Happy New Year,

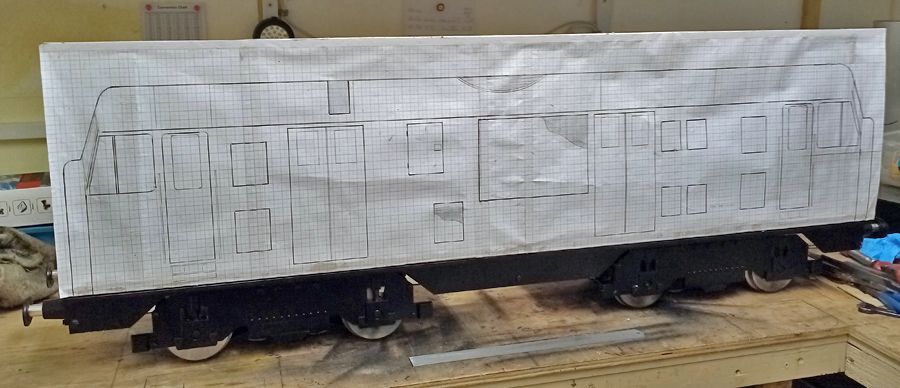

Just seen your build thread, looking good.

I have been in joinery manufacture for about 40 years, and had my own business for about 30 years, so this is my opinion on MDF etc.

MDF is available in standard, moisture resistant, exterior and fire resistant grades.

There is no noticeable difference in density in any of these grades. The moisture resistant, (mr), grade is always dyed green, either right through, or just the core for identification purposes. The standard and mr version soon swell and disintegrate if they get wet for any prolonged time. The more expensive exterior grade also requires all edges to be sealed if it is to survive prolonged exposure to water. There is a new kid on the block, which is described as extremely durable, and sold as Tricoya, not cheap but with a claimed durability, guaranteed for 50 years.

I have only ever seen HDF sold in 3mm thick sheets with a white/black or cream coloured finish on one face, it is used as a replacement for white faced hardboard. The denser deep rout MDF is, I think, only available in thicker boards. It is used because the “normal” thicker MDF boards can have an inner core made up of larger fibres, which don't leave a good finish when routered into.

All MDF is abrasive and blunts hand tools and HSS type spindle moulder tooling very quickly, TCT or even diamond coated tooling is required. TCT router cutters are ok to use, but do blunt quicker than when used on timber.

Thin Birch plywood is nice to use, but I think it is interior grade only, in thin sheets, and not moisture resistant or exterior grade.

Lawcris, Arnold Laver, Timbmet and Lathams are all good suppliers of MDF and Ply, depending where you live.

Solvent based contact adhesive is still available, not seen the really small tins or tubes for years, I think shops stopped selling them during the glue sniffing era in the 80's.

I have been using this solvent based, Link , own brand from, “Construction Chemicals”, the big name EVO-STICK is also available, but I am not convinced it is the same formulation as it used to be. It all goes off in the tin after its been opened, but sometimes it's still ok after a year or so! Water based is also available, but I haven't tried it. The red plastic spreaders are also a thing of the past.

Polyurethane glues, such as Gorilla glue, stick well, they don't care about a freezing cold workshop, (unlike PVA types), and are waterproof, but also messy, and possibly carcinogenic, via prolonged skin contact.

Hope some of this may be of interest. I am in East Yorkshire, if I can help by ordering anything for you, or cutting anything.

Mark.

Edited By Mark Easingwood on 05/01/2020 17:53:38

Ron Laden.