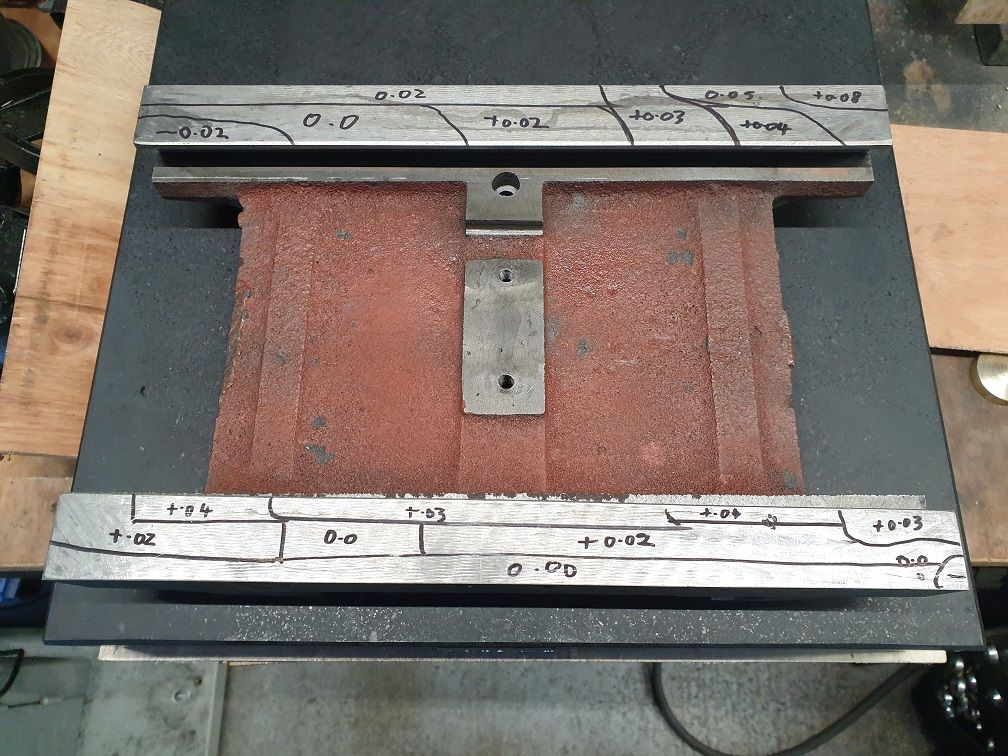

So next I set about trying to check the Table itself.

After much cleaning and stoning I placed it top down on the surface plate. Yes, it's far too long with a fair bit of over hang so crap for taking any measurements. I ended up placing weights in the centre in an attempt to counter the over hang and with only about 14lbs of weight the indicator readings on the ways became perfectly repeatable even when moving the table slightly left & right so with that being the best I was able to achieve it would have to do.

Both sides were out over their width, very slight slope of about 0.05mm although from centre out towards the ends was spot on along the rear way and the front way was good 1 way but tapered down to 0.05 low about 10 inches out the other.

After many .. many finger aching hours of scratching and stoning both sides are within 0.02 which considering the probable inaccuracy in measuring is way better than I could hope for.. leave it alone now!

Again, forgot the pic.. was so excited that repeated set ups gave consistent readings!

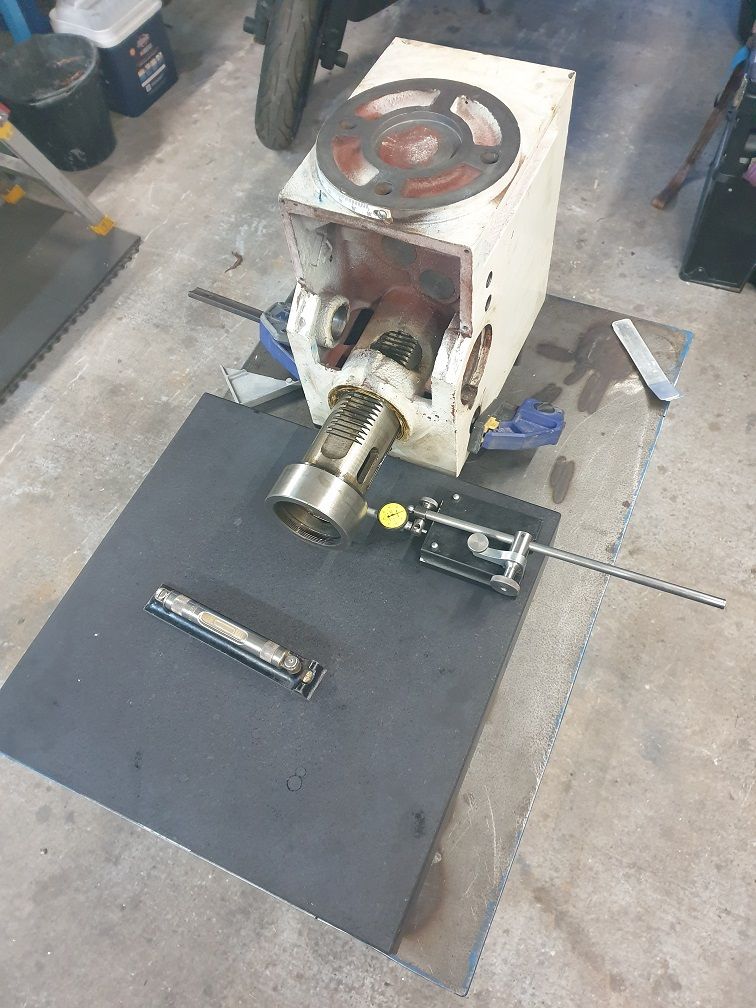

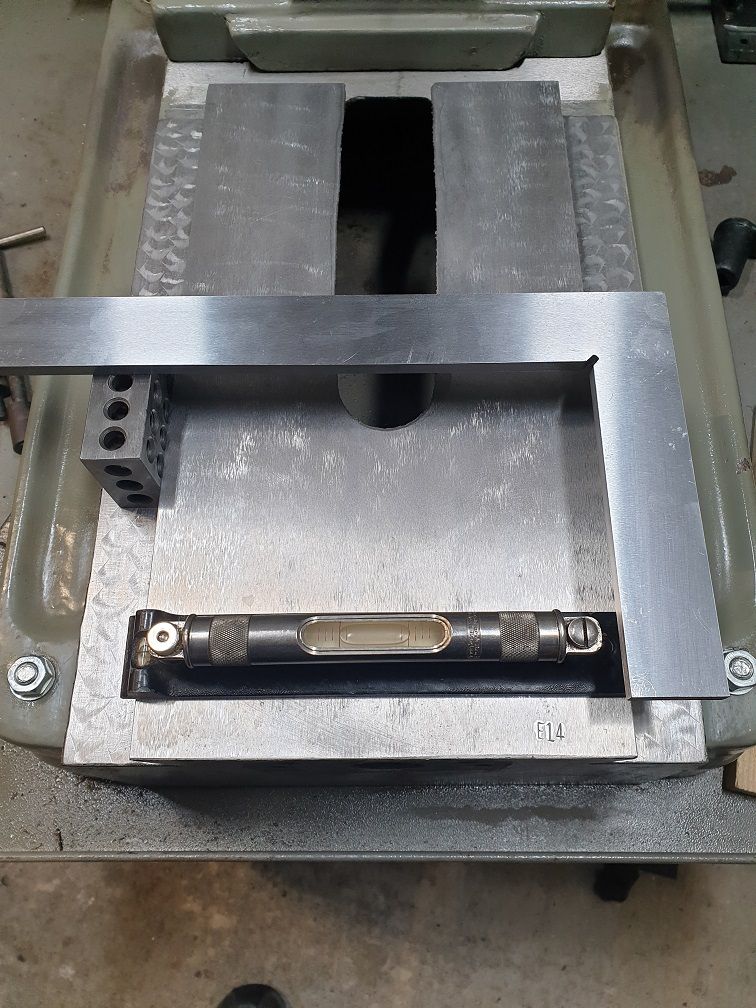

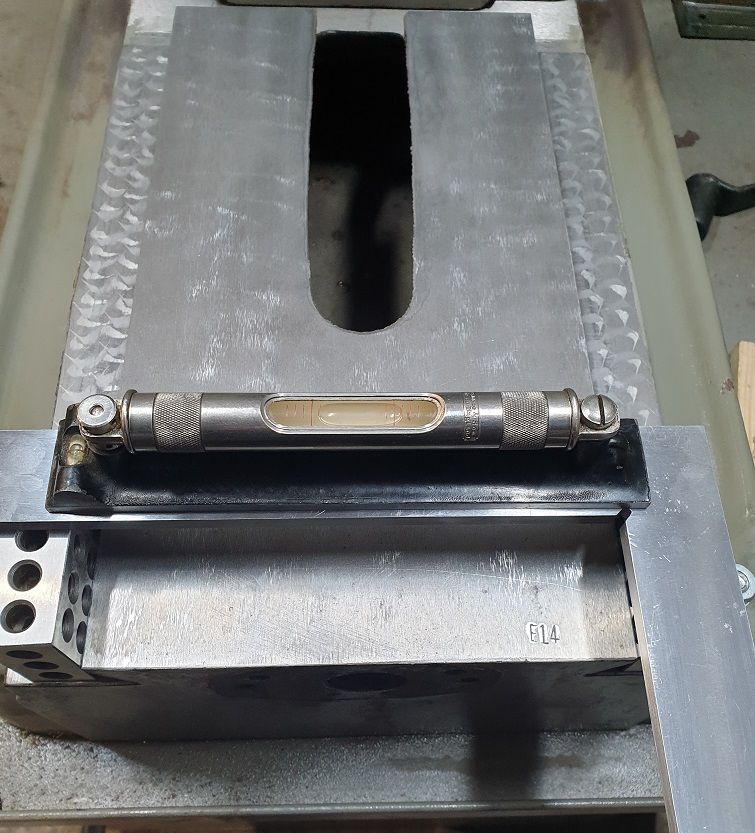

The Base ways.. cue a proper Heath Robinson set up but best I could come up with with what I had.

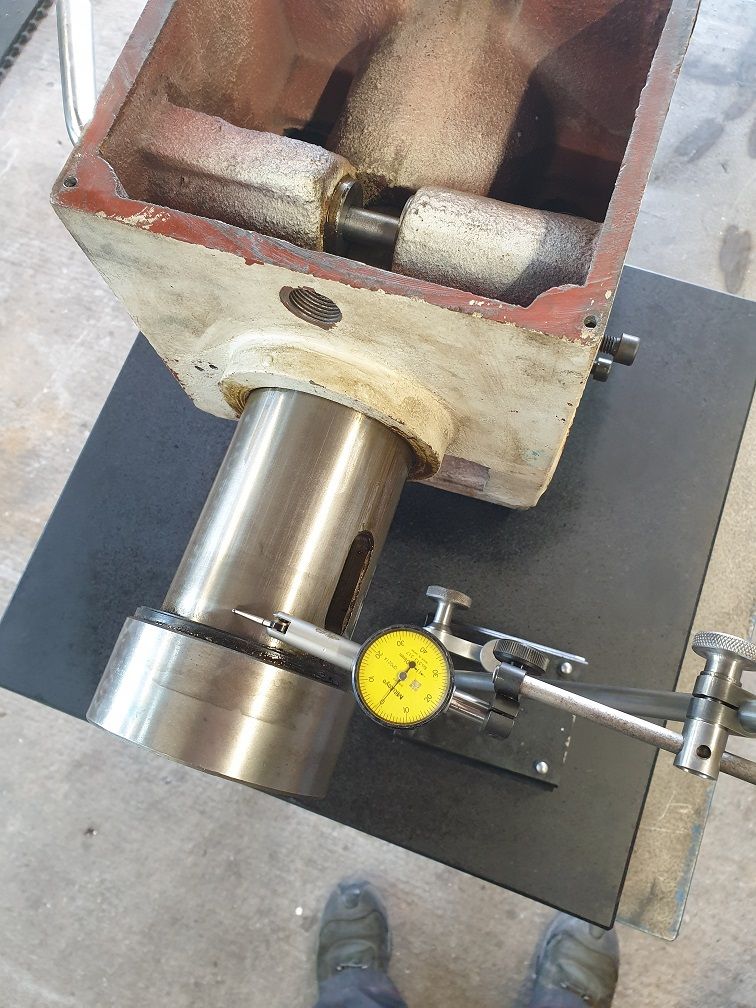

I used what appeared to be the ground face between the ways as I presume that is the reference surface for when they build the thing.

Put a machinist's level (as far as I can check it's a thou / foot, a J Rabone & Son's but no rating on it) on the freshly stoned surface and centred it with bubble just touching line on left.

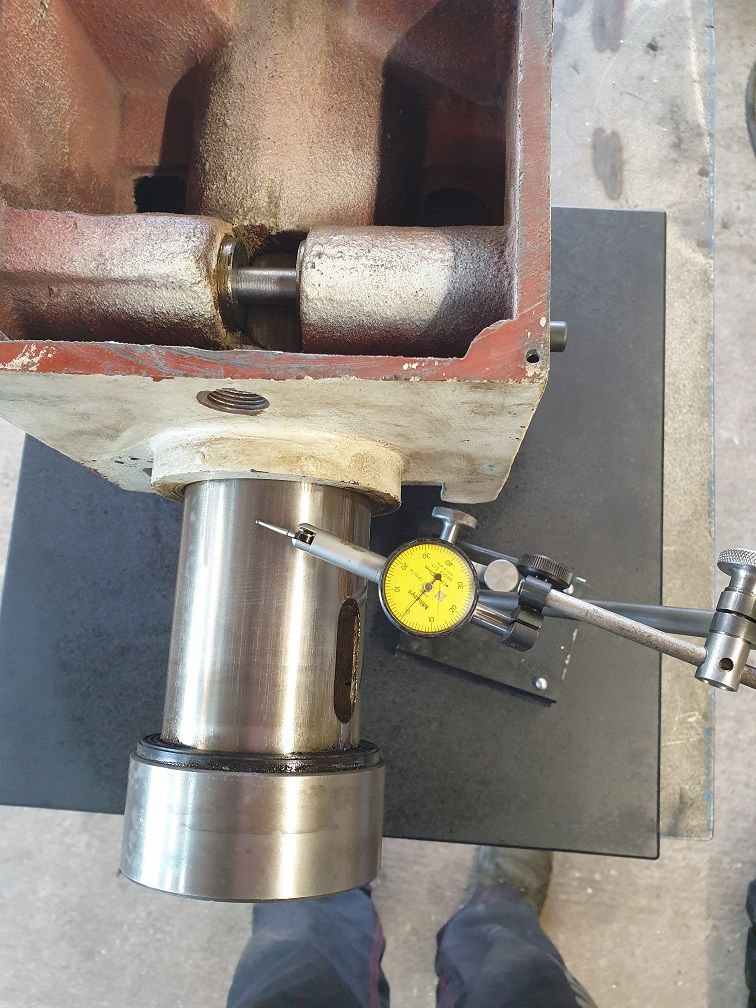

Then a pair of 123 blocks on each way and a so called precision square between (it was fairly cheap, not bad at all though) and the level on top. Moved along to 5 different positions down the ways with level and square positioned in same way on blocks each move.

Worst position was the 1 above, 1 division out . Here we go with the scratching and stoning again..

Managed to get it so the rear half is bob on and just less than half a division on the level out at the front.

All things considered I think that will be good enough but I may have another attempt at because I know it's not quite there..

Think I deserve a pint now although I'll probably drop the bugger the fingers are aching so much!

Taf_Pembs.

Taf_Pembs.