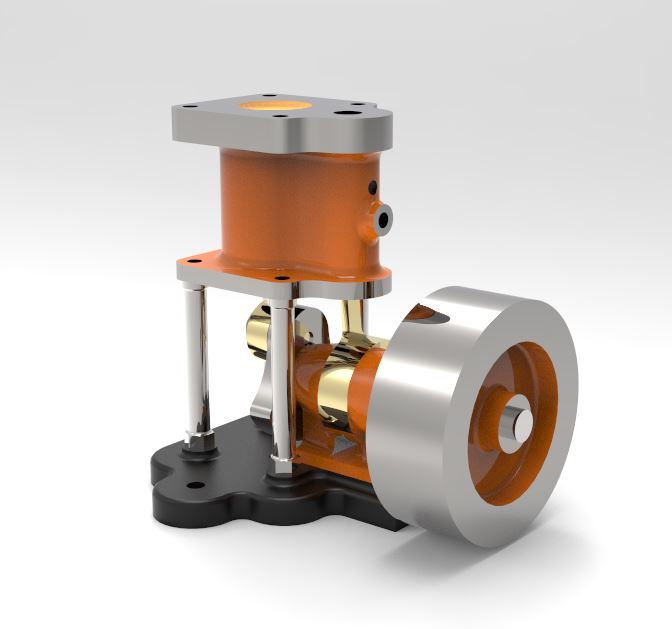

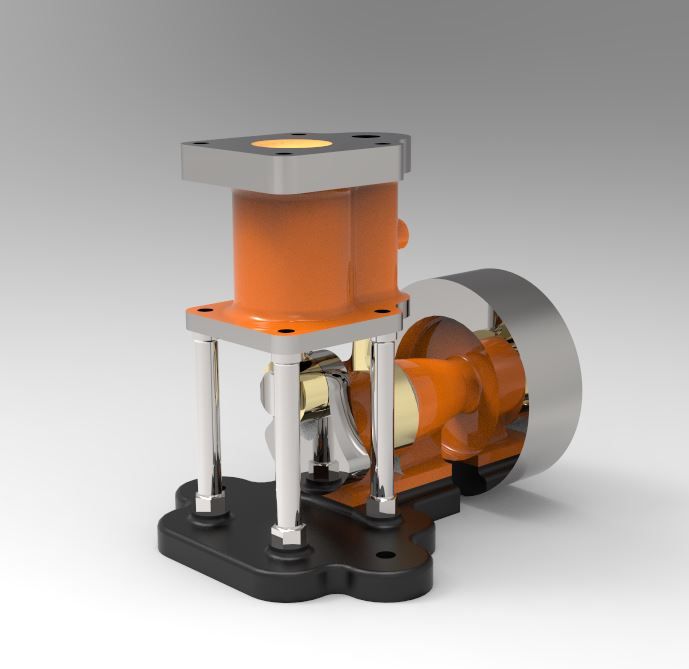

I debated about how to make the cylinder which I wanted to do from Cast Iron. I could have CNCd it from a solid block cutting from both sides but as not that many people have a CNC I went for a JBWelded fabrication which although I did use the CNC to cut the parts they could also be done manually.

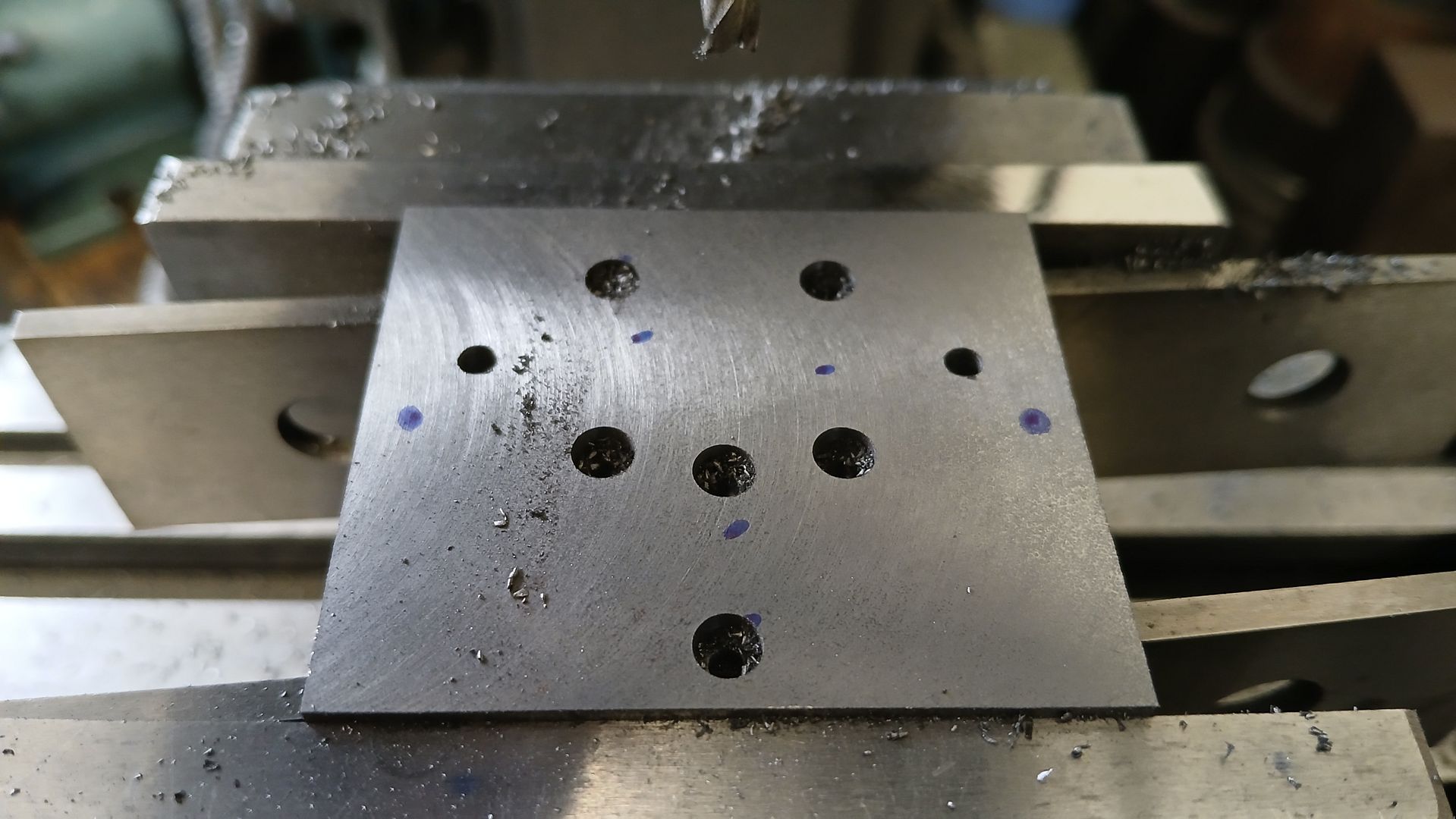

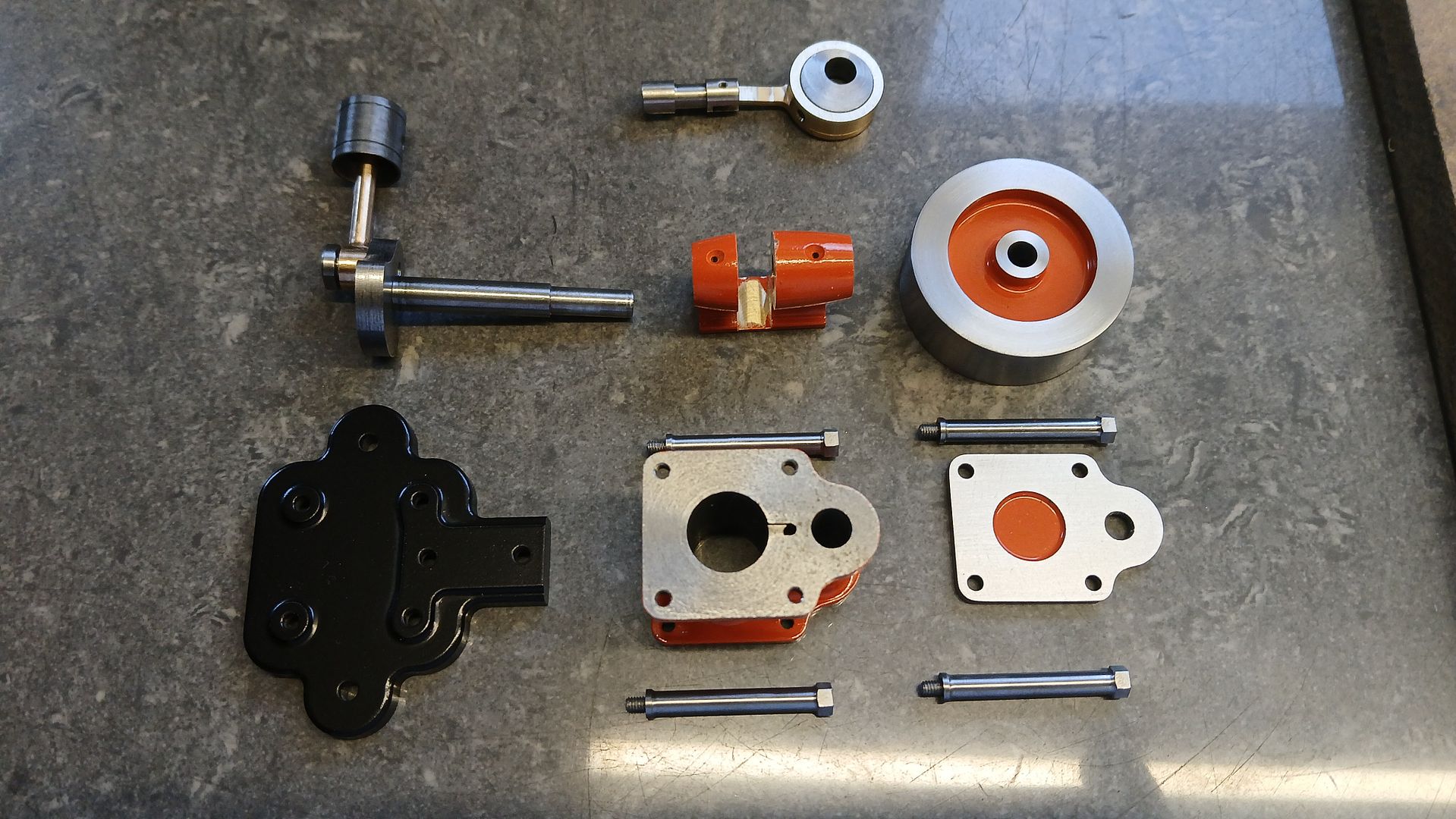

The first job was to prepare three flat rectangles, two for the flanges and another for the cylinder end cover. These had the four holes drilled into them so that I could screw them to a tooling block to shape the profile and also cut a decorative recess in the top of the cover.

The cylinder itself was cut from a piece sawn from an unused casting including a spigot to locate one of the flanges and a spot drilled hole so it could be clocked up in the 4-jaw.

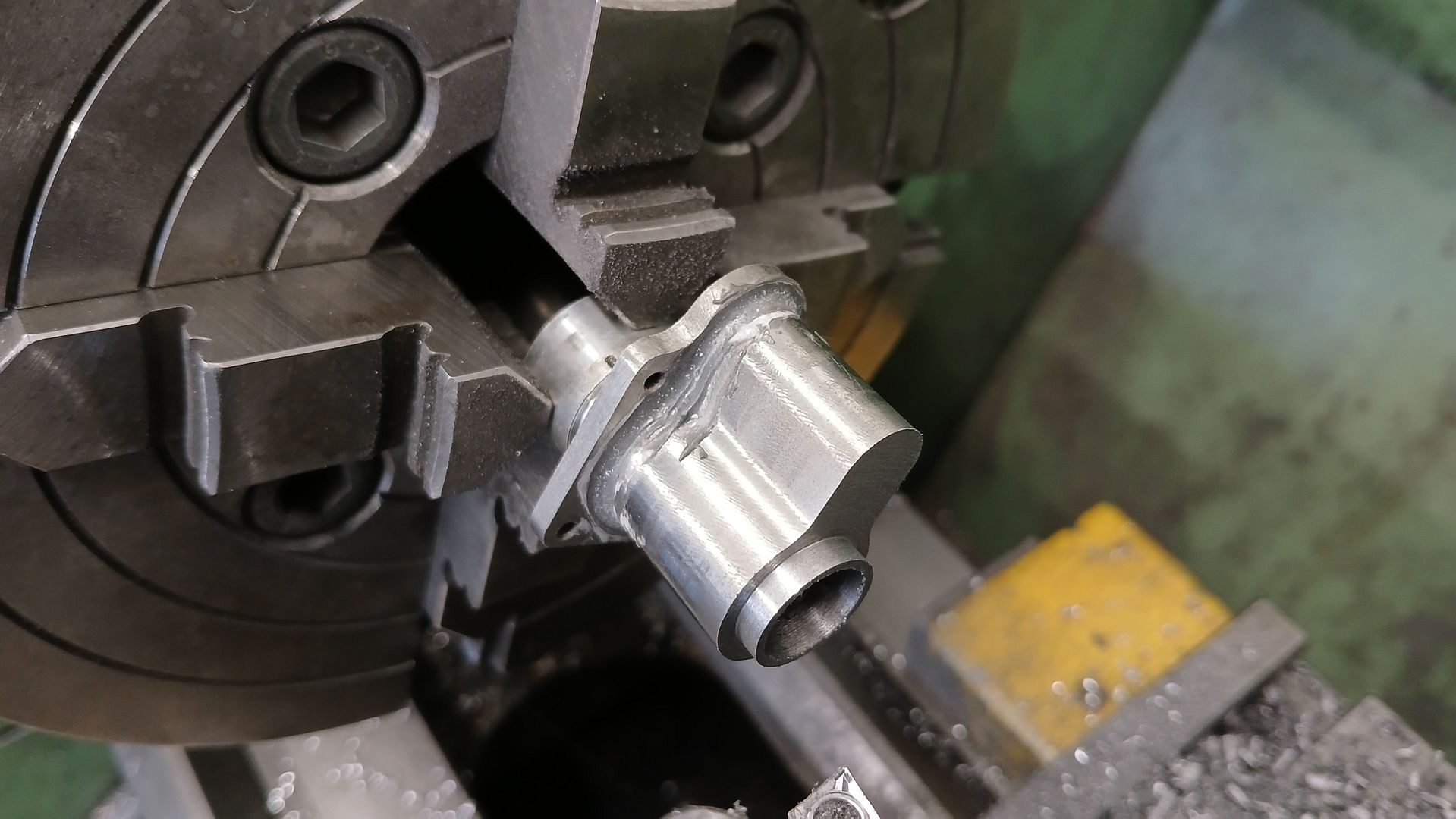

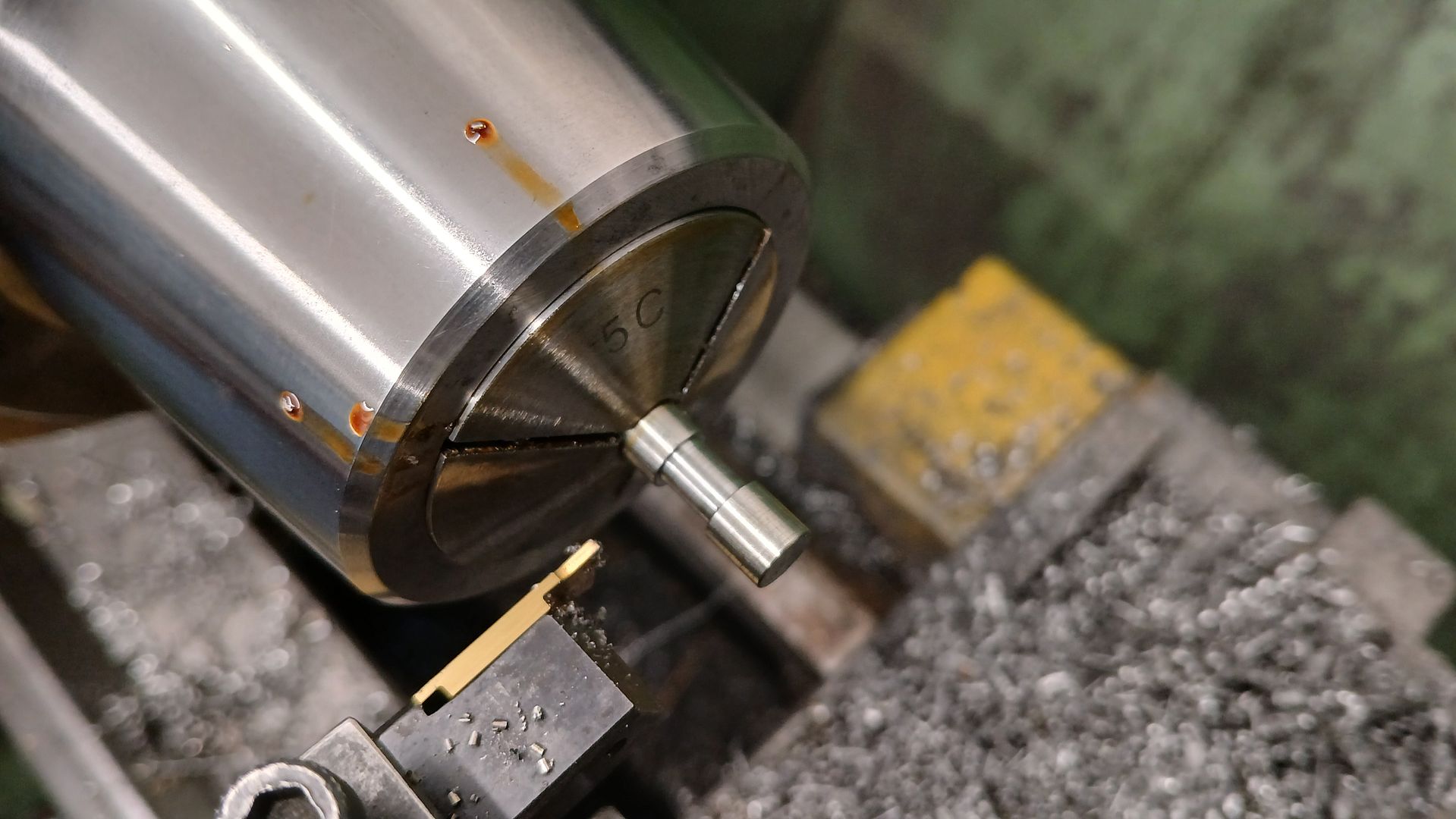

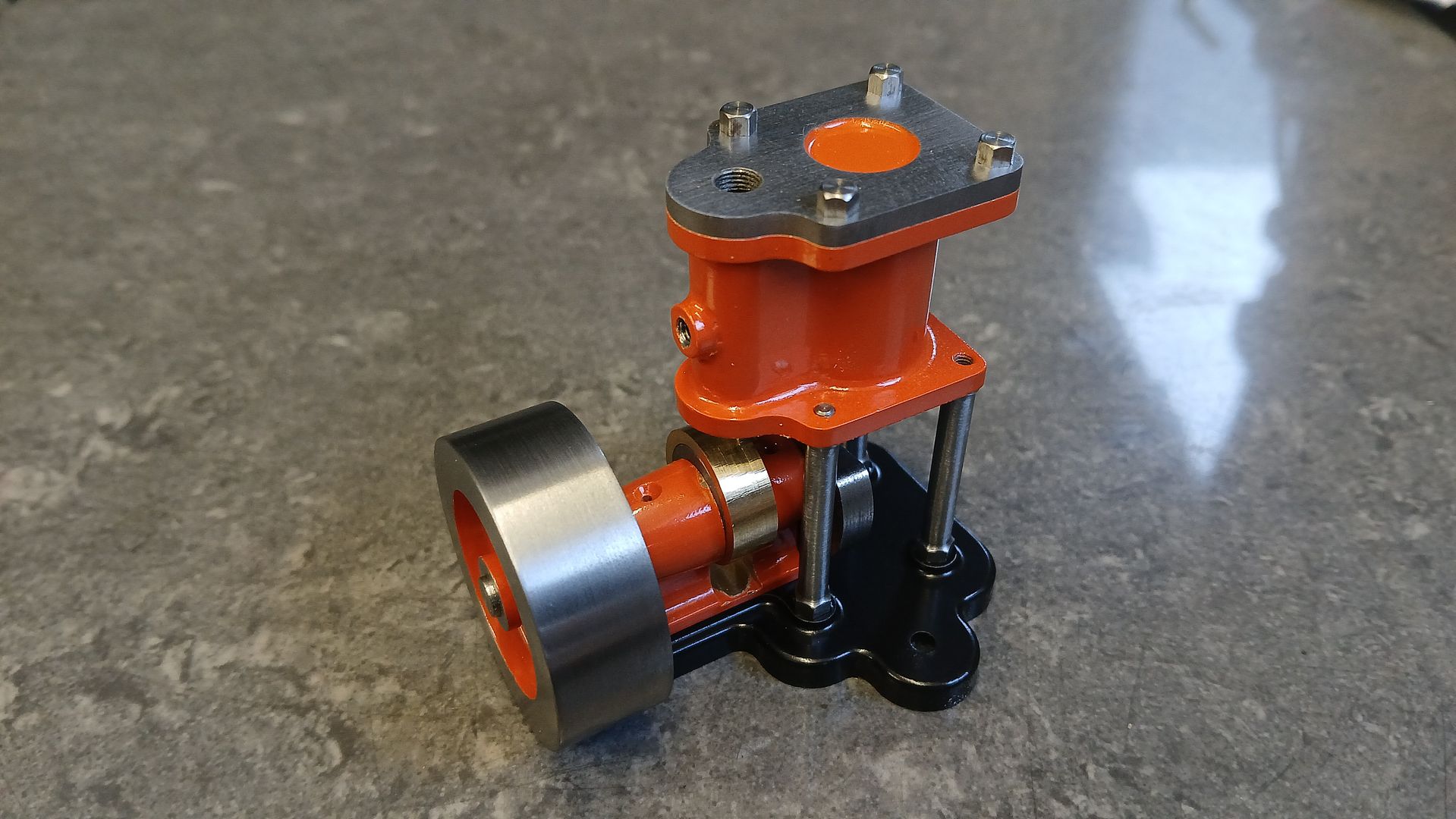

One of the over thick flanges was bonded onto the spigot with JB Weld and after leaving it to go off the cylinder was clocked true in the 4-jaw to be drilled and bored to 12mm, I also faced off the flange at the same setting so that it was true to the bore and marked this as the bottom flange.

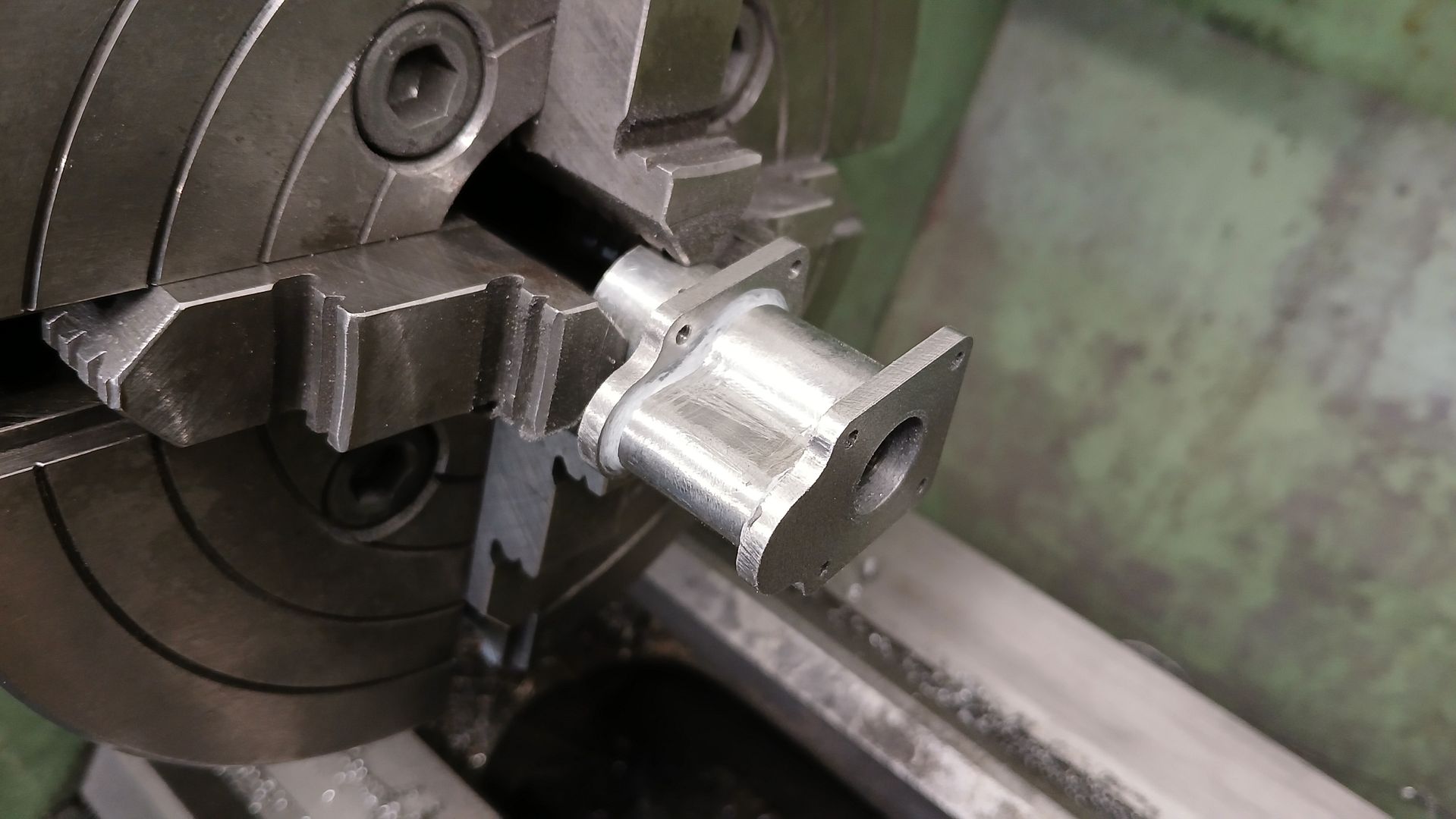

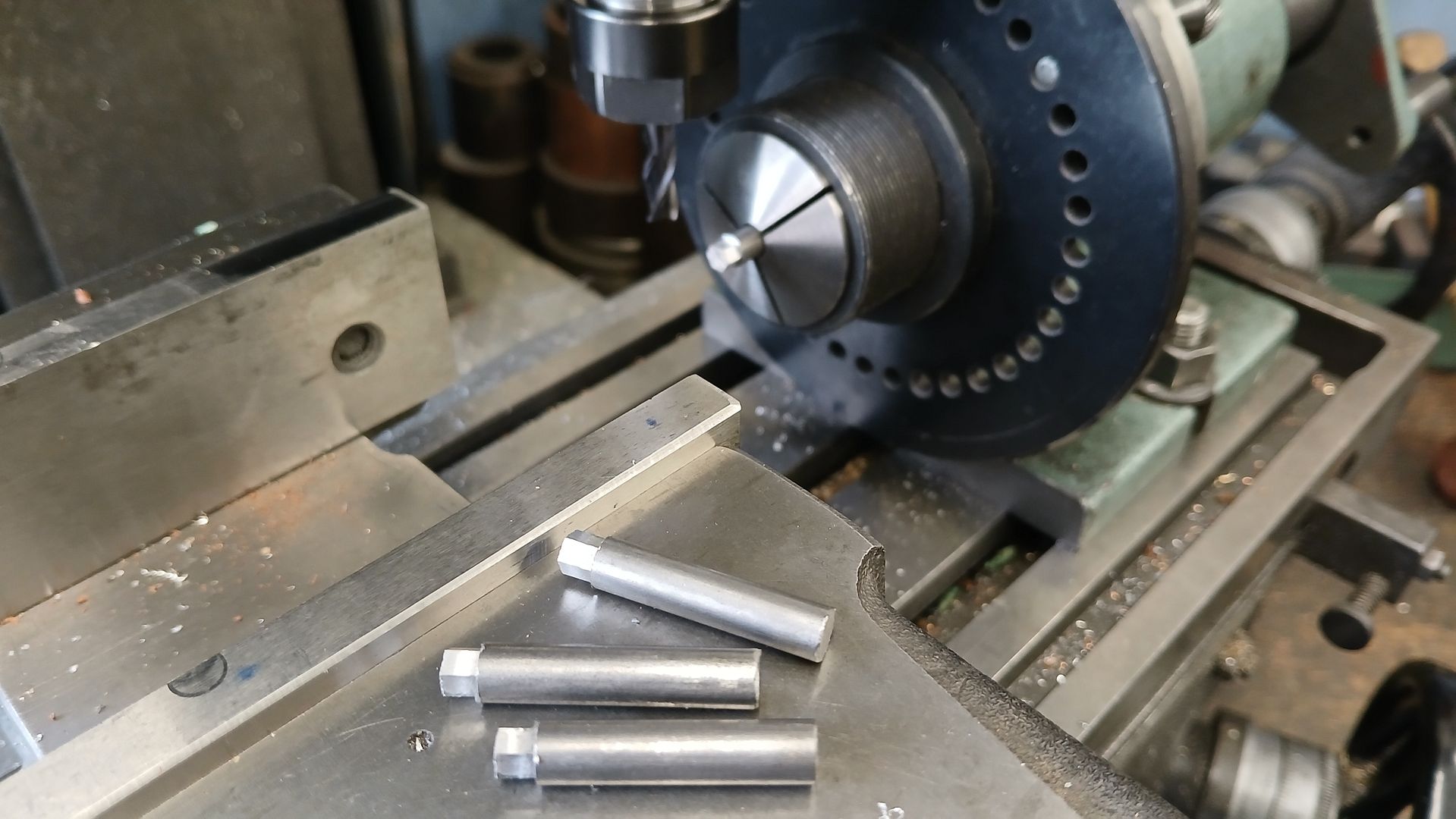

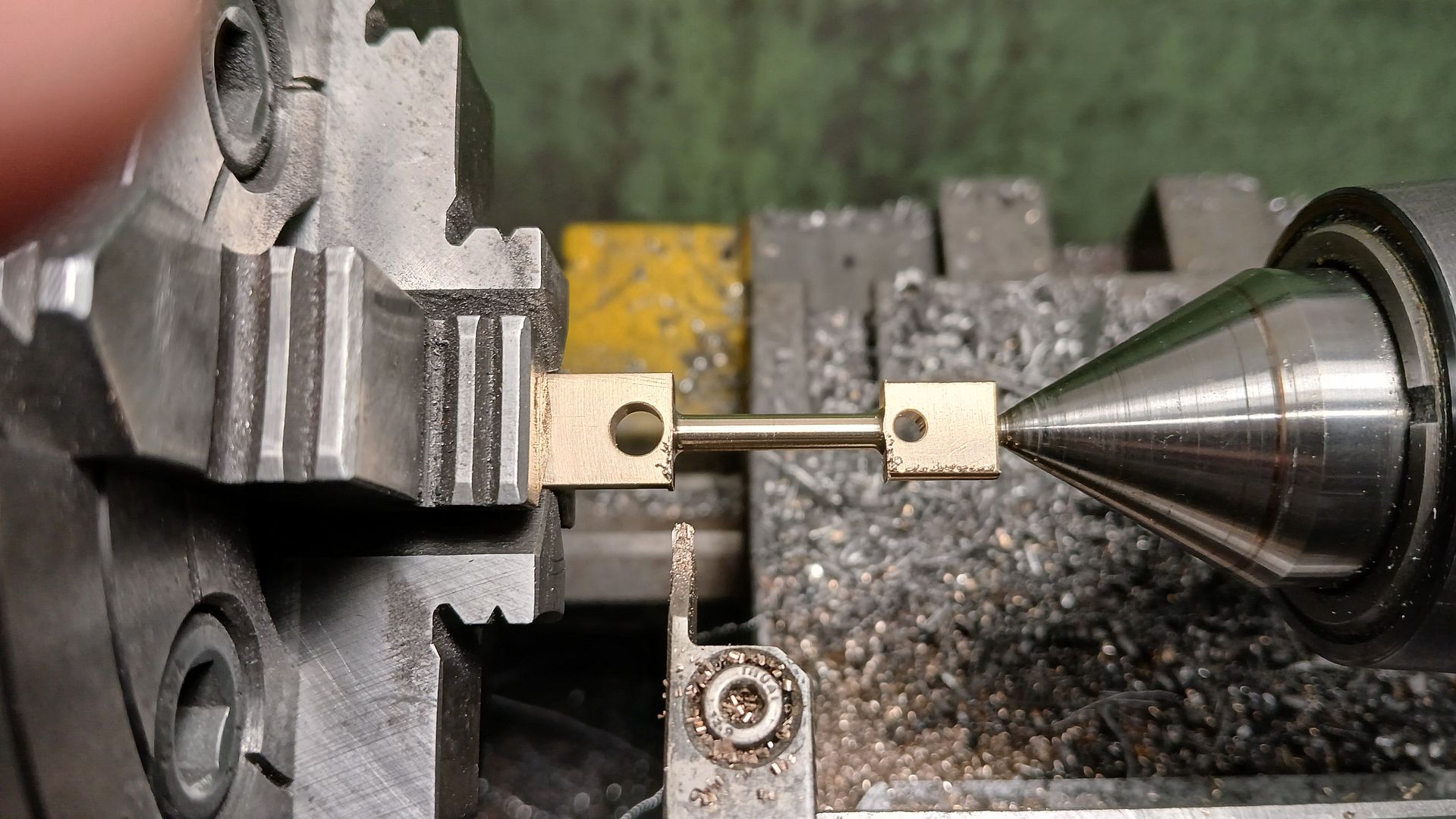

An old expanding arbor was turned down to fit the bore of the new cylinder

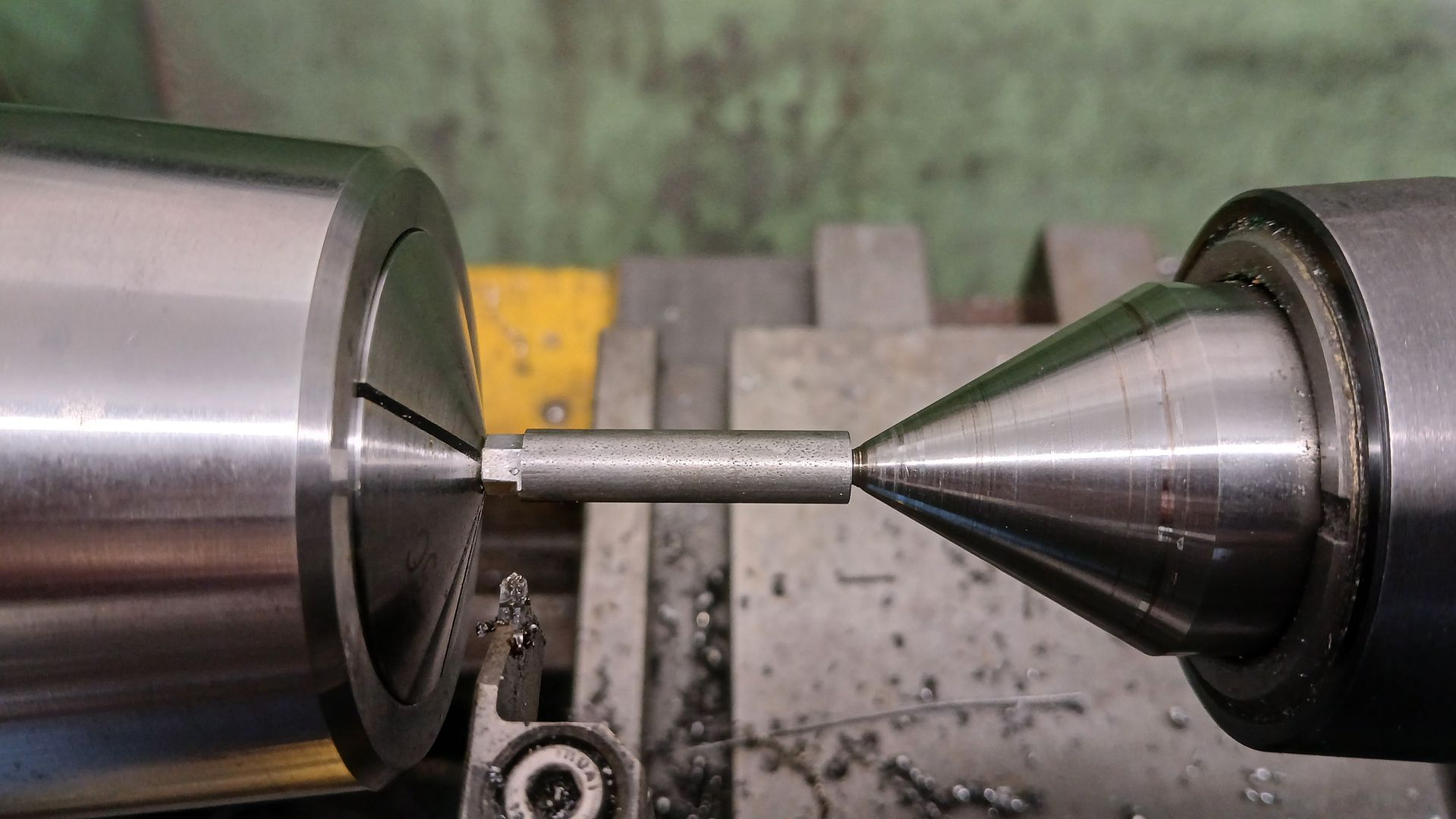

Using the arbor the other end of the cylinder could have it’s spigot machined ready to bond on the top flange. And once that had set it was faced back to final size

The bore was then lapped down to 600g

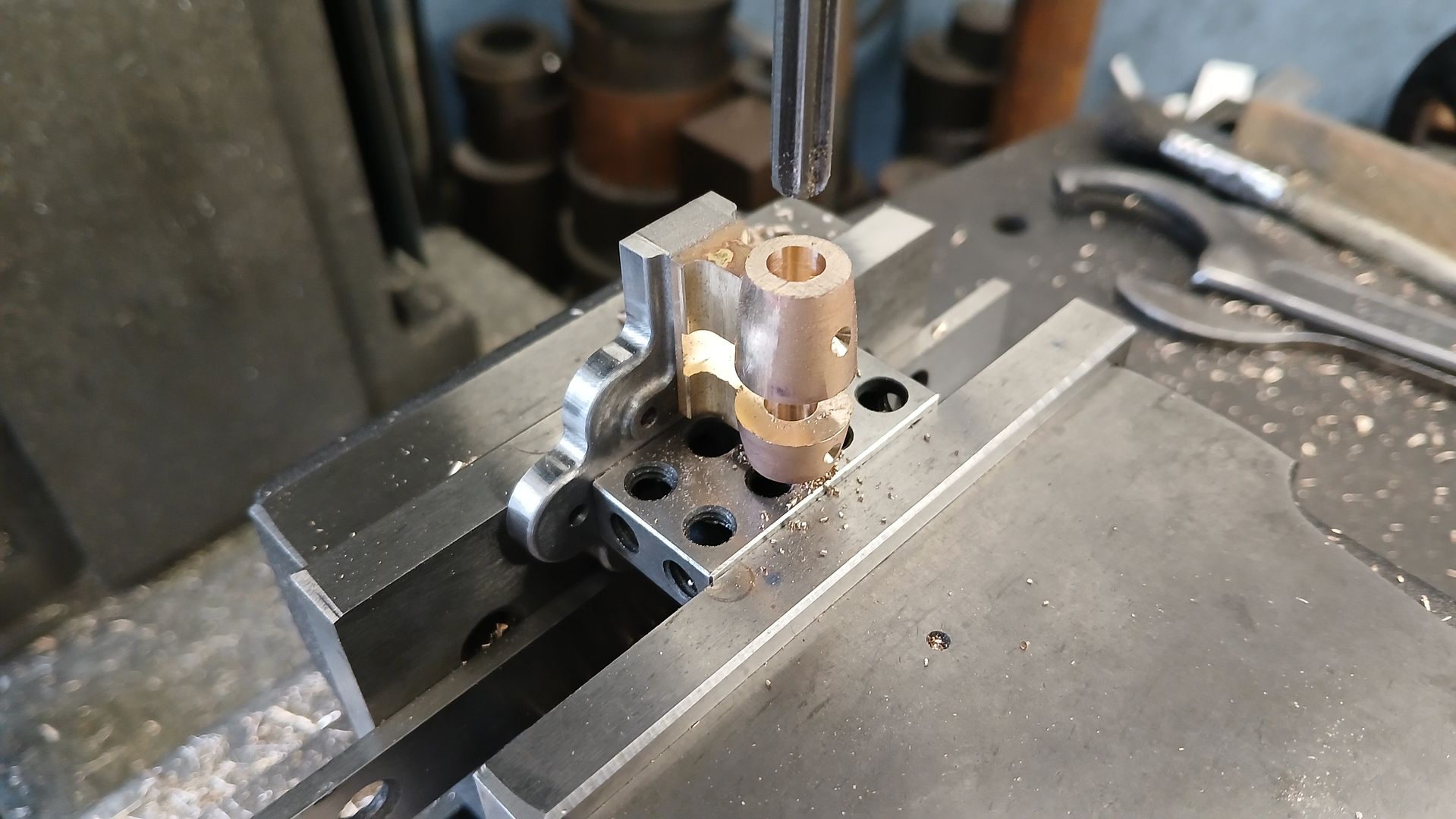

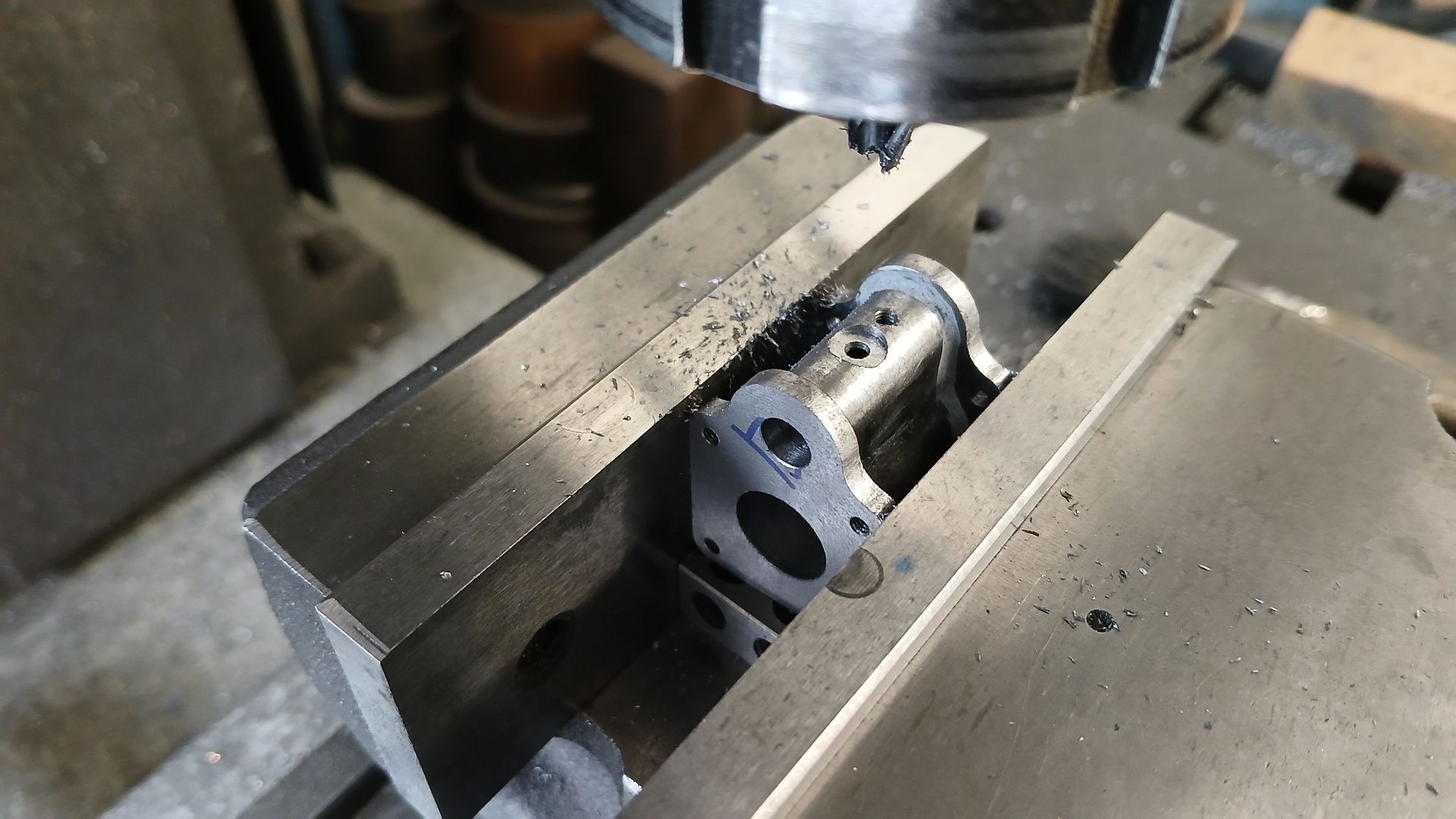

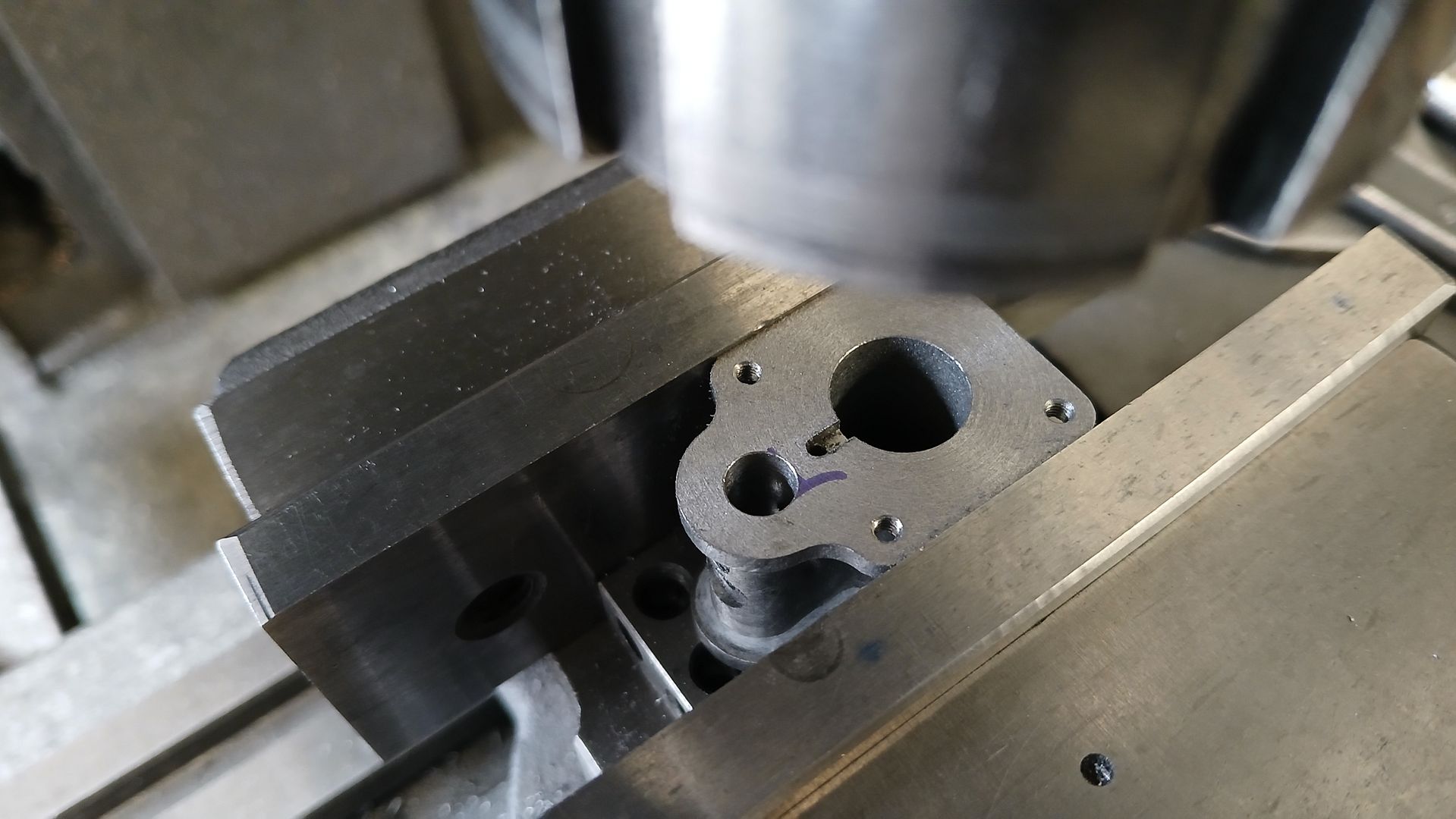

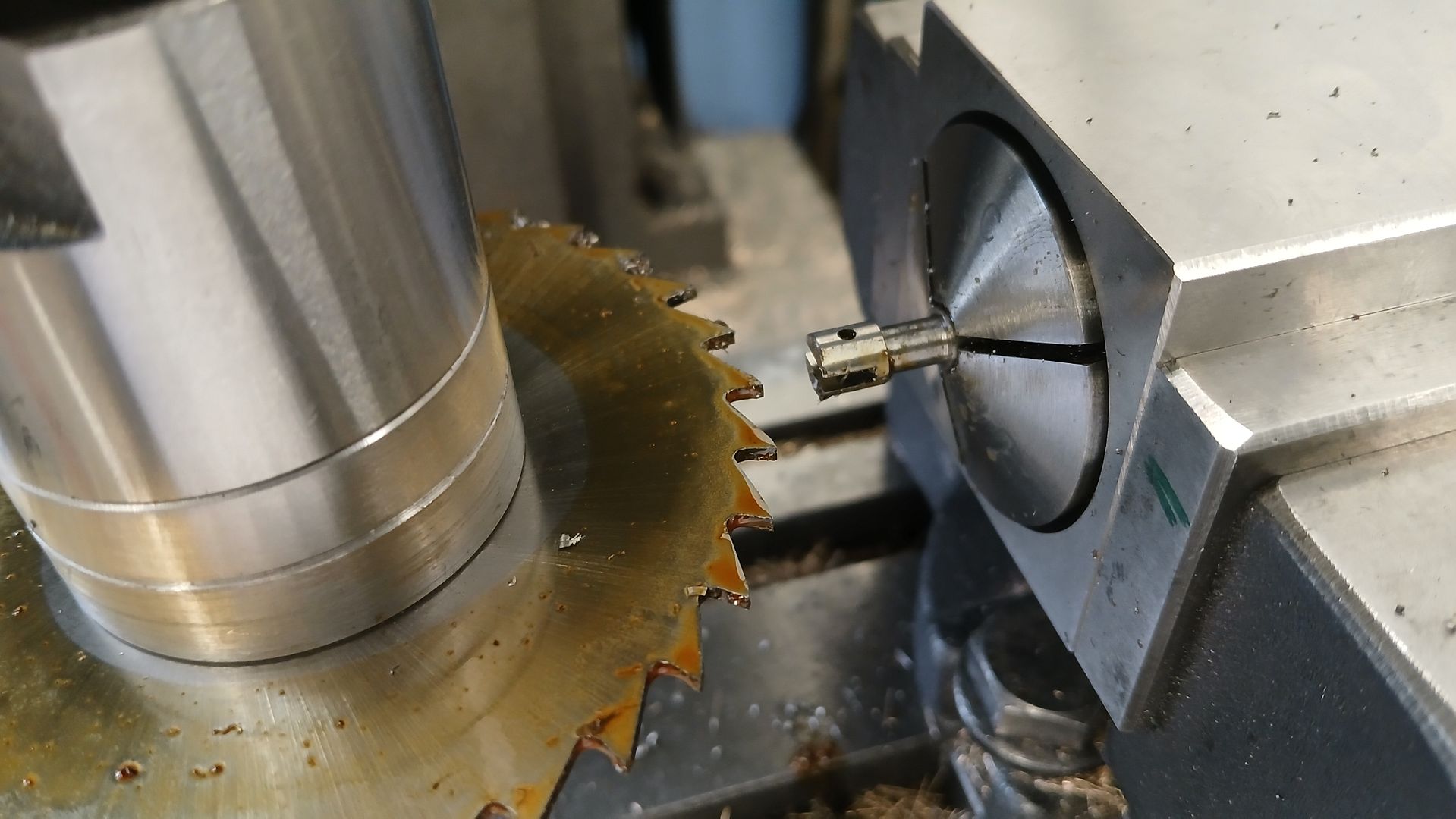

Over to the mill and the valve hole was drilled 5.8mm and then reamed to 6mm. Then with it horizontal the inlet hole was drilled and counterbored for a small threaded boss to be bonded in. The tapped hole next to it connects the valve chamber to a vertical hole which takes the air/steam up to the top of the cylinder, the outer part of this hole gets plugged.

From the top the hole down to the plugged one is drilled and a connecting slot to the main bore milled 1.5mm x 1.5mm.

.

JasonB.

JasonB.