Posted by William Ayerst on 31/10/2020 09:02:50:

…

I guess if I can find 3/8" tools they should in theory be bang on?

…

No, shimming is almost always necessary.

The essential requirement of a shank is it puts the cutting edge near level with the lathe's spinning axis. Even slightly high is bad because the tool rubs. Too low is tolerable but most tools cut best positioned a little below the centre point. Tool points have to be adjustable. Shimming is the easy way of adjusting height. I use aluminium strip, cut up can metal, metal binding tape, and mild steel milled to height. Almost any metal will do. Easy but potentially time-consuming, so there are alternatives,

Shank size may not matter much provided the cutting edge can be put on target. Avoid oversized shanks because they either won't fit the tool-post and/or need a lot of grinding down: far more practical to use smaller shanks and shim them up to height.

Full sized shanks (3/8" on the ML7) are stiff and strong, but it's often advantageous to use smaller shanks for fine work or cutting in tight spaces. My lathe takes 12mm tools, but I prefer 10mm, use 8mm a fair bit, and 6mm on special occasions. Decided by the job – I don't use 12mm on small diameters and I don't use 6mm tools to rough out big lumps of steel. 8mm would be a good general-purpose size for a ML7.

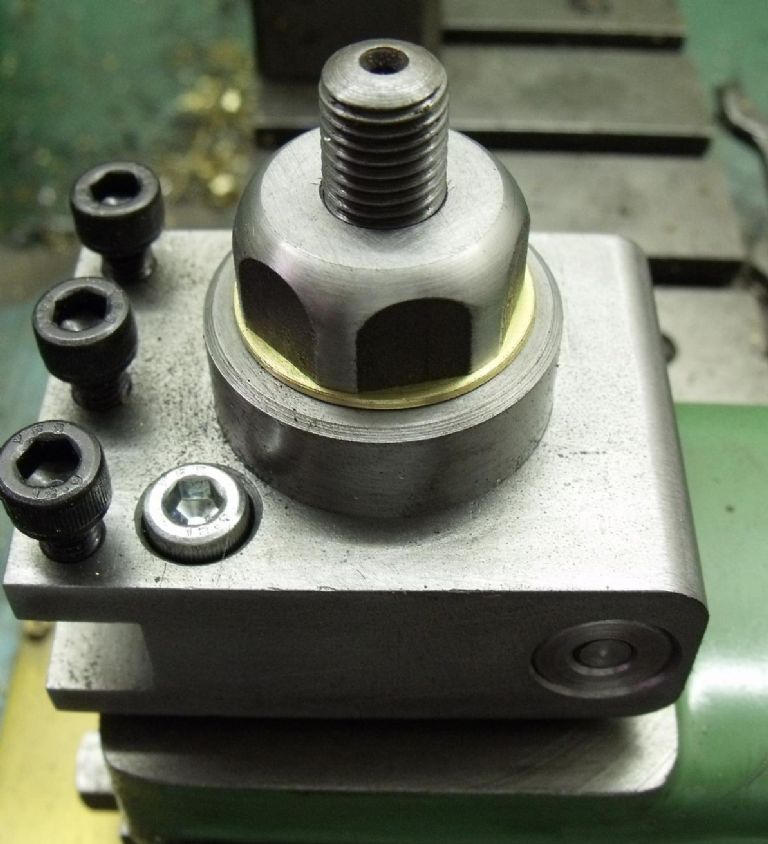

Not used one myself, but boat type adjustable height holders are widely despised because they're fiddly and prone to move. Pretty much obsolete. Far more successful are the quick change types where the tool is held in an adjustable plug-in cartridge. Easy to set the tool height, the cartridge is solid, and no further adjustment is needed until the tool is resharpened.

A disadvantage of HSS is tool height is altered by sharpening, making re-shimming and readjustment necessary. It's all part of the game.

Setting tools to height isn't difficult, but it takes time. Industry favour carbide inserts, which are swapped out rather than sharpened – really quick with auto-tool changers. QCTP are probably the fastest way of swapping HSS tools, but I find a 4-way tool-post with pre-shimmed carbide insert tools fast enough for my purposes. Basically, once the tool-height needed by a particular set of insert holders is identified, the necessary shims can be ready to hand, glued together if the fancy takes me.

A huge amount depends on what the lathe is used for. Previous owners of William's ML7 didn't bother to hange the basic fitting it came with. Presumably the lathe was worked slowly with a limited range of tools. This might be fine for William too. Others have to work quickly on jobs requiring multiple tool-changes, or perhaps work best when they don't have their flow interrupted by fiddly tool-changing. For them a QTCP is best choice. In the middle is the 4-way tool-post. Up to 4 tools pre-mounted, with moderately fast tool changing provided the tools are pre-shimmed.

If I were William I wouldn't rush to change the holder. It will cut metal as well as any other! After the lathe has been used for a few projects it will be obvious to William if the holder needs to be changed or not. Could be the money is better spent on something else, and that list is endless…

Dave

Edited By SillyOldDuffer on 31/10/2020 10:42:05

John Baron.

six tools are available very quickly. Changing over for screwcutting or knurling is slower, but not being on piecework, time is rarely of the essence..

six tools are available very quickly. Changing over for screwcutting or knurling is slower, but not being on piecework, time is rarely of the essence..