With my apologies for resurrecting this old thread, but I have just ordered the drawings and construction notes for this kit from Hemingway's, having temporarily run out of ideas for new tooling and reinventing the wheel. It would appear that the promised video never did appear for whatever reason and I am aware that there is another thread on here started by Keith Beaumont, but it has been made disjointed by the removal of posts by another member. I won't pursue that; it's been covered ad nauseam in another recent thread.

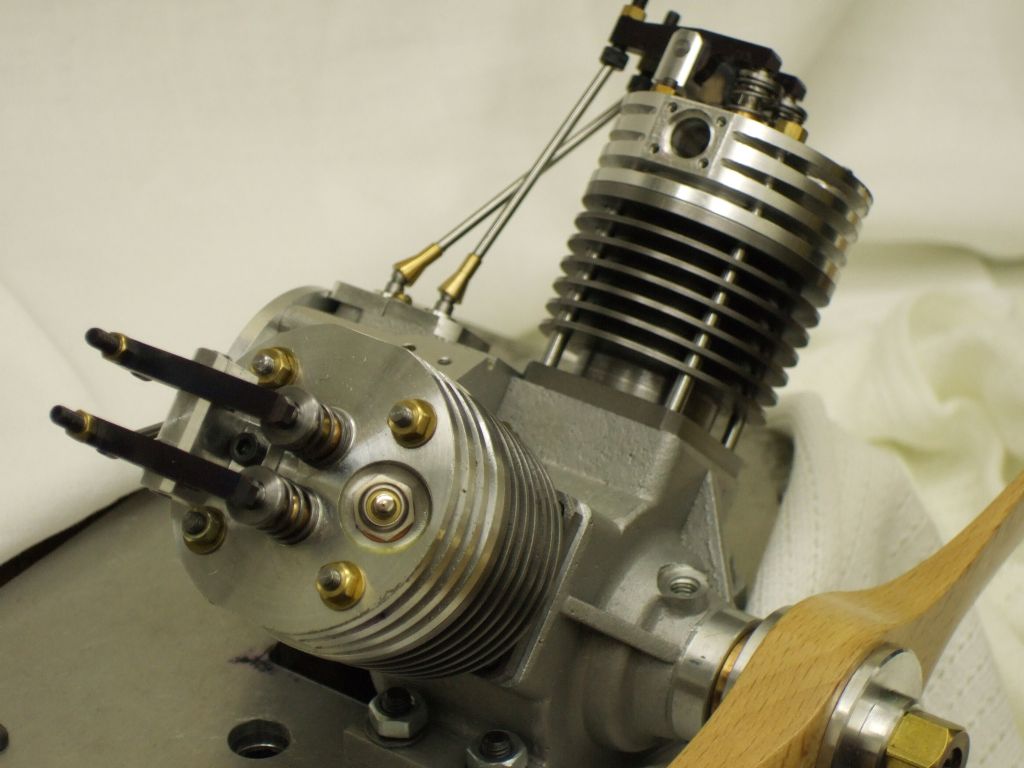

My reason for posting is that, reading various reports on getting the motor to run and remain running seems to have thrown up an issue with the induction system. I intend to separate the induction to each cylinder and make a pair of carburettors after the style of the Amal ones. If that has been done before at this scale, I'd be interested to be pointed in that direction.

Also, if anybody else has made the engine, I would likewise be interested to hear their experiences (good or bad).

I might add that I intend using electronic ignition instead of glow plugs and will investigate the possibility of a pressurised lubrication system. On the cards is a 3D model, too, if I can manage to reproduce the castings to an acceptable degree of accuracy.

John

John Hinkley.

John Hinkley.