Hello Everyone,

I wonder if someone could advise me as the best way to do the following?

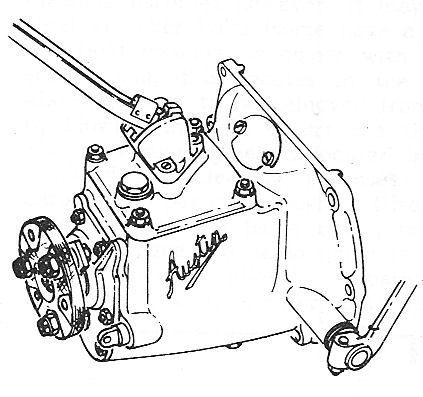

I'm making a clutch pedal for an Austin Seven. Before we start, let me say, I do realise the easy way is to buy one from an autojumble or the 'usual suspects', but Seven addicts will appreciate that while the Ruby type pedal that secures with a pinch-bolt are two-a-penny, the earlier cotter-pin secured variety are much rarer hence my approach.

For machining simplicity, I elected to make the pedal in four pieces. A boss to fit the spindle where it emeges from the gearbox; the lever, the pedal stalk and the foot-pad. I've cut a boss 35 x 35 x 40mm from mild steel, radiused the corners for appearance and drilled a hole (about 15mm diameter) to slip over the spindle, plus a cross hole for the cotter pin.

The difficulty is there's a round section (collar if you like, about 20mm O/D) on the gearbox side of the boss. This takes the return spring – the coil fits over the round part and one end passes around the lever and the tail locates in a small hole in the gearbox casing.

How can I best make the round section on the boss? I've thought of holding the rectangular piece in a four jaw chuck on the lathe and doing an interupted cut; I thought, perhaps setting it up on a rotary table and rotating the block against an end mill, but I don't have a four jaw chuck for my rotary table; or perhaps shaping it on a belt sander?

As always, expert guidance would be very much appreciated.

Best, as always from snowy Paris! Martyn

Howard Lewis.