I've been having a discussion via PMs on grinding Coventry diehead chasers. As well as grinding the throat the front of each die needs grinding. This is because the threads are not radial to the work but cross the axis at an angle. This is so the cutting is done up to,and including, the first full tooth, the rest acting as a guide.

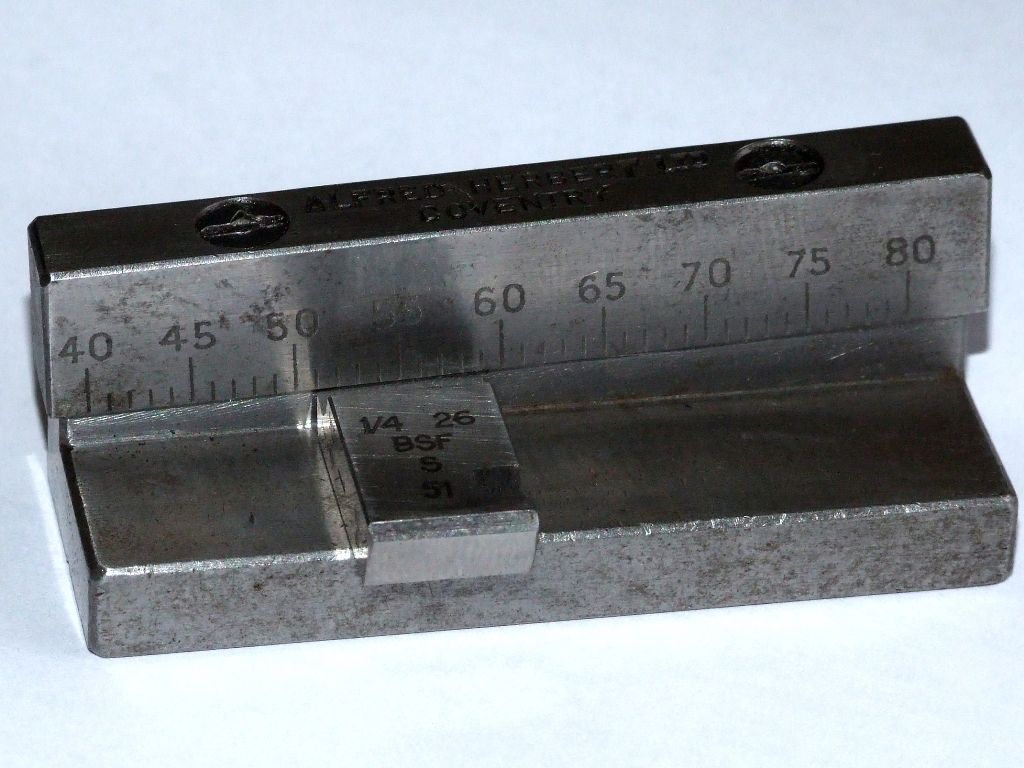

To help grinding the front face each set of chasers has an arbitrary number on it, which has to be matched against a tapered rule. Here's a picture of one for ½" RH chasers, the key number for this chaser set is 51:

The numbers seem to increase linearly with diehead size, so in theory one long rule would cover all dieheads. I've measured the angle as between 2.6° and 2.7° across several rules. Unfortunately these items seem to pretty rare; probably because a toolroom would have had only one set to cover multiple dieheads. They come in assorted sizes, for different size dieheads, and RH and LH are different. I can't remember where mine came from, but probably mostly Ebay.

Andrew

lug lord.

to look at .It seems the more i do is like a chain reaction need this for that and that for this it seems to never end . I can see now why i need a surface grinder to keep all the angles the same .

to look at .It seems the more i do is like a chain reaction need this for that and that for this it seems to never end . I can see now why i need a surface grinder to keep all the angles the same .