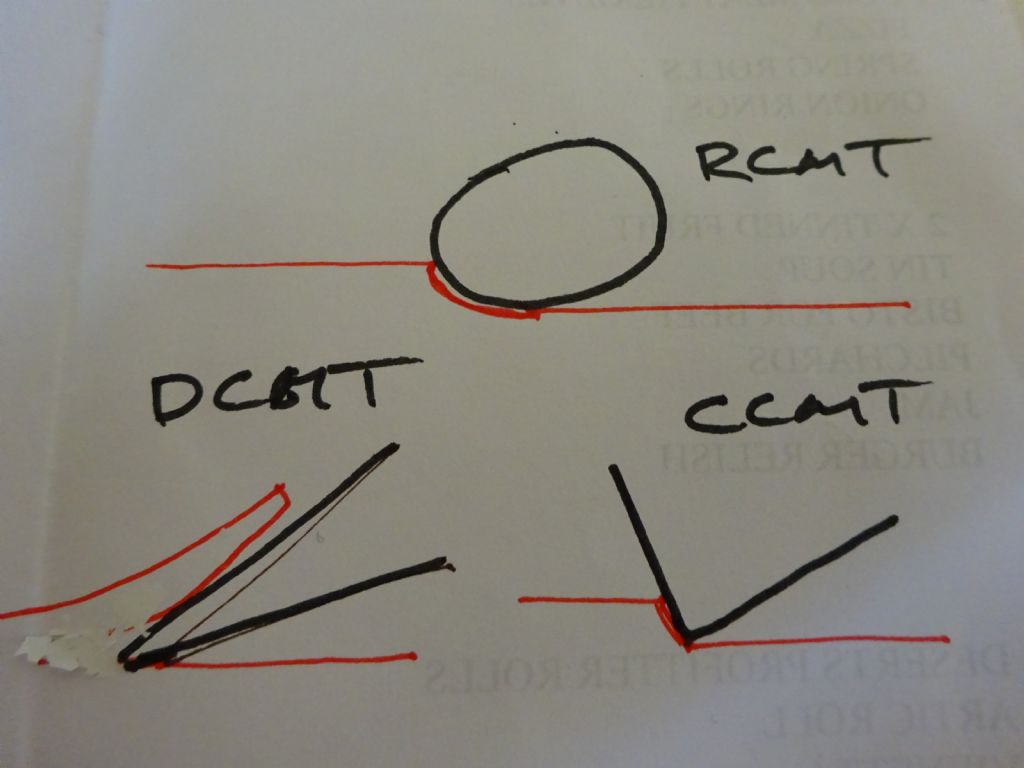

I should have posted this here I guess, just to say what I did as a result of the advice given (it's also in another thread). I got a selection of 4 types of insert from Cutwel. Ordered 16:30 yesterday, arrived this morning. DCMT, DCGT, 0.2mm and 0.8mm nose radius, some for cast iron, some for non-ferrous and others for steel. There was an online chat thing, so I was able to confirm I was getting the best inserts for my tools and what I wanted to do:

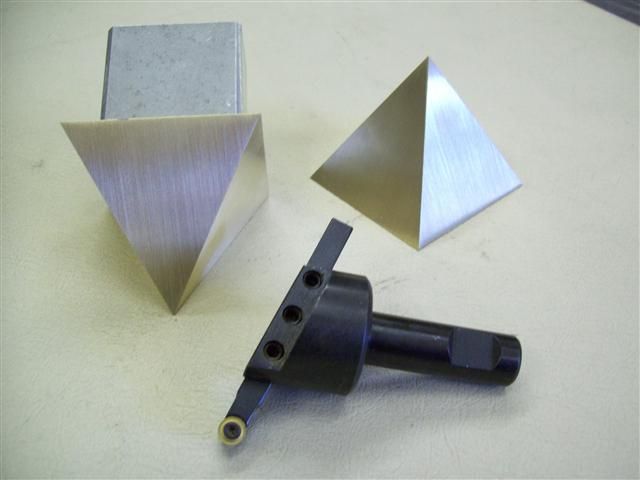

So the small fly cutter holder arrived today. I put my Sandvik 8mm left hand tool holder in it, fitted with a DCMT 070208 insert for steel, and had a go at fly cutting for the first time. Must say I was really happy with the results, finally a bit of progress. Workpiece was the same mild steel I've been using for the vice clamps. I went up to 0.5 mm cut depth with no issues.

The only slight problem was vibration due to the tool holder being long. I ground it down a bit and that resolved that. The grub screws in the holder appear to be made of cheese, so having got the tool well and truly stuck, I spent a good 30 minutes drilling them out and replacing with caphead screws, which was fun.

Missed the postman due to work, so the milling cutter test will have to wait, but in the meantime, for the 10V castings, what do folks recommend for facing: milling or fly cutting? I did get some DCMT070208 inserts for iron too.

Thanks.

As an addendum to this, I'm a bit unsure as to feed rates and spindle speeds. Pretty much everything within reason worked without any complaint from the machine. I got the impression I might have been running at too high an rpm though, becasue the chips appear to be blued by heat.

Still, I faced my remaining vice blocks, and got much better surface finish than milling, and parallel over 25mm x 40mm to within 0.0006" according to a my micrometer, over an average of 5 measurements. Sorry to mix units!

Chris George.

![20200511_090735[1].jpg 20200511_090735[1].jpg](/wp-content/uploads/sites/4/images/member_albums/44290/861548.jpg)