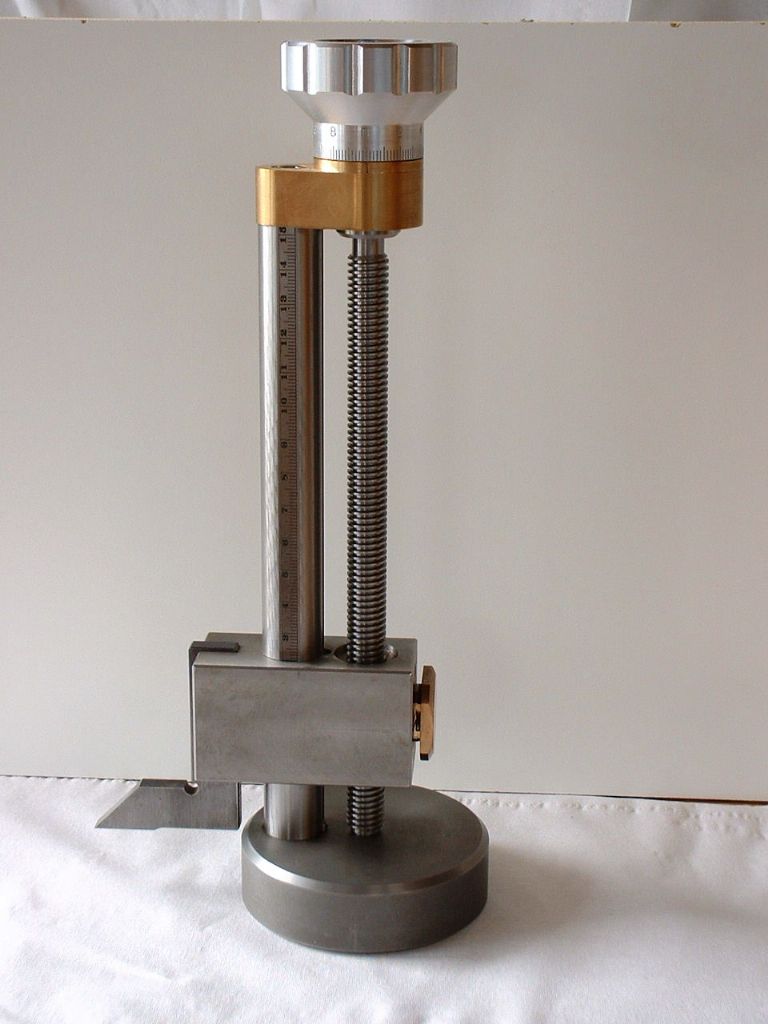

Yesterday was spent checking the Column out. I first turned a "Cup" shaped bush to fit the top of the Column which removes the need to avoid the two key slots in the Column. As this was turned on the O/D and bored at one setting concentricity should be assured. The "Fit" on the Column was very close but I was still able to rotate the bush on the Column.

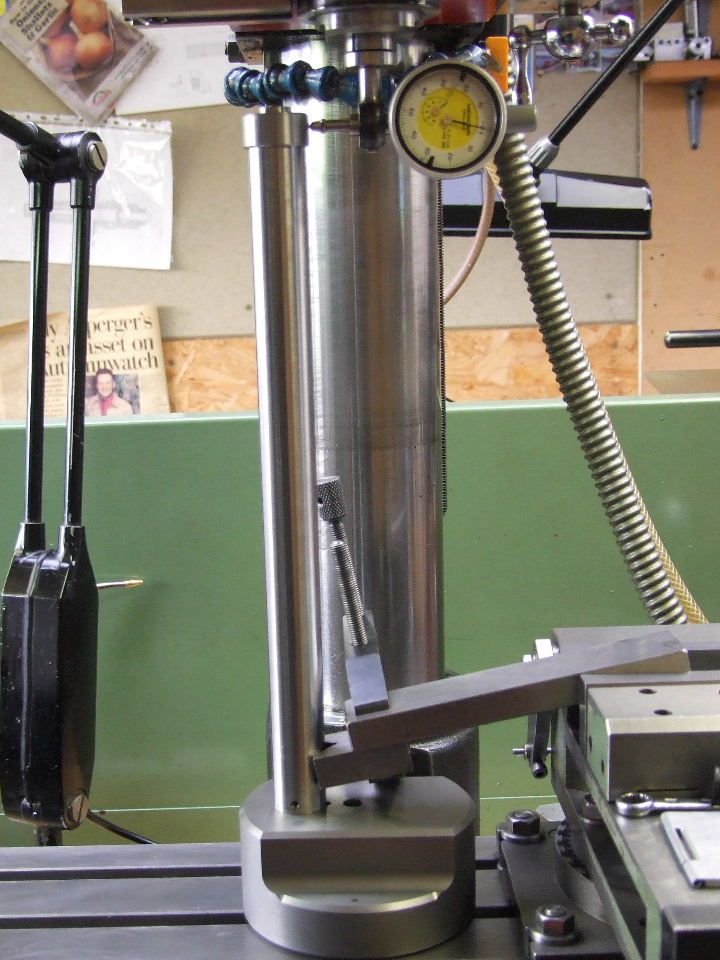

The Vee block attached to the parallel in the vice machine is purposely angled down in order to present two knife edges to the Column. This ensures only point contact and that any out of squareness in the Column is not masked by a full on Vee block face.

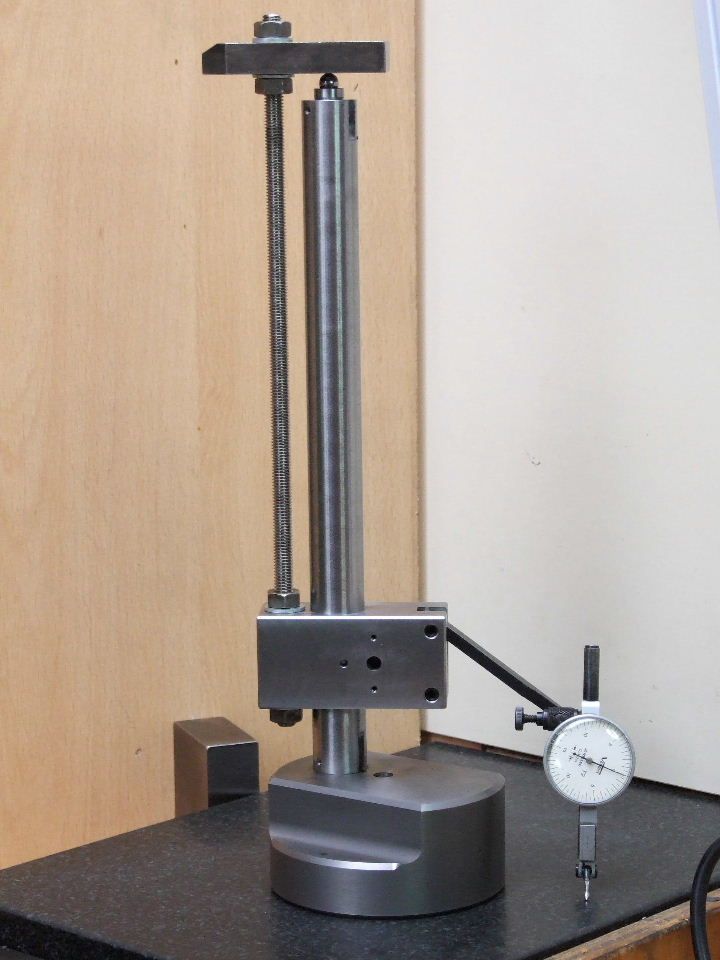

Once the set-up was ready the assembly was placed against the Vee block and the DTI brought into contact. Traversing the Y-Axis the null point was found which meant the DTI was on the Column centreline, (this procedure is repeated as the Column approaches perpendicular, to remove any further sources of error).

At this point the Bush was also rotated on the Column to see if there were any errors in the machining, which there weren't. It always pays to check.

The contact face for the Column is a spot face done by mounting the part on the faceplate.

The initial out of squareness was 0.1 mm in the Y-Axis in the above photographs and 0.05 mm in the X-Axis. Using my Pull Scraper and removing barely 0.005 mm from the surface of the spot face opposite the maximum errors had the Column, virtually perfect.

The maximum error in the X-Axis was 0.005 mm leaning towards the centre of the Base Plate. In the Y-Axis the there was no discernable error. Turning the Column in the Base Plate by 180 degrees gave exactly the same results. Which is what I would expect as I already checked the Columns straightness using two Vee blocks and a Clock on the surface plate.

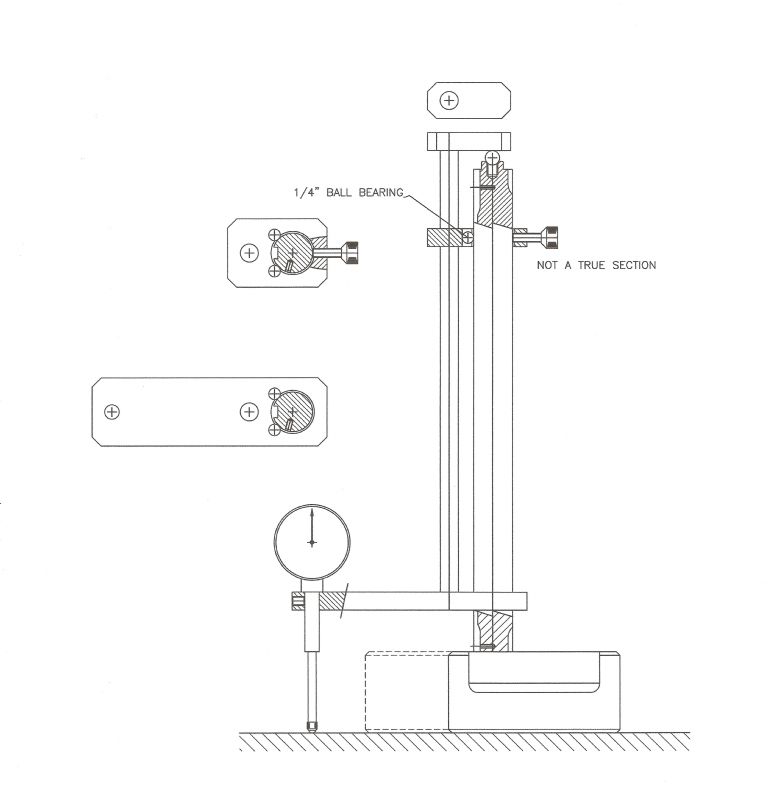

To double check I might just make the tool shown above, but not until the Clock Stand is complete.

Regards

Gray,

Graham Meek.