Class 22 Diesel (next project)

Class 22 Diesel (next project)

Home › Forums › Locomotives › Class 22 Diesel (next project)

- This topic has 239 replies, 30 voices, and was last updated 18 October 2021 at 16:21 by

Ron Laden.

-

AuthorPosts

-

9 May 2019 at 10:37 #408370

Joseph Noci 1

Participant@josephnoci1Posted by Jon Lawes on 14/08/2018 09:05:58:Just thinking outside the box, what about using brushless motors and lipo batteries? There are a lot of good speed controllers in the model car world, places like HobbyKing have a huge variety. I used one in my boat that worked out as almost 4hp powered by two 6S lipo batteries, good battery life and power. Only downside was the motor and speed controller both needed water cooling (which I achieved using a small pump).

The typical brushless motors used on aircraft etc are not very good in this application Jon. They tend to have very little starting torque and if they do not get going, the controller and motor end up out of sync and the motor stalls. Some of the RC cars/buggies use sensored brushless motors for this very reason – to get low speed control and good launch without stalling or wheelspin. Problem is that the sensored motors are much more costly, and are not easily available in larger sizes. However, prudent choice of motor kv rating (RPM per Volt), motor size and gearing between motor and drive mechanisim may give a good result. We built a 'sand-buggy' – a one man go-kart, using a 80kv, 5KW outrunner, fed with 80volts. Tyres on the kart are 300mm diameter pneumatics ( from wheelbarrows..) . The kart reached speeds of 100km/h ( OHS…Don't ask..) and we could spin the tyres on tarmac. We could cruise at 20km/h for 1 hour with battery pack of 86volts/40A/H.

In the quest for the fastest 1/4 mile time, we blew the motor up at around 13KW input..

Joe

9 May 2019 at 11:11 #408383duncan webster 1

Participant@duncanwebster1Axle hung motors have the great advantage that the distance between axle and motor doesn't change with suspension travel and so you don't have to worry about gear meshing, belt tightness etc.

Having watched your rate of progress on the first loco, I expect to see this one running before the end of the year.

9 May 2019 at 14:05 #408426Ron Laden

Participant@ronladen17547Hi Duncan

It is probably not clear from my sketch but the motors on this version of the bogie are not axle mounted they are fixed to the side plate. I am hoping that the belt tension will be ok, my maths and geometry is not up to it so I resorted to using a pair of dividers to check the upper and lower belt length against the axle travel. As far as I could see the dimensions cancelled each other out but I could be wrong of course. Should any of you clever chaps want to check, the motor pulley is 14.6mm dia and the axle pulley 68.75mm dia. The pulley centres are 73.0mm and the vertical travel of the axle is 6.0mm max. As per the sketch the axle is at its lowest point sitting on the horizontal centre line with the 6.0mm of travel being upwards.

Ron

15 May 2019 at 08:47 #409313Ron Laden

Participant@ronladen17547The motors I have decided on have arrived, they are Chinese and available from UK electric scooter suppliers. It was a no brainer really, a set of 4 motors for quite a bit less than the cost of a single UK manufactured motor of equivalent spec. They are listed as 24 volt, 150 watt, 6.25 amp with a no load speed of 2750 rpm and come fitted with a 3mm – 16T belt pulley. They have twin ball races and having taken one apart look to be well made.

There is a question mark over the quoted figures though and I had a "technical conversation" with the supplier. He said: great motor, loads of power. Me: is the 150 watts input or output..? Him: silence, then "input" Me: it would have been better if the 150 watts was output. Him, silence again then, erm, no it must be output, loads of power……LOL

Anyway I read all the user reviews I could find and they all said the motor gives good power and is reliable. One guy thought the 150 watts was about right, based on what though I dont know. Another said probably a bit lower at 100-125. One guy uses one to power a watch makers lathe and he thought at least 150 watts but without proper testing who knows..?

Not knowing the actual figures leads to a bit of guesstimation and gut feeling when making calculations, gear ratio,s for instance. The quoted no load speed is 2750 but the motors I have are within 150 rpm of each other (which is good) averaging out at 4050 rpm.

Now 4050 rpm is quite a bit faster than 2750 so I have estimated a loaded speed and geared at 4.25/1 to achieve a loco speed of 6mph. Will have to see how it comes out in the wash but should I need to change the ratio I can easily change the motor pulley size up or down, hopefully I wont need to.

I was also thinking that one of these motors could be a good candidate for building a power drive for the mill table, doubt I will ever get around to it though.

Ron

Edited By Ron Laden on 15/05/2019 08:50:37

15 May 2019 at 10:39 #409330SillyOldDuffer

Moderator@sillyolddufferBatteries, automotive, leisure, and deep cycle differ in their internal construction. They all have the same construction, but:

- car batteries are heavily optimised to deliver the short bursts of of high current needed to start an engine, and then to recharge as quickly as possible. They don't like being emptied. They are quickly spoiled when used to deliver ordinary current and/or trickle charged. They work, but have a short service life. Mass sales make them relatively cheap.

- Leisure batteries are designed to charge and discharge at more normal rates whilst providing a sensible service life. Not ideal to empty them, so good on boats/caravans etc where they can be used overnight, and then recharged during the day. They they tend to be pricey because their construction is more expensive than that of a car battery and the market isn't as competitive as that for car batteries. Will last a lot longer on a loco than a car-battery but not the best.

- Deep cycle batteries are like a leisure battery, but have been further optimised for deep discharge. The construction is like that of a super-leisure battery, ie more expensive.

Best battery depends on the purpose. You could borrow your car's battery to briefly test a loco was working without damaging it. An expensive mistake to use the same battery for a few hours on a track. Pricey deep cycle batteries are exactly right for a busy fork-lift truck, but probably over the top for chaps running a hobby engine at weekends. For hobby use, leisure batteries are a good compromise. A club might be better off investing in deep cycle batteries if they pull large numbers paying public around the track every weekend.

Motor ratings need close looking at. On it's own 100W or 150W written on the label is only indicative – the specification is incomplete. Is it input or output, and is it continuously rated or not? What limits the power of an electric motor is how hot it gets, and how much torque it can deliver, not what it says on the label. Many electric motors are not designed for continuous running, for example a petrol pump can expect to be used in short bursts, with time to cool-off between customers. This saves money, but can end in tears when a motor designed for a 20% duty cycle is fitted to a project requiring 100%. It's the quality of the insulation on the magnet wire that limits how hot before magic smoke. Older motors absolute max below 120°C, modern ones 150°C to 180°C, I've seen a motor spec quoting 220°C but that might have been a typo!

Motor input-output power, torgue and rpm specifications are best expressed as graphs. However, I found enough to reveal all in a table:

- The output power is about 100W, the input power about 150W. (NOT AT THE SAME TIME!)

- The rated torque is 0.35Nm at 2700rpm

- The rated current is 11.9A at 12v (142.8W) or 6A at 24V (144W) – doesn't matter, but note the slight difference.

- Conversion efficiency at least 78%

I'd interpret that to mean the motors are designed to run at a 'normal' 100W out, but that can be exceeded in short bursts (as in when fat bloke races his scooter uphill!) 78% of 144W in is 112W out. With four of them fitted to a 24V loco, the driver should avoid exceeding 4×6=24A, or 47.6A if wired for 12V. The spec doesn't give a duty cycle; scooters being short-range it's unlikely to be 100%, but it's probably more than good enough for a hobby loco. When the shunter is run for real keep an eye on the temperature of the motors; if they get hot, reduce the amount of work the loco is being asked to do. The good news is that your motors are designed for traction, and should do the job with no trouble. 400W is powerful on a track and you might not ever use all of it, but as a precaution, the closer your driving matches that of a scooter rider the better. And it probably will quite naturally!

Dave

Edited By SillyOldDuffer on 15/05/2019 10:44:00

15 May 2019 at 14:01 #409343Ron Laden

Participant@ronladen17547Thanks Dave,

I did base my decision to go with these motors on the fact that the labelled 150 watts is probably input with something like 100 watt output and I would be happy with 400 watts total. Dont ask me why but bench running the motors has led me to think that they may be a bit more than that though. It may be wishful thinking but I suspect I could have a total of 500 watts plus, the running of the loco will of course prove that or otherwise.

Ron

15 May 2019 at 17:07 #409363SillyOldDuffer

Moderator@sillyolddufferPosted by Ron Laden on 15/05/2019 14:01:10:Thanks Dave,

I did base my decision to go with these motors on the fact that the labelled 150 watts is probably input with something like 100 watt output and I would be happy with 400 watts total. Dont ask me why but bench running the motors has led me to think that they may be a bit more than that though. It may be wishful thinking but I suspect I could have a total of 500 watts plus, the running of the loco will of course prove that or otherwise.

Ron

Yes Ron you will, but you can't tell how much without making the motor do real work. Watts are a measure of the rate of doing work, so you have to make the motor do something serious to measure them.

All electric motors can deliver far more power output than it says on the label – for a while! Your motors aren't somehow limited to 100W maximum, the label only suggests that's the rate at which they can work comfortably. An electric motor can be pushed beyond its rating, but if it can't get rid of excess heat, the internal temperature will rise until the brushes burn or the insulation fails and shorts the motor out. If you run a heavily loaded 100W motor wired for 12V from a big 24V battery with thick wires, you should get at least 300W out.

Overloading motors is not recommended because it shortens their lives. As a general rule for a given weight the working life of a motor is inversely proportional to its power output.

I think your shunter has plenty of power in hand even if your motors can't maintain 100W continuous without overheating. Found the IMLEC results for 2010 here. The smallest engine measured had an average power output of 0.1 Drawbar HP (74W) and the largest 0.39 DBHP (291W). Most 5" gauge steam engines look to output less than 200 Watts.

And unlike electric motors which can be overloaded on demand, the power output of a steam engine is inherently throttled. Steam engines are held back by the rate at which steam can get into the cylinders and by the engine's ability to withstand violently reciprocating mechanical stresses.

Given decent batteries, I expect your shunter will perform like a sports car…

Dave

Edited By SillyOldDuffer on 15/05/2019 17:08:56

17 May 2019 at 16:46 #409667Ron Laden

Participant@ronladen17547Posted by SillyOldDuffer on 15/05/2019 17:07:42:Posted by Ron Laden on 15/05/2019 14:01:10:Thanks Dave,

I did base my decision to go with these motors on the fact that the labelled 150 watts is probably input with something like 100 watt output and I would be happy with 400 watts total. Dont ask me why but bench running the motors has led me to think that they may be a bit more than that though. It may be wishful thinking but I suspect I could have a total of 500 watts plus, the running of the loco will of course prove that or otherwise.

Ron

Yes Ron you will, but you can't tell how much without making the motor do real work. Watts are a measure of the rate of doing work, so you have to make the motor do something serious to measure them.

All electric motors can deliver far more power output than it says on the label – for a while! Your motors aren't somehow limited to 100W maximum, the label only suggests that's the rate at which they can work comfortably. An electric motor can be pushed beyond its rating, but if it can't get rid of excess heat, the internal temperature will rise until the brushes burn or the insulation fails and shorts the motor out. If you run a heavily loaded 100W motor wired for 12V from a big 24V battery with thick wires, you should get at least 300W out.

Overloading motors is not recommended because it shortens their lives. As a general rule for a given weight the working life of a motor is inversely proportional to its power output.

I think your shunter has plenty of power in hand even if your motors can't maintain 100W continuous without overheating. Found the IMLEC results for 2010 here. The smallest engine measured had an average power output of 0.1 Drawbar HP (74W) and the largest 0.39 DBHP (291W). Most 5" gauge steam engines look to output less than 200 Watts.

And unlike electric motors which can be overloaded on demand, the power output of a steam engine is inherently throttled. Steam engines are held back by the rate at which steam can get into the cylinders and by the engine's ability to withstand violently reciprocating mechanical stresses.

Given decent batteries, I expect your shunter will perform like a sports car…

Dave

Edited By SillyOldDuffer on 15/05/2019 17:08:56

Dave,

Assuming I am understanding the IMLEC 2010 results in your above link correctly I am amazed at the figures.

In first place a Brittania (4-6-2) which hauled 16 adults for 1/2 an hour using just 1.25 lbs of coal, surely that is high end efficiency. Also it is listed as having 0.35 drawbar HP (260 watts), I always thought of the larger model steam loco,s as having much more power than that.

Ron

Edited By Ron Laden on 17/05/2019 16:47:11

Edited By Ron Laden on 17/05/2019 16:49:21

Edited By Ron Laden on 17/05/2019 16:56:46

17 May 2019 at 17:50 #409671SillyOldDuffer

Moderator@sillyolddufferPosted by Ron Laden on 17/05/2019 16:46:12:Posted by SillyOldDuffer on 15/05/2019 17:07:42:Posted by Ron Laden on 15/05/2019 14:01:10:….…

Dave,

Assuming I am understanding the IMLEC 2010 results in your above link correctly I am amazed at the figures.

In first place a Brittania (4-6-2) which hauled 16 adults for 1/2 an hour using just 1.25 lbs of coal, surely that is high end efficiency. Also it is listed as having 0.35 drawbar HP (260 watts), I always thought of the larger model steam loco,s as having much more power than that.

…

Yes, the numbers are a little surprising, but when you dig into the figures there's a lot of energy in coal. Wikipedia gives 6.7kW hour per kilogram for coal. If Britannia converted coal at 100% efficiency, she would have output 260W for nearly 13 hours at IMLEC. Actually steam engines are poor converters of energy to work, usually well under 5% efficient. Your electric motors are 80% efficient or better.

260W is a third of a horse and applied correctly as on rails it can do a lot of work. I count 13 men on the roof in this Wikipedia picture of the Mumbles Horse Tram, and there are at least 4 more inside. That tram must weigh a bit too! Railway lines are a very effective way of moving heavy weights even without an engine because they are are low friction and flat.

Assuming your shunter's wheels gripped the track (railway engines need to be heavy), it would be powerful enough to haul the full-size Mumbles tram. Power-wise it's a big boy compared with most steam engines of the same gauge. It's weakness is the limited time it can keep going before the battery goes flat.

In theory, a steam loco could keep going forever by simply picking up more coal and water. In practice locomotives need a lot of maintenance : someone will know for sure, but I think full-size steam locomotives rarely managed more than 400 miles a day and then needed a good few hours in the shed getting ready for the next run. Electric trains are much more reliable, and energy efficient, and they out accelerate steam, and don't hammer the track. With a pickup system, electric trains are the bees knees. The main reason they're not universal is the high initial cost of wiring up the line.

In a sense steam engines are sheep in wolves clothing. Flame, smoke, steam, whistles, puffing, blowing off and pounding pistons make them look really impressive, and they smell the part too. Steam is dead sexy. But totally boring little electric motors easily outperform big reciprocating steam engines of the same power output. If it wasn't for those pesky batteries…

Dave

Edited By SillyOldDuffer on 17/05/2019 17:55:05

17 May 2019 at 18:01 #409674duncan webster 1

Participant@duncanwebster1400 Watts from a loco doing 8 mph (3.7 m/sec) is a tractive effort of 108 kgf. The best coefficient of adhesion you can rely on is about 3 (less on ally rail) so best make your loco weigh at least 325 kg, which is a hell of a lot. 108 kgf is enough to pull a train weighing over 5 tonnes up a 1 in 100 slope even allowing for rolling resistance.

I'd just settle for less power, say 200 watts. Even the Lionel Flippance machine in Dave's link only managed 300 watts average.17 May 2019 at 18:09 #409675An Other

Participant@another21905Just a thought: I know deep-discharge batteries are expensive, and will do the job, but it made me think a bit about what I would call the duty cycle of the loco. I would assume the batteries would be run down to the extent of needing a recharge every time they are used, but how often is the loco used?

I haven't done the figures, but could it not work out more economical to use standard batteries, despite the inability to handle continuous deep discharge, and have two, or even three sets? That would allow for a set in use, and a set charging, which may prevent deterioration occurring too early due to the discharge. I did a quick scan of batteries, and it seems to me that two sets of standard batteries could work out cheaper than one set of deep discharge batteries. This also could mean that early failure of one or more batteries is not so expensive.

I would assume also that during extended periods between the use of the batteries (winter?) then one would need to keep even the deep discharge batteries on some kind of trickle charge.

This thinking also does not take into account how difficult it may be to change a set of batteries 'at the trackside' – I guess if you need to dismantle the loco to do the job, then its a no-go.

I hope this makes sense – it was prompted by me thinking about the ever-increasing cost of items these days – in some ways these hobbies are becoming very expensive, and by the comments in the thread from people who seem happy with standard car batteries.

17 May 2019 at 19:10 #409684 BazyleParticipant@bazyle

BazyleParticipant@bazyleWhen I looked after the club electric loco 24v 40Ah class 08 shunter when used at the club running for an hour but not hauling passengers just the driver and maybe one extra it would recharge in half a hour or less. When used on the portable track at an event if the steamer had a problem it would be gasping after a couple of hours. So one of the things to consider is the attention span of your grandchildren.

17 May 2019 at 20:58 #409697duncan webster 1

Participant@duncanwebster1Posted by duncan webster on 17/05/2019 18:01:03:400 Watts from a loco doing 8 mph (3.7 m/sec) is a tractive effort of 108 kgf. The best coefficient of adhesion you can rely on is about 3 (less on ally rail) so best make your loco weigh at least 325 kg, which is a hell of a lot. 108 kgf is enough to pull a train weighing over 5 tonnes up a 1 in 100 slope even allowing for rolling resistance.

I'd just settle for less power, say 200 watts. Even the Lionel Flippance machine in Dave's link only managed 300 watts average.OOPS, sums wrong! Having a bad day, or at least that's my excuse

tractive effort is 108 Newtons, not kgf, so the weight only needs to be 33 kg, which is much more manageable. Max load up a 1 in 100 will then be 550 kg, about 7 people plus the loco

Edited By duncan webster on 17/05/2019 21:02:47

Edited By duncan webster on 17/05/2019 21:31:45

18 May 2019 at 08:51 #409734Ron Laden

Participant@ronladen17547Posted by duncan webster on 17/05/2019 20:58:11:Posted by duncan webster on 17/05/2019 18:01:03:400 Watts from a loco doing 8 mph (3.7 m/sec) is a tractive effort of 108 kgf. The best coefficient of adhesion you can rely on is about 3 (less on ally rail) so best make your loco weigh at least 325 kg, which is a hell of a lot. 108 kgf is enough to pull a train weighing over 5 tonnes up a 1 in 100 slope even allowing for rolling resistance.

I'd just settle for less power, say 200 watts. Even the Lionel Flippance machine in Dave's link only managed 300 watts average.OOPS, sums wrong! Having a bad day, or at least that's my excuse

tractive effort is 108 Newtons, not kgf, so the weight only needs to be 33 kg, which is much more manageable. Max load up a 1 in 100 will then be 550 kg, about 7 people plus the loco

Edited By duncan webster on 17/05/2019 21:02:47

Edited By duncan webster on 17/05/2019 21:31:45

Well thats a relief Duncan but I did suspect something not quite right, if I had a 5 inch – 400 watt loco capable of hauling 5 tonnes up a 1 in 100 I think I would have built the most powerful model the world had ever seen…

18 May 2019 at 09:57 #409739

18 May 2019 at 09:57 #409739martin perman 1

Participant@martinperman1Posted by SillyOldDuffer on 15/05/2019 10:39:32:Batteries, automotive, leisure, and deep cycle differ in their internal construction. They all have the same construction, but:

- car batteries are heavily optimised to deliver the short bursts of of high current needed to start an engine, and then to recharge as quickly as possible. They don't like being emptied. They are quickly spoiled when used to deliver ordinary current and/or trickle charged. They work, but have a short service life. Mass sales make them relatively cheap.

- Leisure batteries are designed to charge and discharge at more normal rates whilst providing a sensible service life. Not ideal to empty them, so good on boats/caravans etc where they can be used overnight, and then recharged during the day. They they tend to be pricey because their construction is more expensive than that of a car battery and the market isn't as competitive as that for car batteries. Will last a lot longer on a loco than a car-battery but not the best.

- Deep cycle batteries are like a leisure battery, but have been further optimised for deep discharge. The construction is like that of a super-leisure battery, ie more expensive.

Edited By SillyOldDuffer on 15/05/2019 10:44:00

As somebody else said theory and practice dont always match, I have just changed what I believe is the original car battery, the car was built in 2009 and the battery had a build date sticker of 2008. I changed it because if I left all the car doors opened, loading with camping gear etc or large loads, the interior lights drained it to a point where I couldn't turn the engine over but a jump start would sort it until the next time.

I have a five year old car battery which I use on my winch hauling my stationary engines in and out of my trailer from spring to summer and in between times and winter it sits on a trickle charger because I've found that the cold kills batteries unless they are constantly monitored and finally I have a leisure battery which gets used in my caravan, has started a car and generally anything else that I need 12volts for.

I also have two mobility scooters, my wifes and and mine, which sit connected to chargers all the time we dont need them.

Maybe the abuse I give them does them good.

Martin P

18 May 2019 at 10:39 #409744SillyOldDuffer

Moderator@sillyolddufferPosted by An Other on 17/05/2019 18:09:57:Just a thought: I know deep-discharge batteries are expensive, and will do the job, but it made me think a bit about what I would call the duty cycle of the loco. I would assume the batteries would be run down to the extent of needing a recharge every time they are used, but how often is the loco used?

I haven't done the figures, but could it not work out more economical to use standard batteries, despite the inability to handle continuous deep discharge, and have two, or even three sets?

…

I hope this makes sense – it was prompted by me thinking about the ever-increasing cost of items these days – in some ways these hobbies are becoming very expensive, and by the comments in the thread from people who seem happy with standard car batteries.

It does make sense – exactly the sort of thinking an engineer should apply to a problem. What's the cheapest way of achieving the desired result? Preconceptions, beliefs, opinion and what grandad was told in 1928 not allowed.

In theory car batteries used for traction will have a short-life. They degrade by losing capacity, an 60Ah battery successively converting itself into a 40Ah, 20Ah, or 5Ah, battery and then a door stop. What's hard to answer is how long a mistreated battery will last when used intermittently in a particular engine with an unknown duty cycle. Chatting casually to owners at the track-side may not help. In the absence of proper data, it's hard to tell the difference between the chap who's just fitted a new battery, and the chap who has a battery going strong after 5 years experience. Only the second is worth talking to!

My practical experience of ruining car batteries comes from amateur radio. In my youth this took me up hill-tops with a radio transceiver to take part in competitions. I'd do it perhaps 3 weekends each summer. Car batteries were the obvious source of power – a 12V transceiver would draw about 100mA continuously on receive, and a peaky 6A on transmit, perhaps 20% of the time. In theory a car battery has more than enough storage to cope with 48 hours of busy radio fun. On return home, the car battery was trickle charged ready for the next outing.

Admittedly the radio pattern of discharge/recycle is even more abusive than traction, but radio competition killed a new car battery in about 3 months: expensive! It's the pattern of slow deep discharge coupled with slow recharging that seems to do most damage. The same transceiver fitted to a car, where the battery also does normal motoring duty, does not kill the battery.

I think a £100 car battery that lasted 3 years on the track would be a bargain. An expensive mistake if it only lasted 3 months. Theory is a helpful way of avoiding expensive mistakes, but it always needs to be validated in the real world. Be really good for owners to share their practical experiences, especially anyone who has successfully used the same car battery for more than 2 years.

Dave

Edit: I typed this before reading Martin's contribution. We agree about theory and practice!

Edited By SillyOldDuffer on 18/05/2019 10:42:50

18 May 2019 at 11:17 #409751Ron Laden

Participant@ronladen17547I have gone with a pair of mobility scooter batteries 12 volt – 22 amp hour in the little 0-4-0 shunter, the 4 motors are wired parallel as are the batteries giving 12 volt – 44 amp hours, its early days so will have to see how they cope over time. Cost wise they compared favourably with a 50 amp hour leisure battery which I was going to use, £65 for the leisure and £63 for the pair of scooter batteries.

I am thinking of going with the same for the large loco but 4 batteries, each pair wired series for 24 volt and then the two pairs in parallel to double the capacity though I may go up to 30 amp hour doubled to 60, the 4 motors will be wired parallel also.

I dont yet have any long term experience with the batteries but we have a club member who runs an electric with a pair of the mobility scooter batteries and he said the batteries are coming up 4 years old and still going strong. I have noticed though its quite light duty, he probably does no more than three or four 10 minute runs each track visit.

22 May 2019 at 13:52 #410399Ron Laden

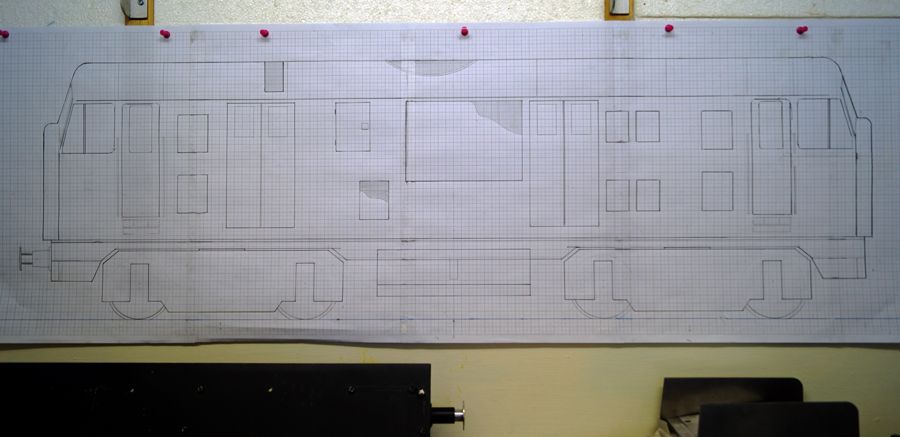

Participant@ronladen17547Not too good a photo of it but I sketched up the loco to get a feel for the size, twice as long (45 inches) as the 0-4-0 shunter. Looks as if it will lend itself to some good detail though over 20 fine grid vent panels may prove to be fun, it would be good if I can find some off the shelf material for those. Waiting the arrival of some metal and then I can make a start on the chassis.

Click picture to enlarge.

Edited By Ron Laden on 22/05/2019 13:57:09

24 May 2019 at 08:43 #410693Ron Laden

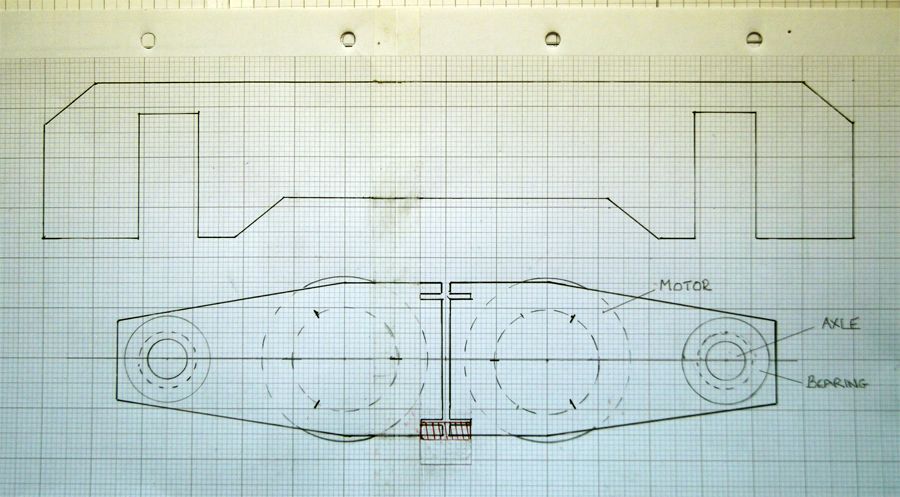

Participant@ronladen17547Another sketch showing a design change to the bogie and motor mounts, I,m sure that the previous design for the bogies would have worked well enough but I wasnt happy with the shape and the way they looked. The bogie side plates were too deep top to bottom but that came about with mounting the motors to the plates.

The sketch below shows the plates more to the shape they should be though this wouldnt allow for fixing the motors to them, well not without some bracketry but I dont fancy that. So I have looked at axle mounting the motors, I did this on the 0-4-0 and it worked out well. The 0-4-0 has a single plate running on the axle with a motor mounted each side, I used tie bars and nylon guide rollers to retain (prevent rotation) of the plate whilst allowing the plate vertical movement with the sprung axle.

I dont have the space to do the same with the new shape bogie side plates so I have come up with the idea as seen in the sketch, with the limited space the problem was how to retain the motor plates whilst allowing for the vertical travel of the axle. The pair of plates would be sized and centered to leave a 3mm gap between them this would allow for a small amount of movement and retained to each other via a pair of strong compression springs, I have left off the top spring for clarity. The motors and motor plates will still protrude down past the bogie side plates but they will be inset by 25mm so shouldnt be too obvious. I think this should work but if I am missing the obvious please shout.

24 May 2019 at 10:52 #410709duncan webster 1

Participant@duncanwebster1The usual way to prevent motor assemblies rotating around the wheel axles is by tie bars from the motor mount to the fixed bit of bogie. It is also better to have the pull point from the bogies to the main frame as low as possible to reduce weight transfer. Can you not have the motors higher, protruding from the top of the bogie frame, they would be inside the body

24 May 2019 at 13:01 #410725Ron Laden

Participant@ronladen17547Posted by duncan webster on 24/05/2019 10:52:55:The usual way to prevent motor assemblies rotating around the wheel axles is by tie bars from the motor mount to the fixed bit of bogie. It is also better to have the pull point from the bogies to the main frame as low as possible to reduce weight transfer. Can you not have the motors higher, protruding from the top of the bogie frame, they would be inside the body

Hi Duncan, I,ve never been one for the usual I do like to look at new ideas, not that they all work out of course. I did use tie bars on the 0-4-0 and they were ok. I will give what you suggest some thought but I was just working on a fresh approach whilst trying to keep parts and assembly quite simple.

Ron

25 May 2019 at 15:27 #410920Ron Laden

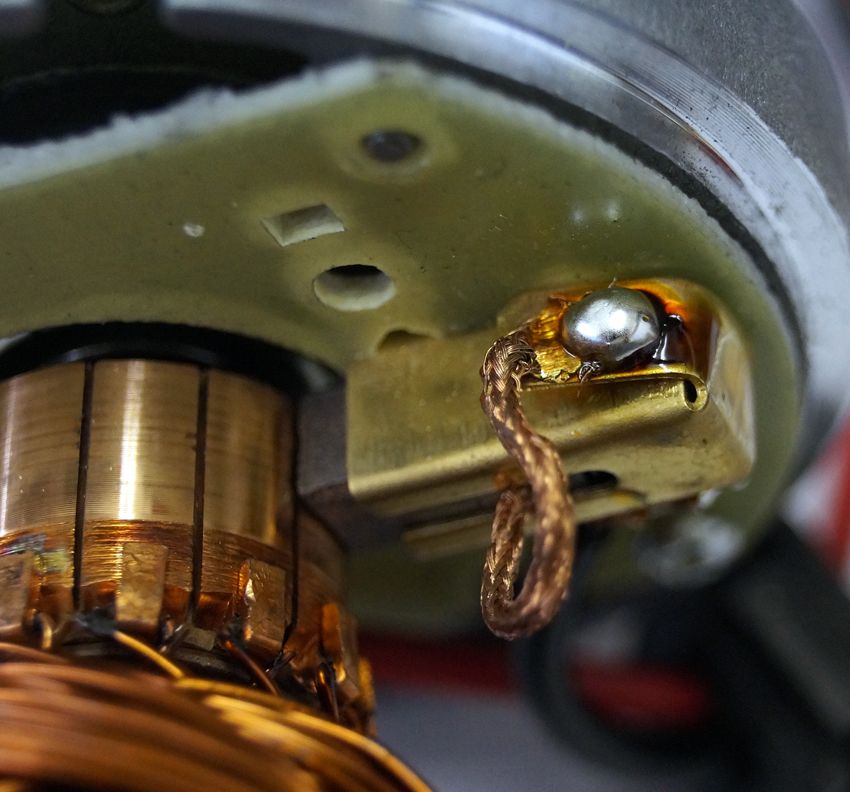

Participant@ronladen17547The 4 motors need a couple of mods, the first is soldering the brush wires. The wires are crimped in place under a tab and quite secure actually but I have gone belt and braces and soldered them just in case.

The motors will be sandwiched between a pair of mounting plates but there is only mounting holes (3 x M5) in the output shaft end casing. The rear end casing needs holes adding but the casing is cast aluminium and only 2.5mm thick, so I am going to drill and thread M5 and fix the screws in from the inside using retainer. There will be plenty of clearance between the screw heads and the armature and it will leave threaded studs on the outside for fixing to the plate using nuts, should be ok.

11 June 2019 at 09:02 #413661Ron Laden

Participant@ronladen17547Morning guys,

I would appreciate peoples thoughts on the following:

On the bogie axle/drive assy I currently have the shoulder of an oilite bearing which at times can contact the revolving face of an aluminium drive pulley. The axle/wheel to which the pulley is fixed has 0,040" end float so contact wont be constant but there will be contact at times. The faces of the oilite and the pulley are very smooth and I am wondering if keeping them lubricated would work ok or is the aluminium eventually going to wear and pick up.

I have some thin 0.015" nylon washers, would it be a better option to fit one of those between the faces. I would prefer to keep things simple but I could bore the pulley and fit a shouldered bush either oilite or some other material so it is the two shoulders that make contact.

Thanks

Ron

Edited By Ron Laden on 11/06/2019 09:03:10

Edited By Ron Laden on 11/06/2019 09:03:32

11 June 2019 at 10:52 #413683SillyOldDuffer

Moderator@sillyolddufferPosted by Ron Laden on 11/06/2019 09:02:33:Morning guys,

I would appreciate peoples thoughts on the following:

On the bogie axle/drive assy I currently have the shoulder of an oilite bearing which at times can contact the revolving face of an aluminium drive pulley. The axle/wheel to which the pulley is fixed has 0,040" end float so contact wont be constant but there will be contact at times. The faces of the oilite and the pulley are very smooth and I am wondering if keeping them lubricated would work ok or is the aluminium eventually going to wear and pick up.

I have some thin 0.015" nylon washers, would it be a better option to fit one of those between the faces. I would prefer to keep things simple but I could bore the pulley and fit a shouldered bush either oilite or some other material so it is the two shoulders that make contact.

Thanks

Ron

Edited By Ron Laden on 11/06/2019 09:03:10

Edited By Ron Laden on 11/06/2019 09:03:32

My suggestion comes from Meccano lore, and may not be completely respectable!

By putting a loose washer or two between a wheel and frame, friction is said to be reduced because the wheel can slip on the washer and the washer can slip on the frame. Not sure of the logic but it seems to work.

I'd fit the Nylon washers; if nothing else they'd protect the expensive Oliite bearings from the Aluminium and stop the bearing grinding the Aluminium and making a lot of abrasive Oxide, which is not good if it gets inside a bearing. (Bit theoretical because even badly abused bearings might last donkey's years on a lightly used locomotive.)

Dave

11 June 2019 at 14:27 #413708Ian S C

Participant@ianscRon, I'd tend to use hard shim washers, similar to those found in electric motors, if I need them, and can't find what I want in the junk box I go to my bearing supplier who has all those sort of goodies. Some times there is a nylon/plastic washer between two steel washers.

Ian S C

-

AuthorPosts

- Please log in to reply to this topic. Registering is free and easy using the links on the menu at the top of this page.

Latest Replies

Home › Forums › Locomotives › Topics

-

- Topic

- Voices

- Posts

- Last Post

-

-

“swedish iron”

Started by:

moonman in: Materials

- 2

- 2

-

12 July 2025 at 03:42

Fulmen

Fulmen

-

TurboCAD – Alibre File Transfers.

Started by:

Nigel Graham 2 in: CAD – Technical drawing & design

- 1

- 1

-

12 July 2025 at 00:00

Nigel Graham 2

-

Another Day … Another ScumBag

Started by:

Michael Gilligan

in: The Tea Room

Michael Gilligan

in: The Tea Room

- 11

- 17

-

11 July 2025 at 23:05

Windy

Windy

-

Sat nag

1

2

Started by:

duncan webster 1 in: The Tea Room

- 14

- 27

-

11 July 2025 at 22:58

Nigel Graham 2

-

buying machine tools from aliexpress experiences?

Started by:

Jake Middleton-Metcalfe in: Manual machine tools

- 14

- 17

-

11 July 2025 at 22:26

Versaboss

-

Adjustable spanner thread direction

Started by:

jimmy b

in: Workshop Tools and Tooling

jimmy b

in: Workshop Tools and Tooling

- 8

- 8

-

11 July 2025 at 22:14

Nimble

-

Chester Champion, warco ZX15 drawbar

Started by:

martian in: Manual machine tools

- 5

- 7

-

11 July 2025 at 21:51

Howard Lewis

-

Bosch PBD 40 bearing upgrade

Started by:

th1980 in: Manual machine tools

- 6

- 12

-

11 July 2025 at 21:33

Howard Lewis

-

Square end on round stock – Milling?

1

2

Started by:

Roger TheShrubber in: Workshop Tools and Tooling

- 17

- 30

-

11 July 2025 at 21:23

Howard Lewis

-

motor and switch wiring Myford ML7

Started by:

1957jmh in: Workshop Tools and Tooling

- 4

- 6

-

11 July 2025 at 21:09

Howard Lewis

-

I’m Under Pressure

1

2

Started by:

howardb in: Related Hobbies including Vehicle Restoration

- 16

- 30

-

11 July 2025 at 19:12

Nealeb

-

Farm Boy

1

2

…

4

5

Started by:

Dalboy in: I/C Engines

- 15

- 102

-

11 July 2025 at 18:48

Diogenes

-

Sanjay’s Banjo Engine

Started by:

JasonB

in: Stationary engines

JasonB

in: Stationary engines

- 3

- 9

-

11 July 2025 at 17:32

renardiere7

-

Old plastic handled screwdrivers

Started by:

Dave Halford

in: Workshop Tools and Tooling

Dave Halford

in: Workshop Tools and Tooling

- 12

- 14

-

11 July 2025 at 17:14

Robert Atkinson 2

Robert Atkinson 2

-

Bridgeport ways and wear

Started by:

inline in: Manual machine tools

- 7

- 18

-

11 July 2025 at 09:16

Ian Owen NZ

-

Maisie lubricator

Started by:

ferroequinologist in: Locomotives

- 9

- 14

-

11 July 2025 at 09:09

Clive Foster

-

Transwave converter – plugged in motor, tripped RCD

Started by:

ell81 in: Beginners questions

- 8

- 12

-

10 July 2025 at 22:56

Master of none

-

Eight Trains

Started by:

Vic

in: The Tea Room

Vic

in: The Tea Room

- 1

- 1

-

10 July 2025 at 14:14

Vic

Vic

-

Help Wire 3 Phase 2 Speed Motor

Started by:

Allan Day in: Electronics in the Workshop

- 13

- 23

-

10 July 2025 at 11:57

Andrew Skinner

-

Easiest/cheapest source of R8 socket

Started by:

Beardy Mike in: Workshop Tools and Tooling

- 8

- 10

-

10 July 2025 at 10:16

Pete

-

New (but well aged) member

Started by:

mikemunson in: Introduce Yourself – New members start here!

- 6

- 6

-

10 July 2025 at 09:23

Dell

Dell

-

Bearing boxes for ball race

Started by:

Paul McDonough in: Beginners questions

- 11

- 20

-

9 July 2025 at 20:38

old mart

-

Twin Engineering’s heavy mill/drill quill removal

1

2

Started by:

Martin of Wick in: Manual machine tools

- 11

- 34

-

9 July 2025 at 19:42

old mart

-

File backup to external hard drive, incremental etc?

Started by:

Peter Bell in: The Tea Room

- 11

- 17

-

9 July 2025 at 13:50

Graham Stoppani

Graham Stoppani

-

Boiler Design – issue 4765

1

2

…

7

8

Started by:

Charles Lamont in: Model Engineer & Workshop

- 26

- 186

-

9 July 2025 at 12:28

Paul Kemp

-

“swedish iron”

-

Latest Issue

Newsletter Sign-up

Latest Replies

- “swedish iron”

- TurboCAD – Alibre File Transfers.

- Another Day … Another ScumBag

- Sat nag

- buying machine tools from aliexpress experiences?

- Adjustable spanner thread direction

- Chester Champion, warco ZX15 drawbar

- Bosch PBD 40 bearing upgrade

- Square end on round stock – Milling?

- motor and switch wiring Myford ML7