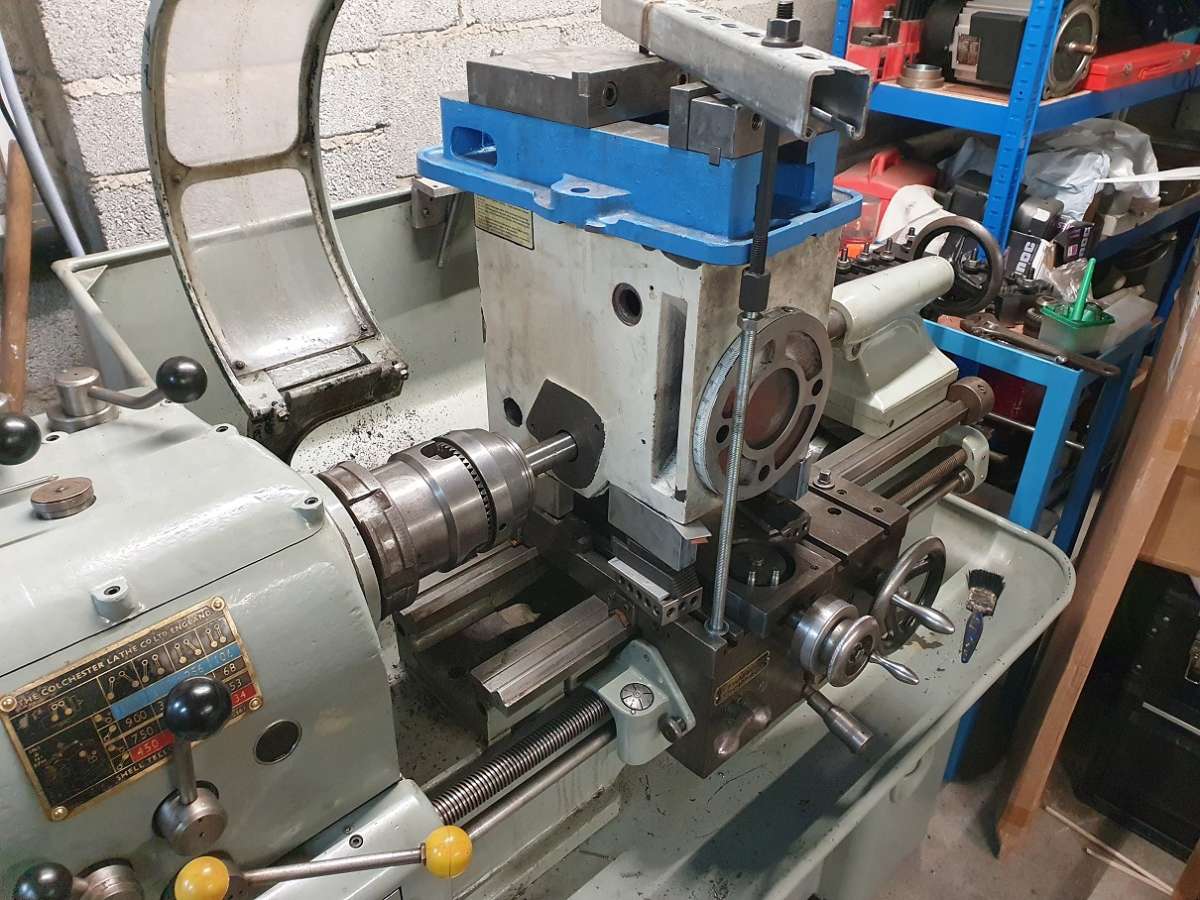

I’m liking this unistrut gantry hoist jobbie, with 1 and a bit hands I managed to get the base lifted onto my welding / work table so it’s easy to work on and and got the table mounted with no more than a gentle pull on a bit of thick string..!

Should have done it years ago.

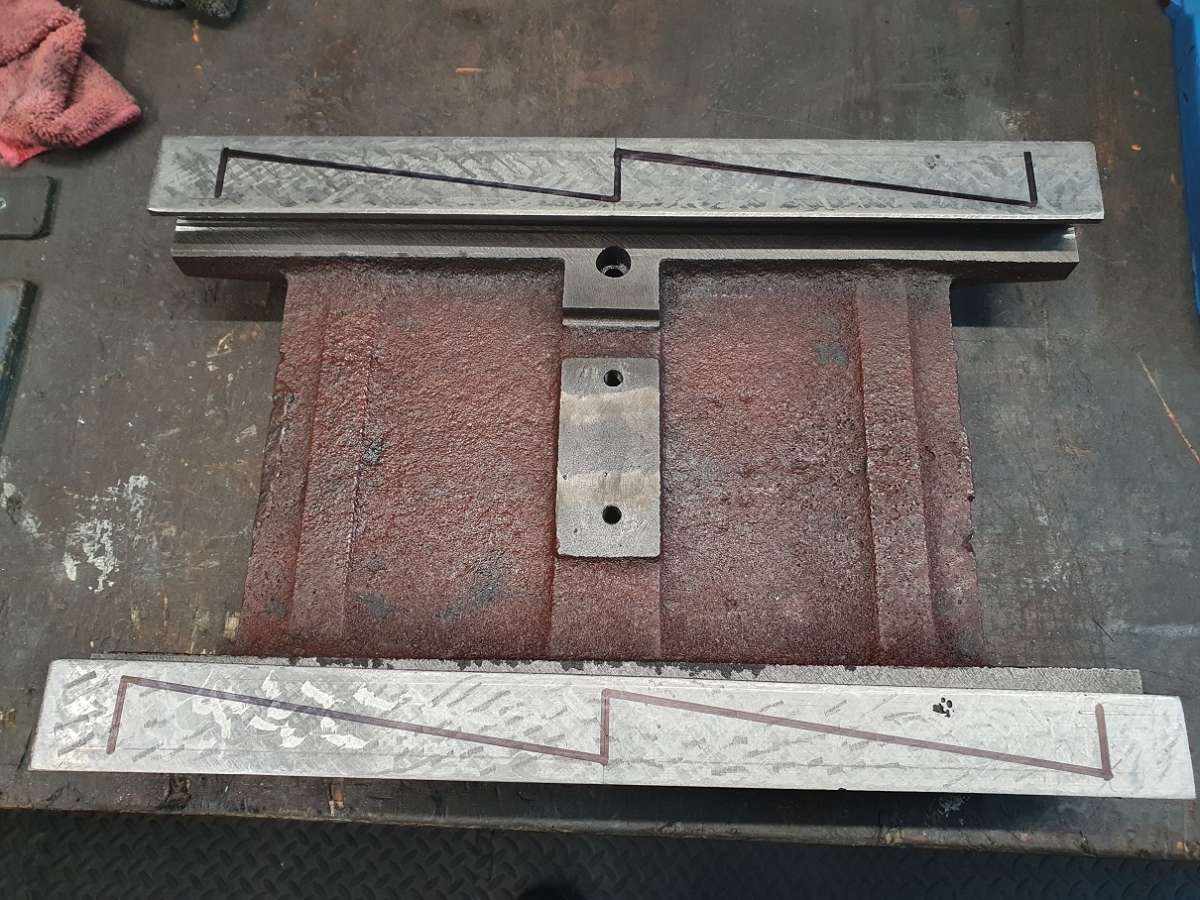

Anyway, cleaned up, some decent stoning of the dovetails etc then set up using pins in the dovetails and gauge block on the ways to rest the micrometer anvils on so all measurements are taken at exactly the same point on the pins. Basically the same way as doing the table dovetails so no need for a pic of that..

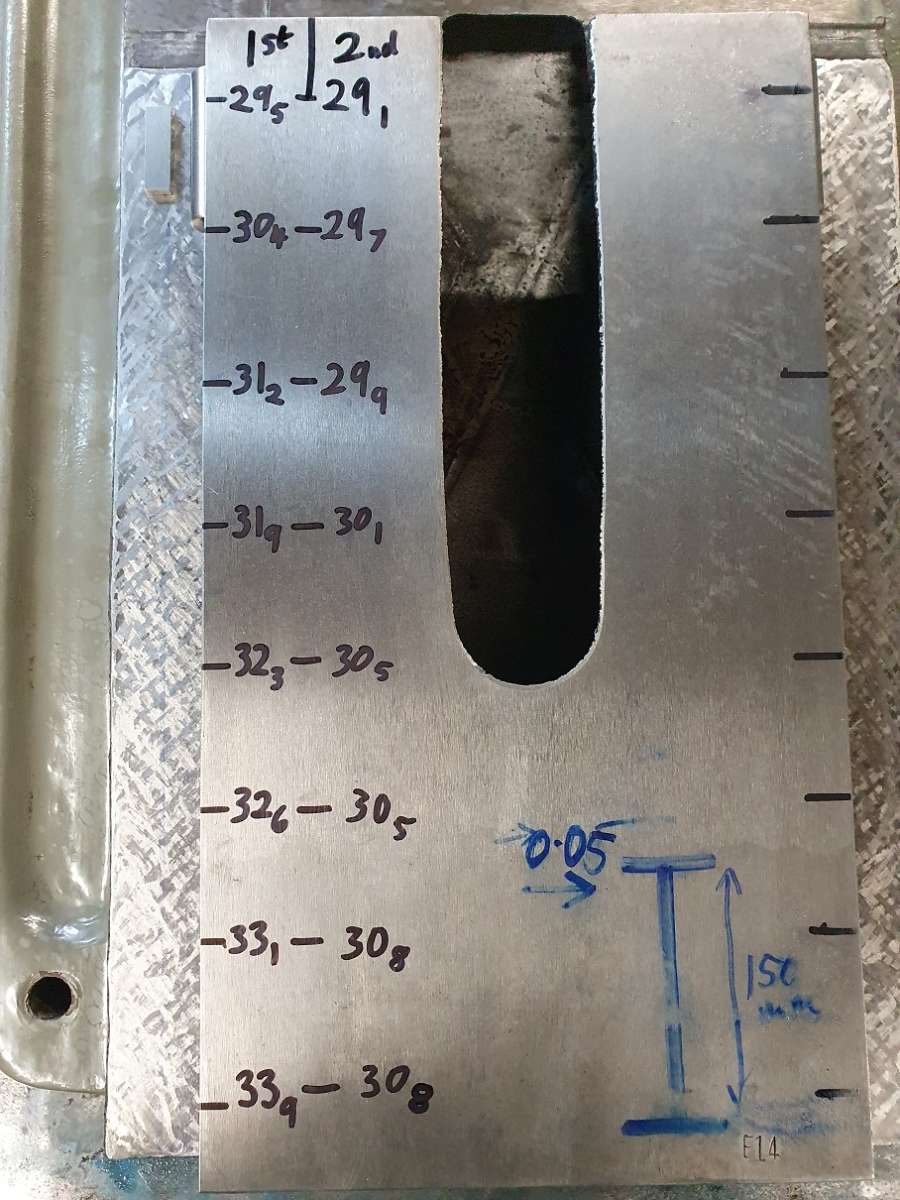

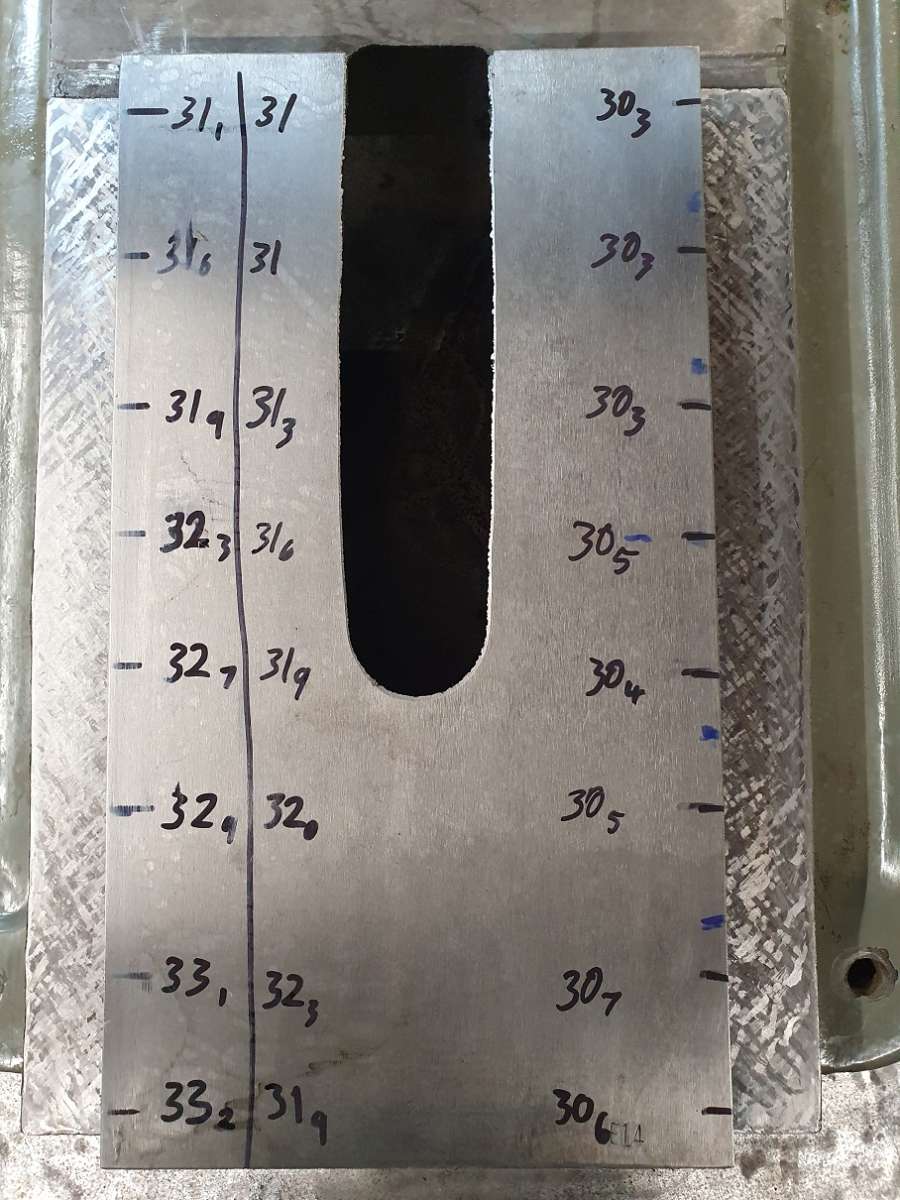

The result is –

The larger numbers are thou and the small ones are tenths. All were re taken 3 times so I’m happy they are good enough.

Pretty much 4 1/2 thou of taper between the dovetails. No wonder I could not adjust the gib!

Oh.. and apologies for working in mm and thou, I’ve always worked in either and I’m always flicking between the 2.. must be very confusing for those that just work in metric or in banana’s.. sorry!

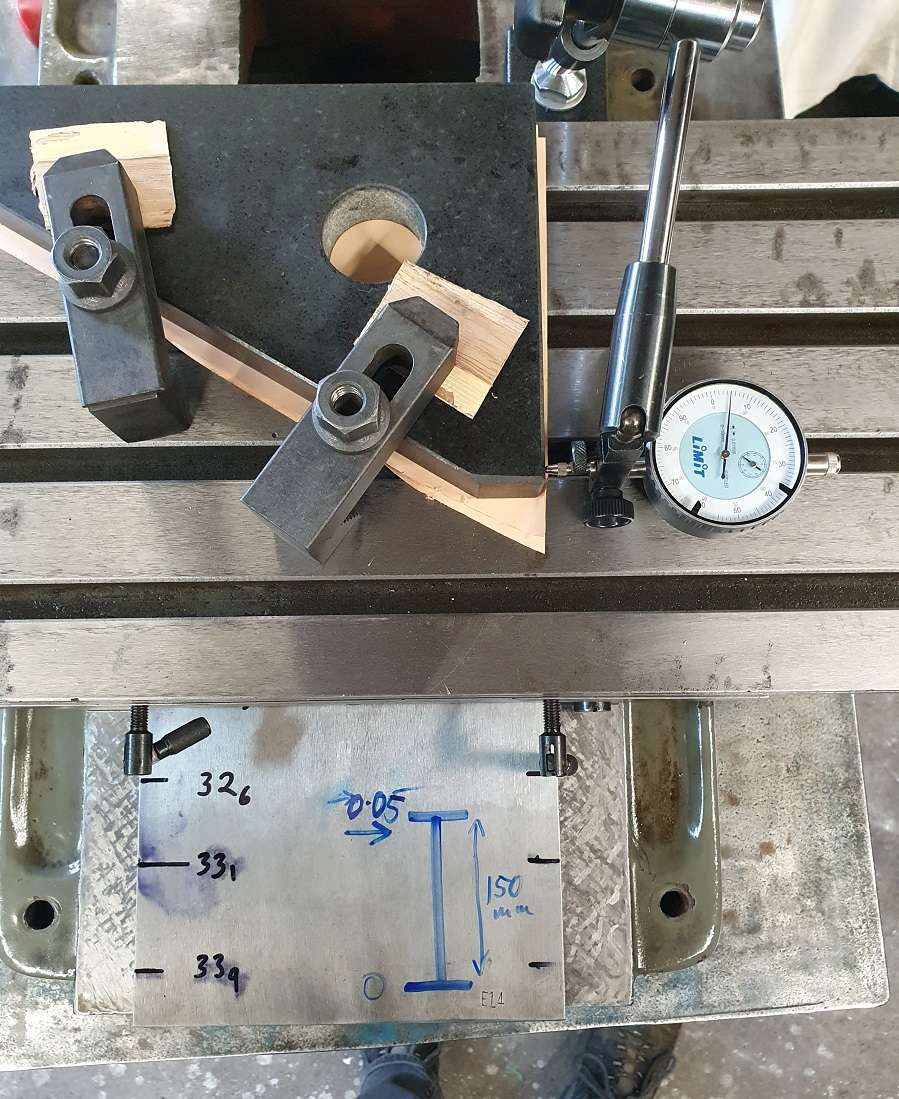

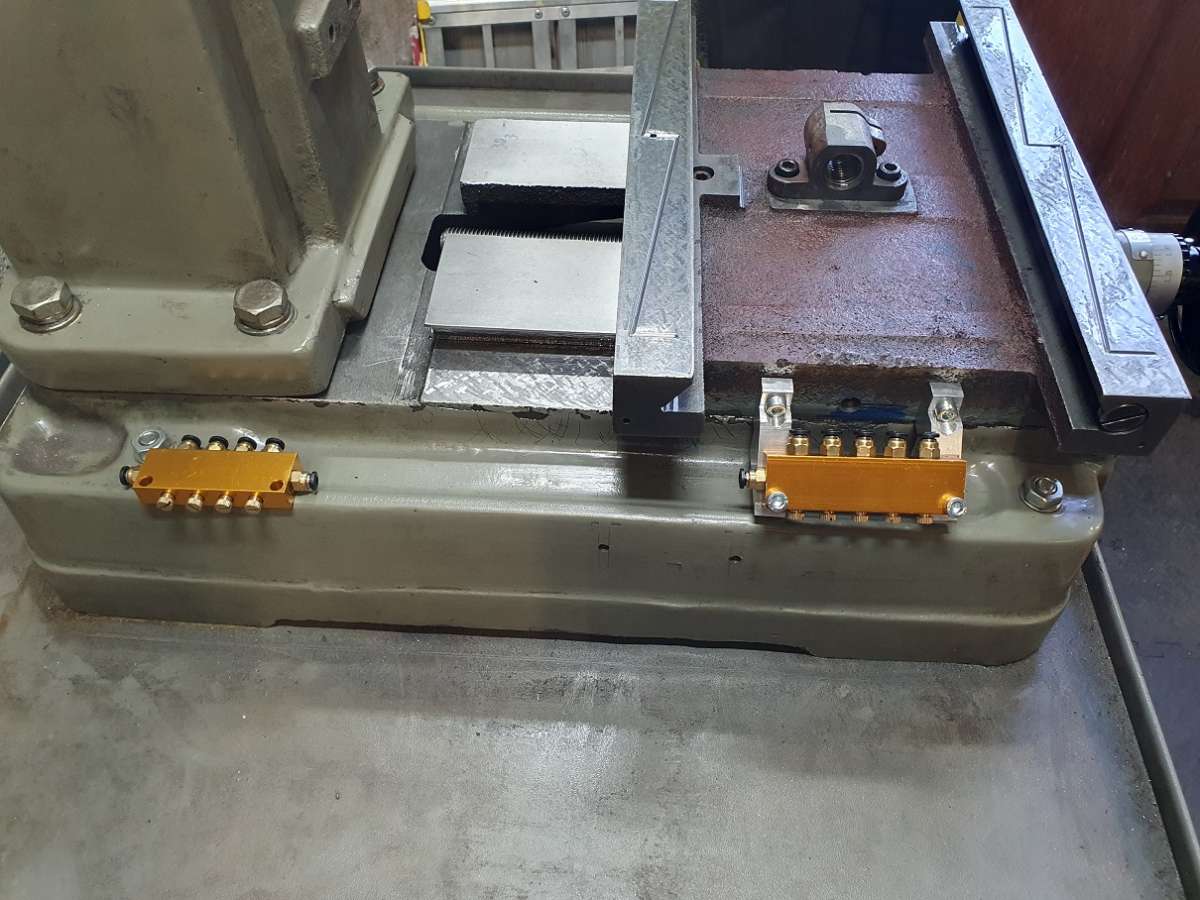

Then set up to properly check the X – Y relationship for squareness.

With the saddle right to the front in Y and the gib inserted as best as could be given the state of everything, the Y gib was locked.

Set the square true to X and recheck .. and again for good measure.

Lock X gib.

Transfer the indicator to the side of the square, loose the locks (indicator moved a fair bit) and move the table back the 150mm of the square. Re lock the gib so I am actually measuring the fixed dovetail side.

0.05mm difference so 2 thou near enough

Now I repeated this several times and always got the same result so happy enough with that.

What I failed to do was write down which way. I knew something had to make up for the table success, isn’t that the way it’s supposed to happen??

Jim Henson’s creations have got nothing on me. I’m blaming it on the nerve pain drugs personally, it’s like having a head full of cotton wool.

I’m pretty sure it was +0.05mm at the rear (the Y fixed dovetail side is the left side of the saddle and indicator is against the right side of square) so 2 thou to come off the front of the dovetail meaning 2 of my 4 1/2 thou taper will disappear.. but .. was it.. ? Oh dear.

Going to have to set up and do again to confirm before getting all ‘scrapey’ on it.

Anyway, some progress non the less !

Taf_Pembs.

Taf_Pembs.

Not ideal!!

Not ideal!!