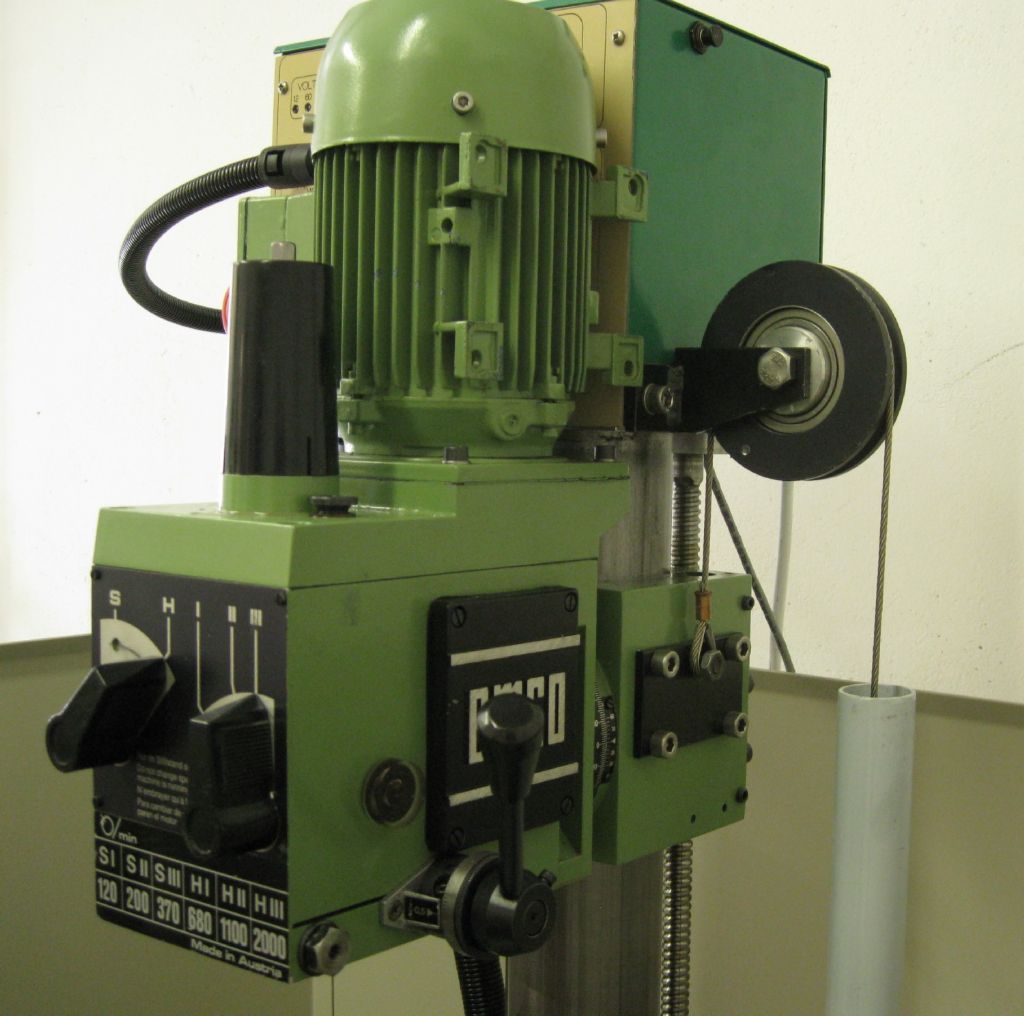

About 16 years ago I converted my EMCO FB2 to CNC , using MACH2 and a parallel port equipped windows PC – XP then..

XP is no longer viable, and nor are PC's with parallel ports..I still have 2, one running Windows 2000 (!) and one XP, both run MACH2 fine and are used for my CNC router table, but both have 'issues'…

I used The XP PC for the FB2 as well. Since I have another side project – the small CNC Lathe, controlled with Linuxcnc and MESA I/O cards, I though to convert the mill to Linuxcnc as well. However, after the many hoops I jumped through to get the lathe doing small things, I decided to stick with MACH2 and purchased an ethernet controller for the machine.

This proved to be painless, installed very easily, interfaced to MACH2 and comes with the designers Software that is very similar to MACH2 and also works very well.

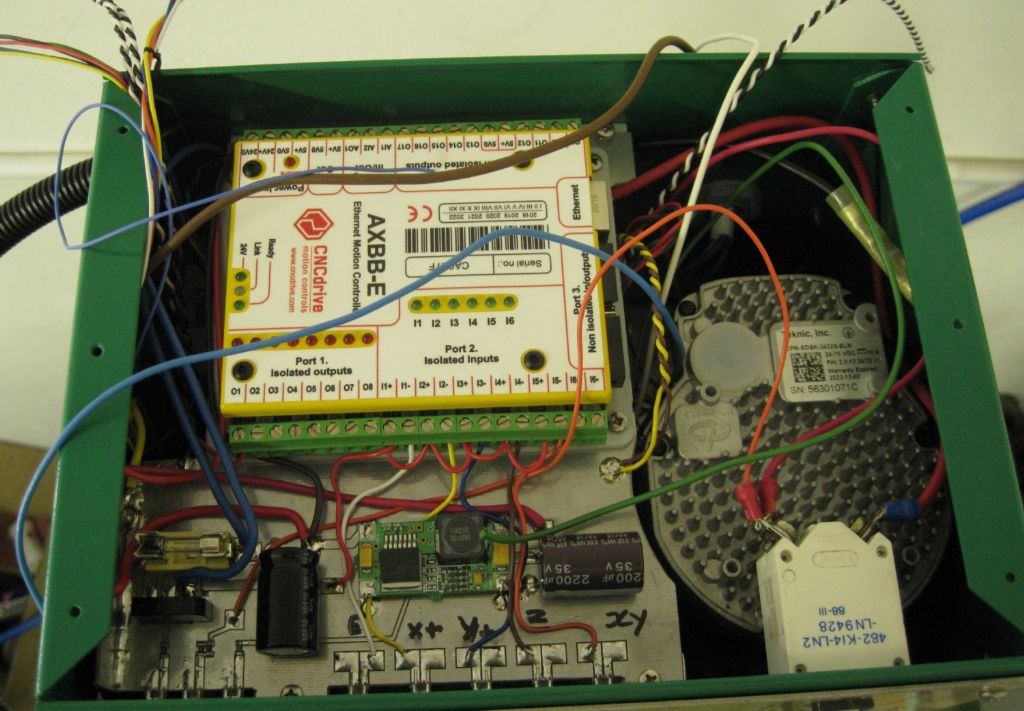

The Module I settled on is the AXBB-E ( E for ethernet from CNCDrive.com) and it provides a lot o built-in buffered I/O, some isolated discretes, Pot inputs for spindle speed and axis feed override, analogue outputs for VFD spindle speed control, etc.

**LINK**

The manuals are quite decent, and installation was very smooth.

So far it performs as advertised and I am happy..

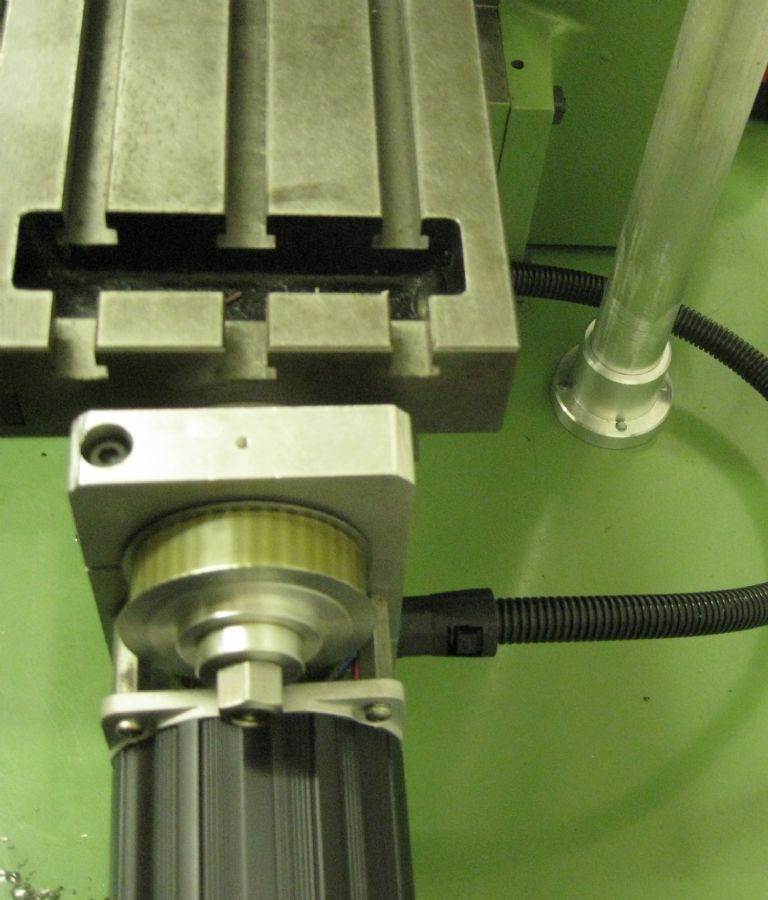

While doing the upgrade, I also changed the steppers to Clearpath closed loop steppers – the steppers I had on the machine were STEBBON, a British make, and a flop, I fear…The business end bearing OD was about 0.6mm less than the ( very roughly) machine cavity in the motor bell-end, and the bearing was 'glued' in – two of the motors bearings shifted slightly, and the rotors would sieze against the stator…

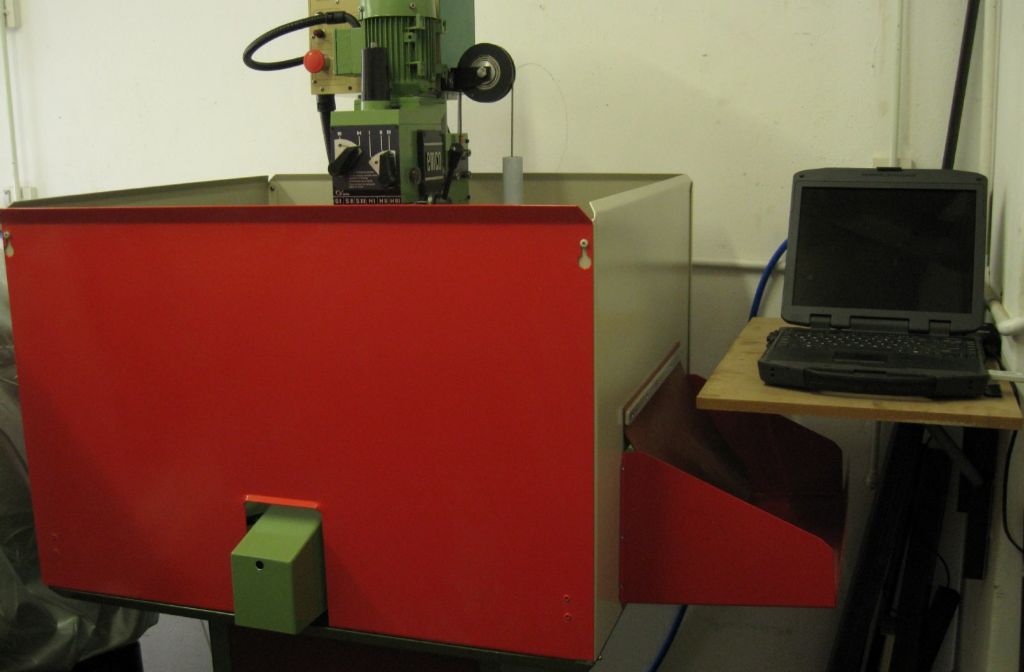

I also made 'heavy duty' swarf covers for the machine as it has to do a lot of EN1 and EN3 machining on my CNC lathe projects, and It will do so under full pressurised coolant flow – more to keep swarf out of the cutting edges..

And lastly, I added a counterweight for the head – Head is 22kg sans tooling, so I added a 19kg counterweight – which works very nicely!

The AXBB card in the control head

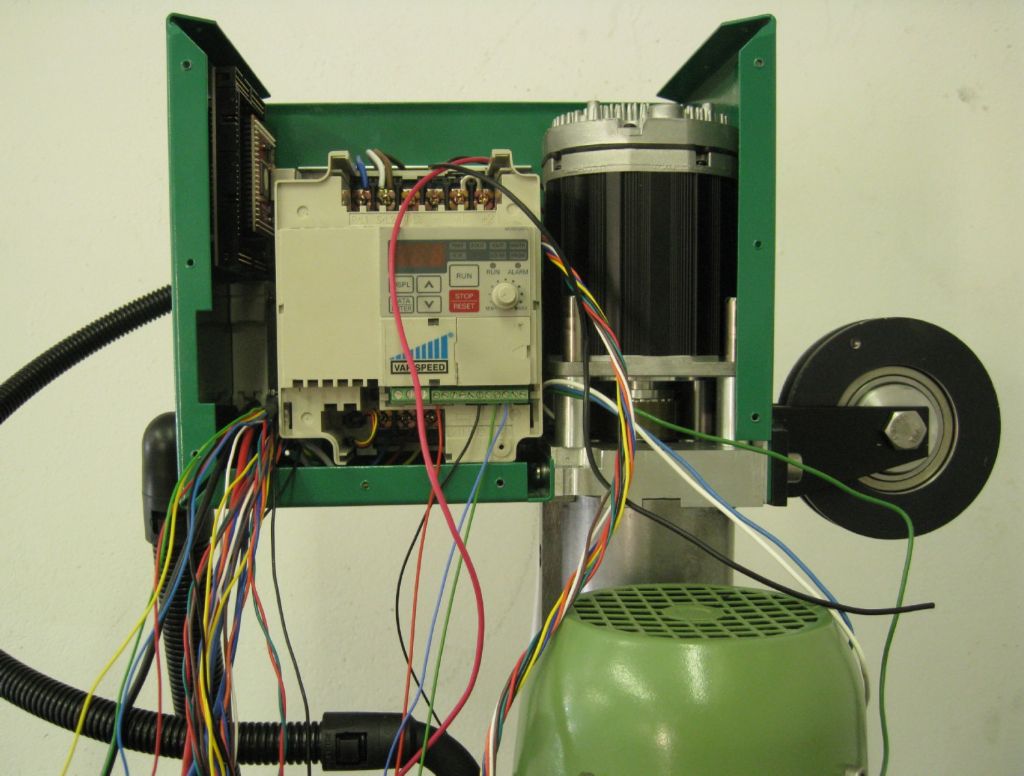

Wiring….

All wired..

Counterweight Pully

Counterweight below the swarf tray.

The X axis Clearpath servo

Swarfguards in place

Front flip away swarf guard in place

Now to find a powerful suds pumps..

Joe

Edited By Joseph Noci 1 on 06/06/2021 17:30:08

Joseph Noci 1.