Back by popular demand!

Cam Follower and Valve

Drawing #12

Cam Follower

A simple turning job from brass, face off, drill 2.0mm and part off to 2.0mm thick

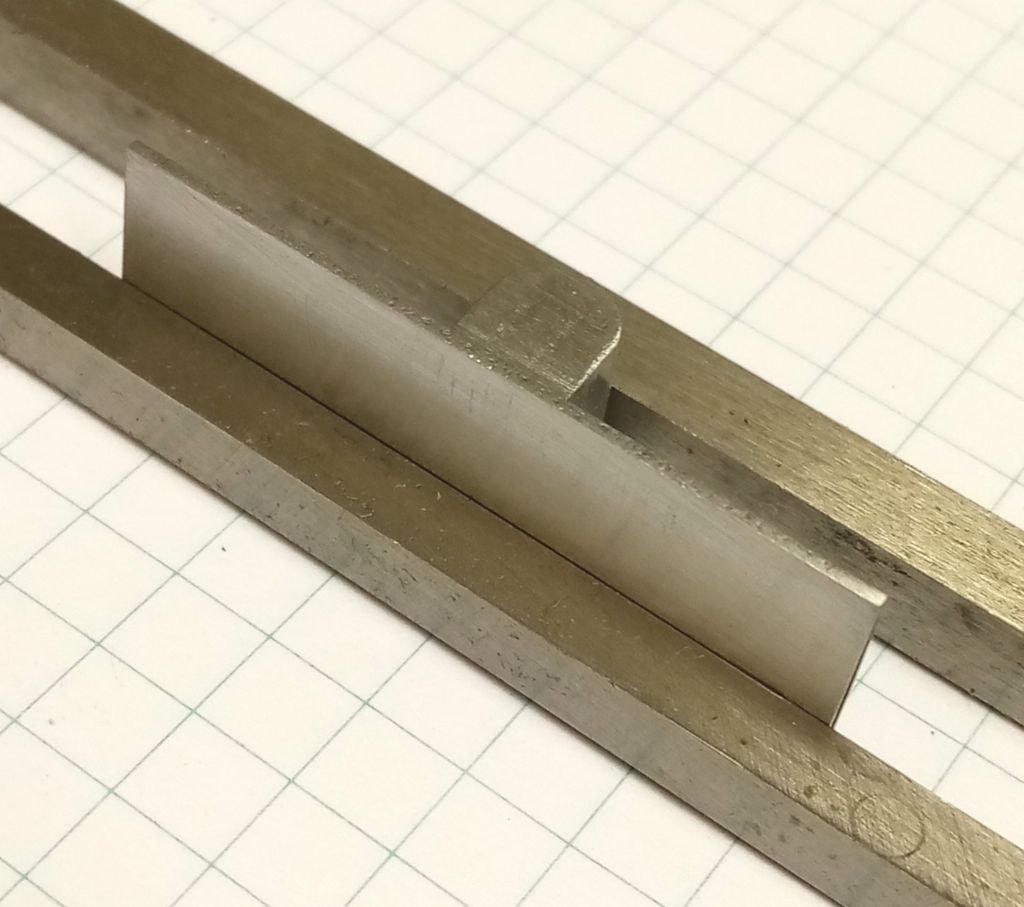

Cam Follower Fork

I did not have any 5mm square stock so milled down the end of a round bar and while in the indexer drilled and countersunk the 2.0mm hole then rotated it 90degrees and used a slitting saw to form the slot. Then into the lathe to drill 1.6mm and tap M2 before parting off to length.

Cam Follower pin

Another simple turning job, make sure the head is small enough to fit just below the surface of the Follower Fork.

You will also need a small dia spring to slip over the valve rod, about 20mm free length, 0.5mm wire. Does not need to be too strong as that will increase the load on the engine – just enough to keep the follower in contact with the cam

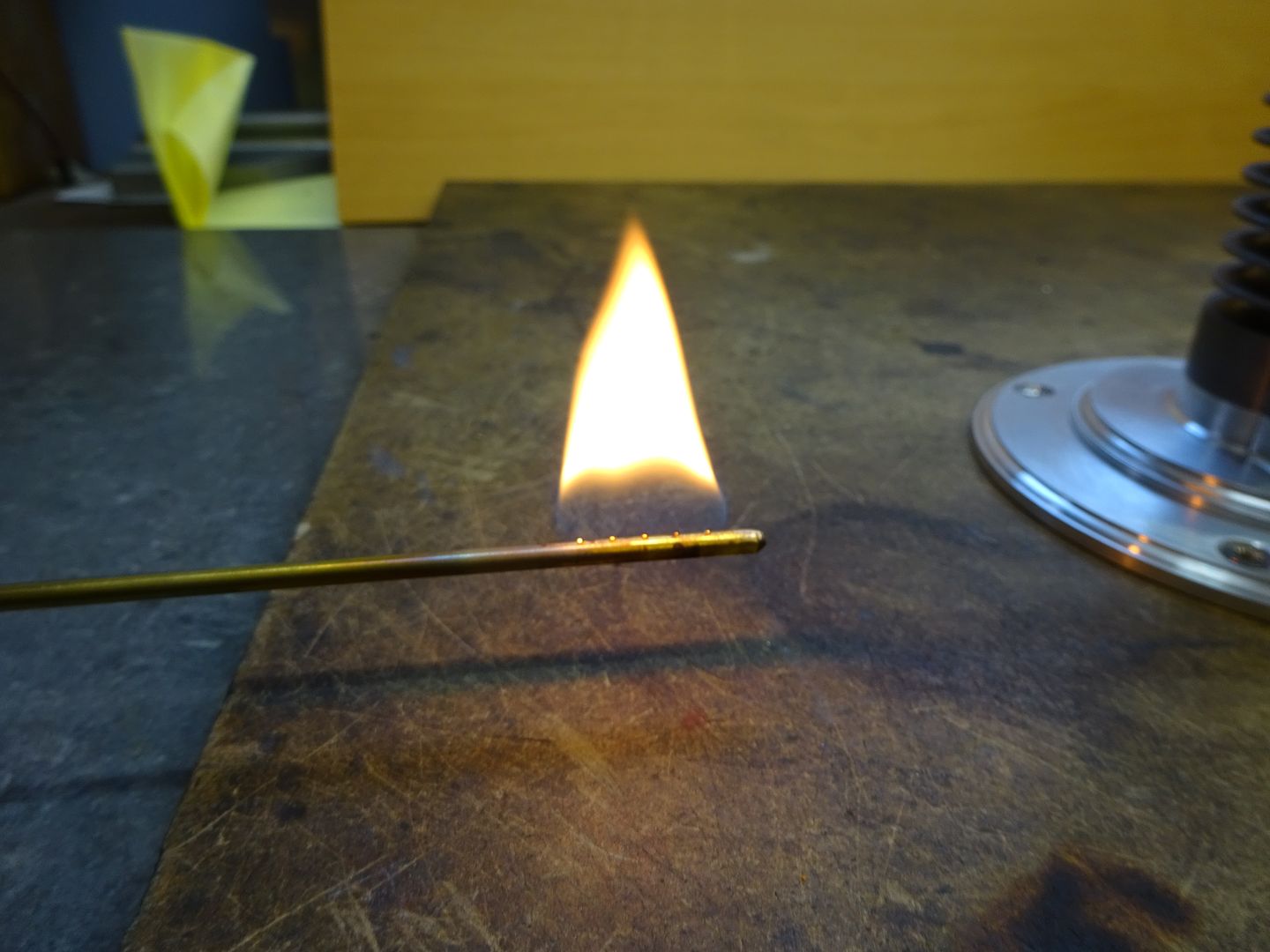

Valve

Face off the end of a piece of cast iron , turn OD down to 28.0mm and then part off a 0.5mm thick slice, if your parting tool leaves a pip in the middle don't remove it.

The eight sides that form the octagon can just be filed but make sure you leave a small part of the 28.0mm dia edge between each as it will help keep the valve centred within the base. The valve can then be lapped on some 1200g wet & dry using a disc of metal to keep it flat, this is where the pip helps.

Parting off will leave the valve slightly concave so you only need to lap the edge as can be seen by the polished area

Just the flywheel and burner parts left to deal with

J

JasonB.

JasonB.

holes at right angles to each other. Back into the lathe and drill and tap the M3 hole before parting off.

holes at right angles to each other. Back into the lathe and drill and tap the M3 hole before parting off.