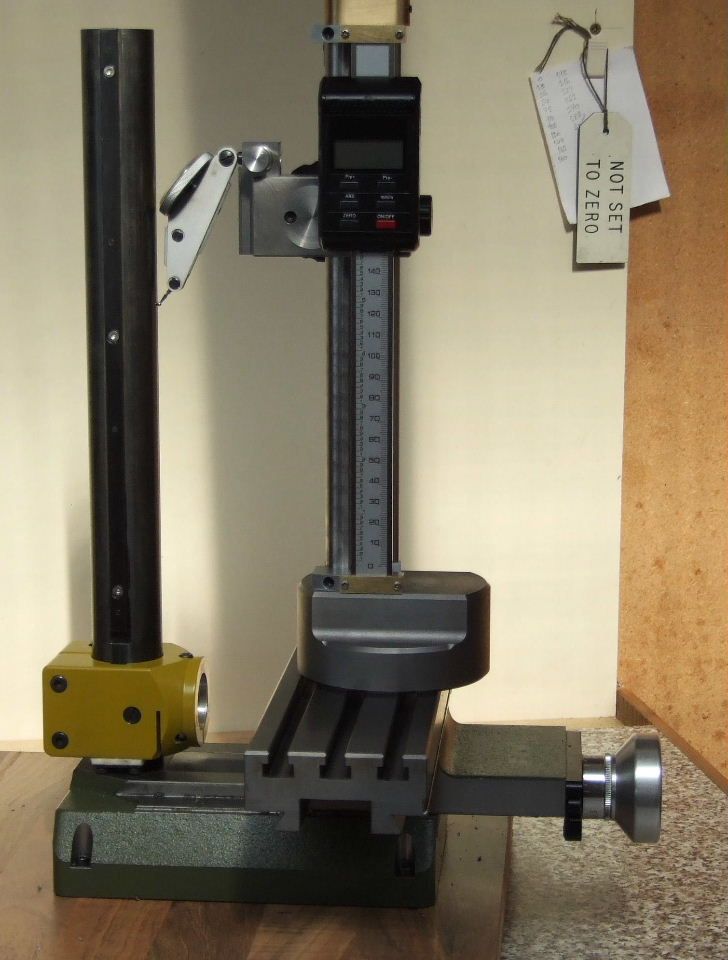

I have finally managed to finish the Multipurpose Clock stand. The clock fitted in the above photograph reads 0.002 mm and was a given to me by a friend. When using this in my Starrett Scribing Block I could seldom get the same reading twice. The weight, stability and improved locking mechanism on the above clock stand has made it all worth the effort. The clock now gives the same reading time after time.

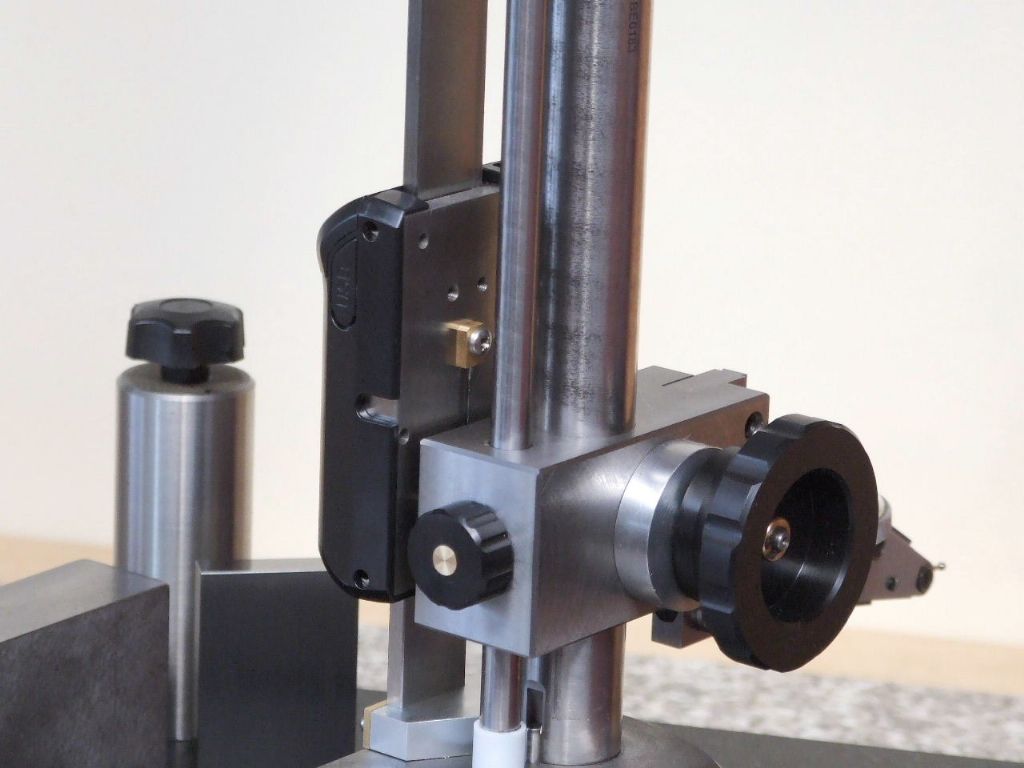

This next photograph shows the Slider to Read-out connection. I am indebted to John Slater for this suggestion. It is piece of Pinion Wire and allows the two units to move laterally independent of each other. I am also indebted to Ketan for supplying the DRO after an enquiry for a drawing. As I have stated previously this was only added as an after thought on my part. The mounts for which are dead easy to make.

This shot also shows Locking Knob which works on a separate shaft and thus does not influence the clocks setting. The Locking pad is spring loaded which always ensures a constant pressure on the rear face of the Column by the Slider.

This shot shows the Handwheel in the inboard position which gives a direct, or rapid traverse.

Pulling the Handwheel out engages a reduction drive of 4:1 for slow traverse and clock or DRO setting. The traverse is taken care of by an MXL toothed belt sunk into the Column. There is a tensioning adjustment incorporated in the top belt anchorage.The belt being sunk into the column ensures the teeth are always kept clean. The drive I was expecting to be a little Notchy but in the end my worries were unfounded.

This check was to verify the perpendicularity of my work. Running the DTI up the side of my homemade Cylinder Square and then turning the Cylinder through 180 degrees showed no error. Which was very satisfying.

The DTI can be mounted in the Vertical and used to check heights of components. Both as a comparator or in conjunction with the DRO.

This shows the scriber fitted for use as a digital Height Gauge. It takes literally seconds to change from one to the other. The scriber proper is a separate piece bolted to the end of the holder.

Finally checking the perpendicularity of the Proxxon Milling machine Column. While the clock position is not ideal and no reading at such an angle could be trusted. Using the clock in conjunction with the feedscrew does give a quantifiable reading. Which in this case was a lean backwards of 0.03 mm over 150 mm plus of vertical travel.

Given the weight of the milling head this will probably rectify this error.

I hope you have enjoyed this little device.

Regards

Gray,

Graham Meek.