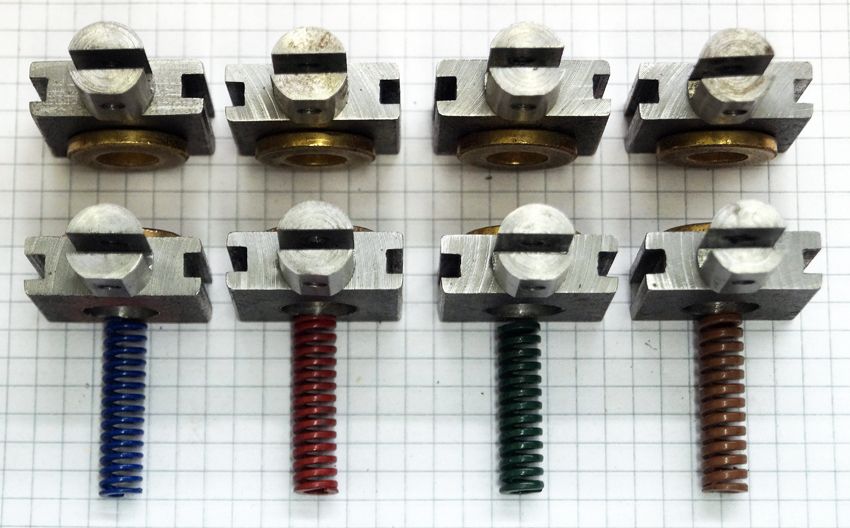

Hi Ron, Why two greased steel shims? just based on experience and some basic tribology theory.

If you had one shim between a rotating pulley hub and a stationary Oilite bushing, in theory if there is side pressure on the shim the shim will rub on the Oilite or the pulley or both, a high wear situation.

If there are two greased shims, in theory one shim may stall on the Oilite or rotate slowly, the other shim may stall on the pulley or rotate slowly, but the main relative rotation will occur between the two greased shims. The grease separates the shims and minimizes the wear and the shims being hard and relatively flat and smooth steel will have low friction coefficient to begin with. This usually will result in low or no wear on pulley or Oilite. It's not a tragedy if after many hours you have to replace the shims for 50 cents or a dollar. You have saved many tens of dollars replacing shims rather than a chewed up pulley and Oilite bush.

Again for occasional use the above theory may not matter much but just offering food for thought based on working on a LOT of machinery over the years, seeing what works best.

All ready to be shot down in flames now by the usual armchair experts!

Ron Laden.