Posted by Chris Gunn on 29/01/2019 19:38:43:

Bill thanks a lot for the Centec manual link, I have just acquired 2 machines, 1 is a 2A horizontal, the other is a 2B with a vertical head and power feed, all on the big base with drip tray. I will have to see what they are like and decide which one to keep. They are both 3ph, 380v so I will need to change the motors. Would you happen to know if the power feed motor is a standard frame size?

Chris Gunn

Chris, in my case I run the main motor off an inverter, but the table power feed motor was, like yours, a 415v one with no accessible star point, and I didn't have a suitable inverter available.

At the time I was converting it, I had a broken leg, so going shopping for big heavy bits was a bit tricky.

At the moment I've got a normal single phase motor as the table feed, but it's not ideal for at least 3 reasons.

It's bigger and heavier than the original, for a similar horse power output, so with the table travel at max to the right, there is a noticeable tilt on the table; not a lot, but enough.

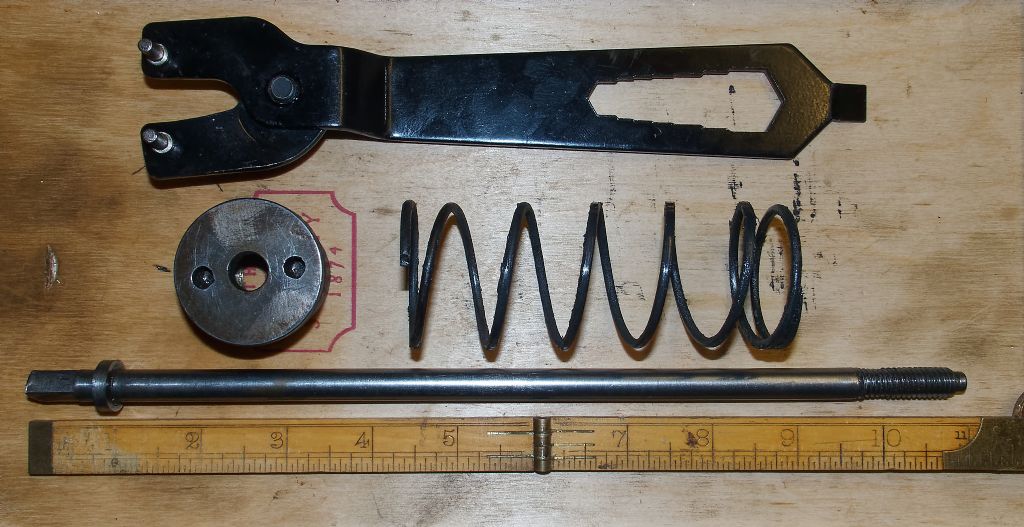

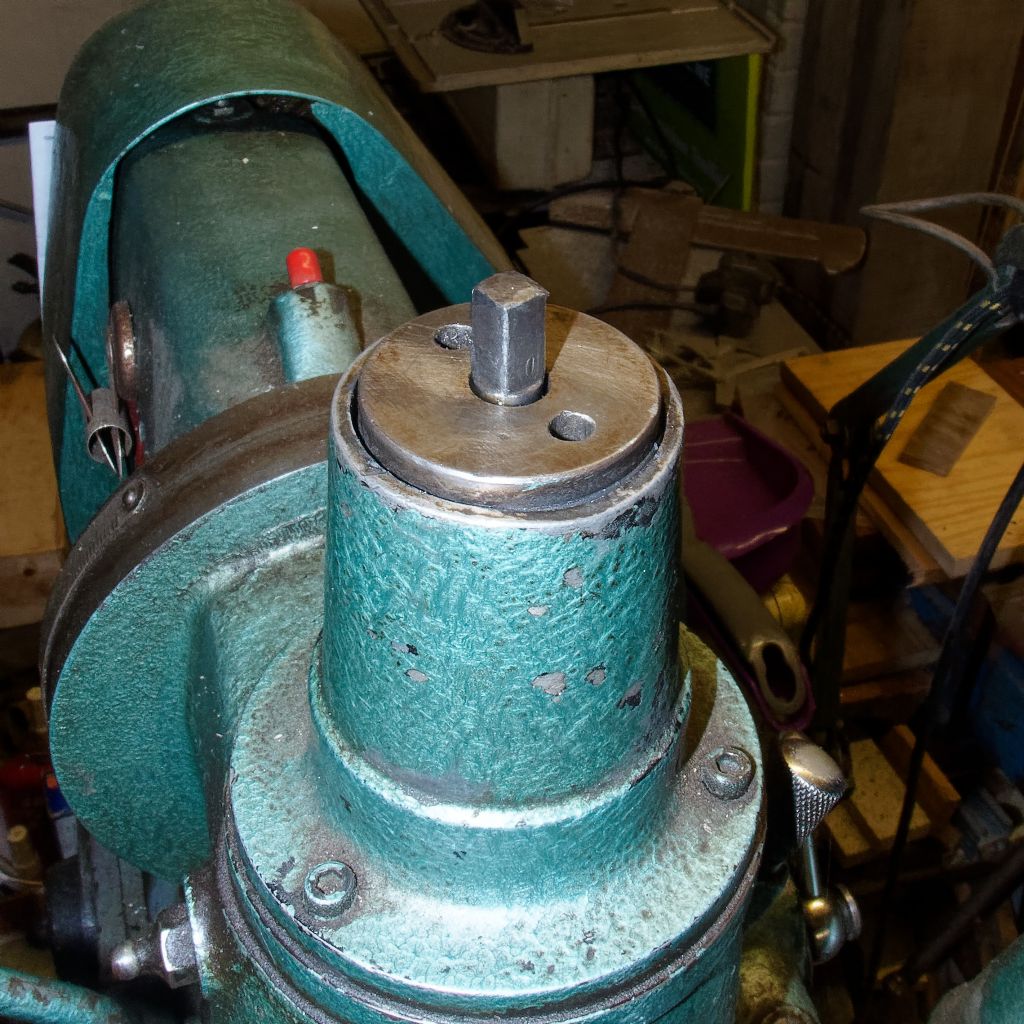

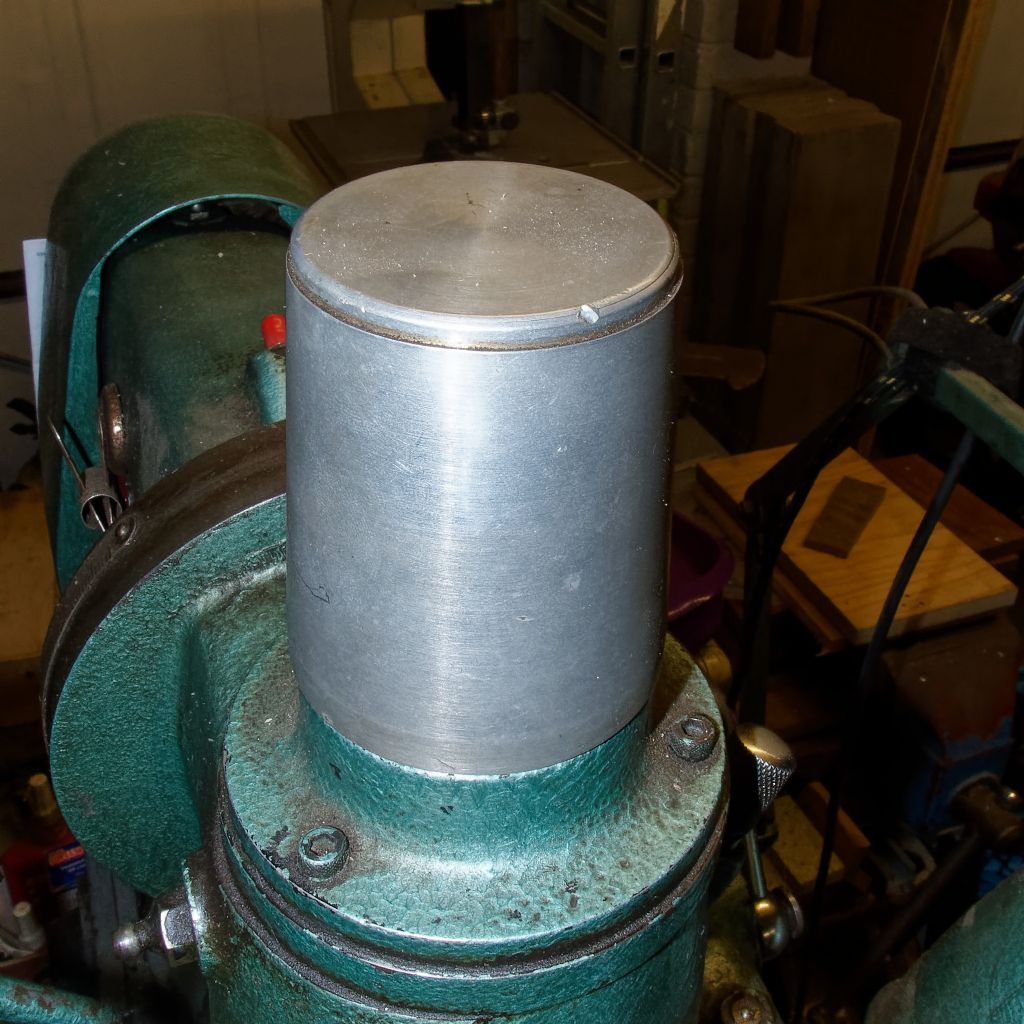

Also to get a different motor to fit, it clearly has to be a flange motor, but the actual output spindle needs turning down with a couple of steps and a through hole for a pin.

Gary Wooding on here has dived in and found the star point and re-wired his machine accordingly, so it runs off an inverter, See the photos in His Album

Personally, with the price of inverters being as low as they are at the moment, I'd not change the motors.

Swapping out the power feed one has certainly caused me some issues, and I intend to revert to the original when I get the time, either by doing the same as Mr Wooding, or by using one of the newer Far Eastern inverters with the 415V output.

Bill

Edited By peak4 on 29/01/2019 20:02:16

not done it yet.