Posted by Neil Wyatt on 24/05/2014 15:11:55:

I often use a parting tool with the toolpost turned at 45 degrees. Unlike many tool shapes the cutting edge is flat so you get a true surface. It's much quicker than turning the topslide.

Neil

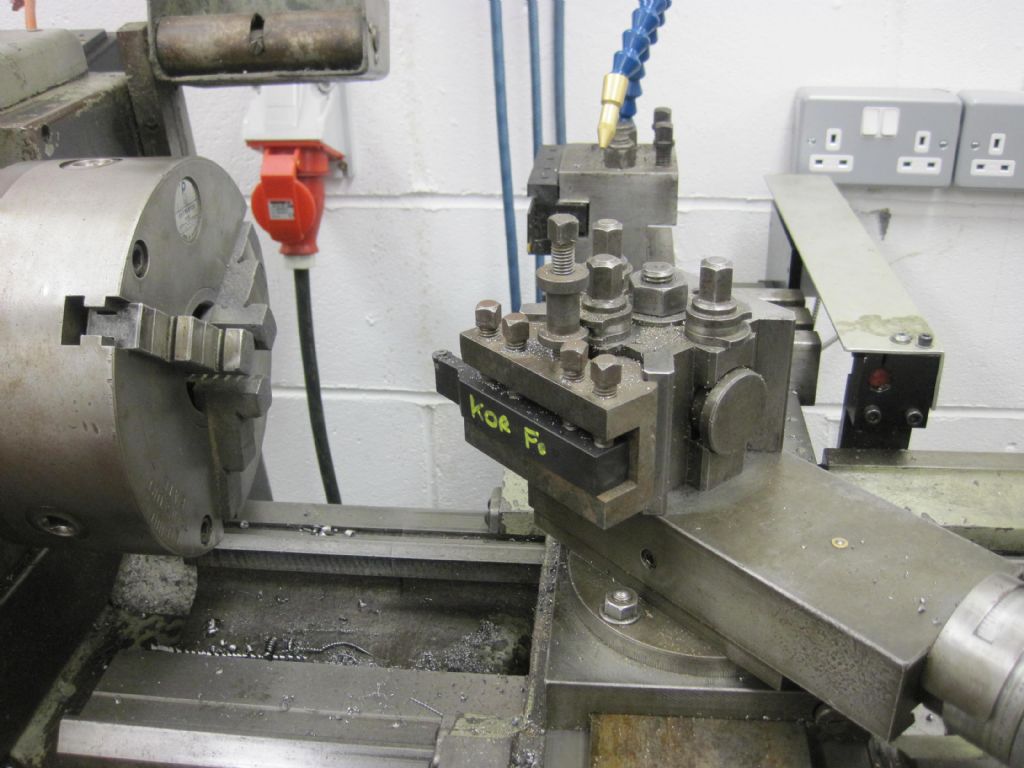

Although this can work well turning the tool post and, for that matter the top slide, is a thing to be avoided if at all possible. Yes it does help you get more use out of a tool by pressing it into service to do jobs it wasn't specifically designed for but at the cost of needing to reset back to for normal afterwards. Possibly an acceptable process if you use a rear toolpost for parting or if you have a good indexing base for your four way or QC set-up so as to get things back to parallel automatically. Setting things exactly at 90° for parting off is essentially impossible mid-job with work in progress mounted up unless you have some clever way of gauging things.

Accurate angles belong on the tool not the mounting. The extra cost and mostly one time trouble of arranging a set of tools such that you don't have to routinely shift top slide and/or tool post angles is well repaid by the time saved and better cutting performance got from optimising around one set of working conditions. Shop time is a precious, limited, resource not to be wasted by repeated resetting.

Clive

Ian S C.