Bonjour

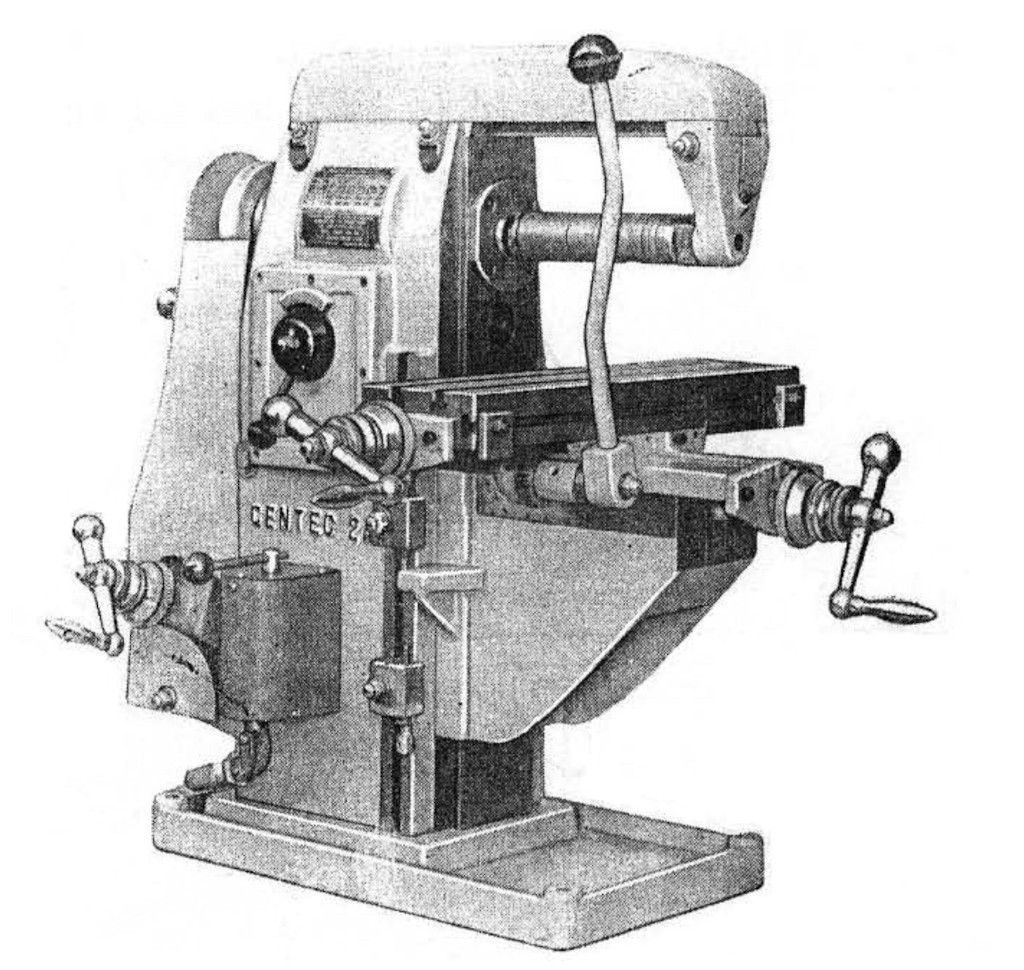

Going to resurrect this thread for a basically identical issue – except the knee casting of my Centec 2 has extra iron between the two webs seen on Sean's machine. Good for rigidity, bad for having a clear space to stick a leadscrew and gearbox and handle and so on in. I'm missing the original handle but otherwise the rack and pinion still functions.

Thinking about working within the limits of the existing set up I don't like that 1) the stop screws aren't graduated 2) if you have to move the knee further than the travel of the screw you have to move the entire stop, thus losing your measurement, 3) if you let go of the lever and the position stop / gib lock isn't tight then the knee will fall down

1) -> replace the screws with micrometer barrels, though I do wonder about the durability of them. Doing repeat cutting passes would get boring fast with no way to switch between precise adjustment and rapid approximate cuts as on a leadscrew dial.

2) -> replace the screws with extra long micrometer barrels? This one I haven't properly worked out yet.

3) -> A mystery to fix. Counterbalancing the knee with a gas spring would help. A switch attached to the handle which actuates a form of lock/clamp would be nice but I can't yet think of a mechanism

If anyone has ideas or has solved this on their own Centec then I'd like to hear them.

Also if anyone has a centec handle for sale I'd be interested, trying to work out that taper and cut a square hole is possible but maybe a bit tedious.

Dave Halford.

Dave Halford.