All,

Many years ago I was given some Sandvik 8mm carbide tool holders and inserts. I'm now pretty much out of inserts, and initially wanted Sandvik again. The prices are daft, so I sourced some from Chronos.

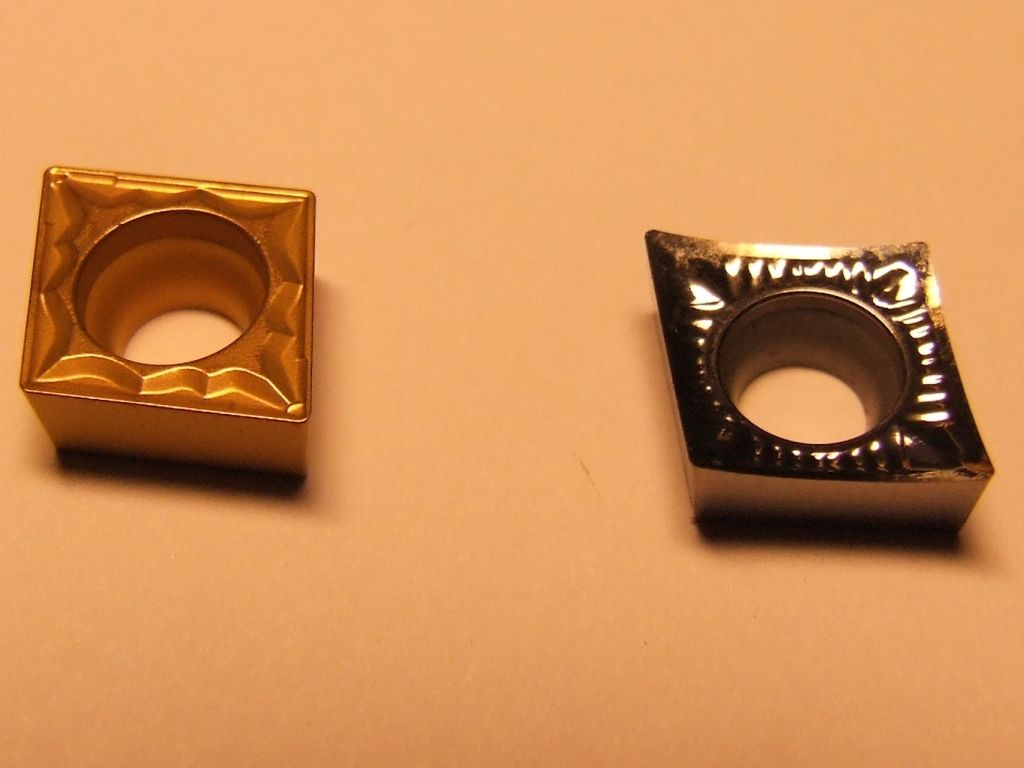

The original Sandvik inserts were DCMT 07 02 04 PF.

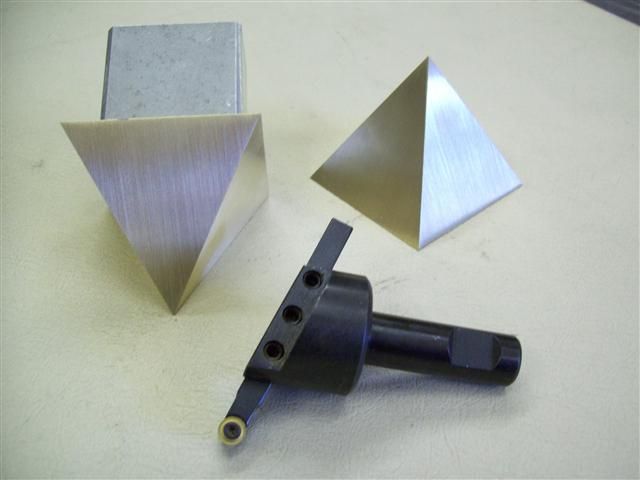

Having de-coded this, I think they were suitable for fine work on model engineering type work, however, today I've been turning some small top-hat bushes and shims for a rc model car. It occurred to me that the nose radius of the inserts was a bit big for this type of job, where I wanted a sharp internal corner on the inside of the bush overhang. I believe it is 0.4mm. Normally I'd have chamfered the mating part external corner to 0.5mm x 45 or something, but I couldn't get access in this case.

Question: The Chronos product code for their inserts was DCMT070204. There was no option to choose other options, so I'm guessing it's a 0.4mm nose radius again. Where can I get reasonably priced DCMT inserts and specify the nose radius? Or, as ever, any other comments on what I'm doing and how I'm doing it are welcome.

Thanks.

ETA: For scale, the larger OD of the top hats was 7mm.

Edited By Dr_GMJN on 09/05/2020 21:30:33

Chris George.

![20200510_122403[1].jpg 20200510_122403[1].jpg](/wp-content/uploads/sites/4/images/member_albums/44290/861386.jpg)