Posted by Paul Lousick on 27/04/2020 00:00:21:

Can we have a servey of what people use ?

I rarely mark out and centre pop. In general only for sheet metalwork where I'll be using a hand drill. For probably 80% of my drilling on flat surfaces I don't use anything, just drill direct with a 4-facet drill. For holes up to about 8mm I use one drill, no point in faffing about going up in small steps.

I have 2, 3, 6 and 10mm 90° carbide spot drills. I use them in three circumstances. One, for non-flat, mostly round, surfaces. Two, for rough (cast) surfaces or three, where I want more accurate location of the holes.

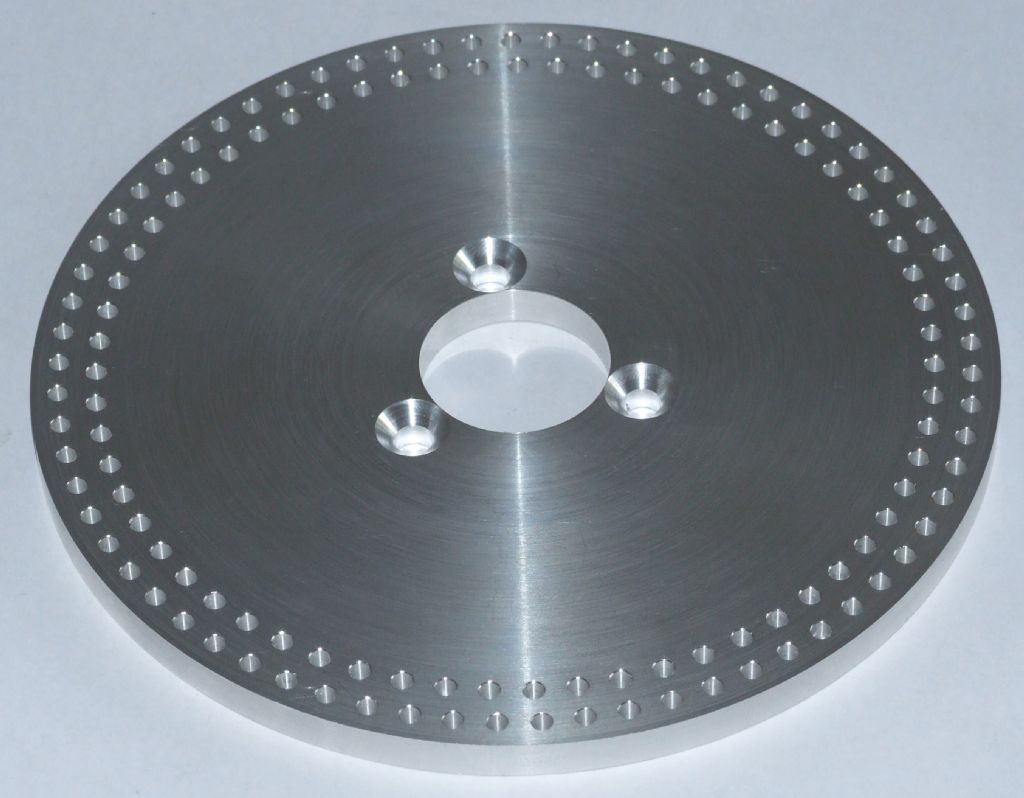

I don't know what accuracy I achieve by spot drilling first, but anecdotally probably a thou or two. When I made this differential consisting of two ring gears and a centre casting:

I drilled the circle of holes holding the assembly together by spotting and then drilling. Unfortunately I had the centre back to front.  I turned it over and all the holes still lined up perfectly. I drill 6mm for a 6mm bolt, so I estimate my location accuracy must have been a thou or two.

I turned it over and all the holes still lined up perfectly. I drill 6mm for a 6mm bolt, so I estimate my location accuracy must have been a thou or two.

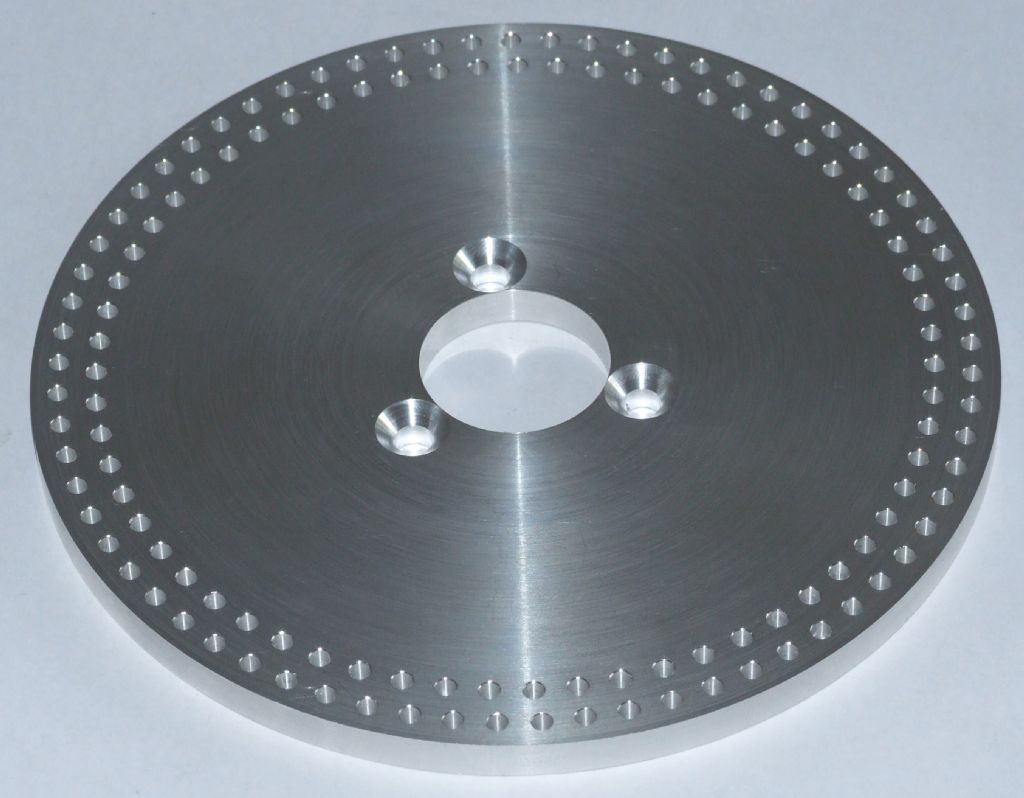

The last time I used a centre drill before a twist drill was on this special dividing head plate:

And that was primarily because the existing countersunk screws had 60° included heads.

Ideally I'd do some experiments, but even in lockdown, with no work available, I seem to be busier than ever and the round tuit list is expanding exponentially.

Andrew

Edited By Andrew Johnston on 27/04/2020 11:28:31

Stewart Wells.