Posted by felis concolor on 25/12/2021 18:12:26:

… there is nothing here in Canada for Myford-specific rear tool posts.

Which brings me to…..which brand / make / design is a quality tool, proven to work well?

…

One more consideration relative to a parting tool holder…..do you guys prefer carbide insert parting blades or hss blades? Again, this is for the capabilities and limitations of the ML7.

…

Another vote for Carbide mounted in a rear tool-post.

Bee in my bonnet I'm afraid, but I dislike 'quality' used as a requirement because the word's meaningless! I prefer to think in terms of 'value for money' and 'fit for purpose'.

The problem with parting off on small lathes is lack of rigidity. The cutter puts a lot of force into the tool-holder, causing it, the tool-post and the saddle to twist and tilt. Not much movement results in a dig-in. Much easier to part off on big heavy lathes than small ones, however well-made the small lathe is. Big lathes are more rigid.

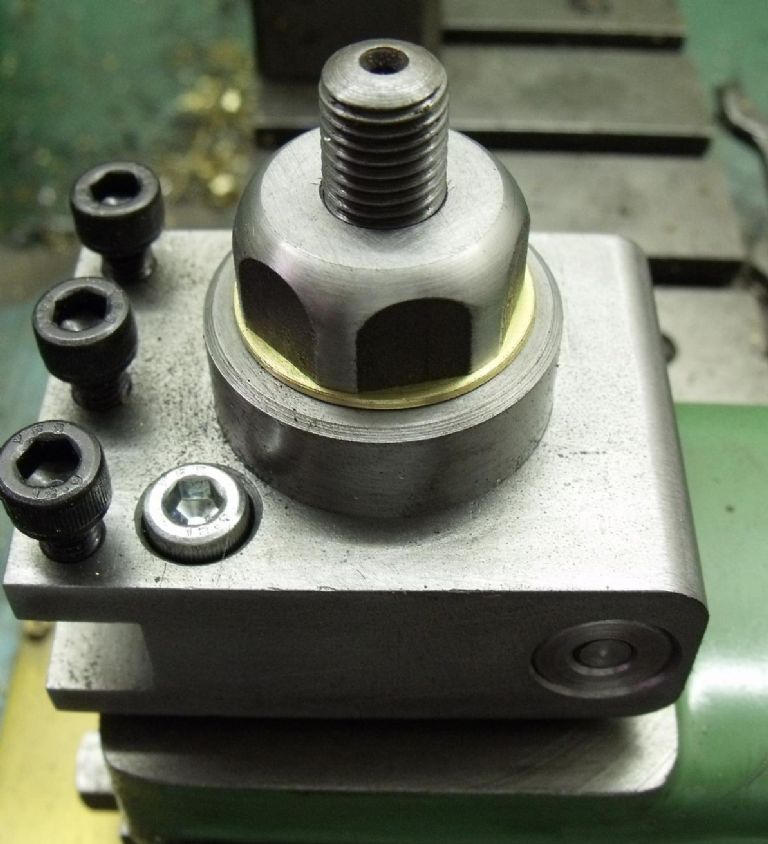

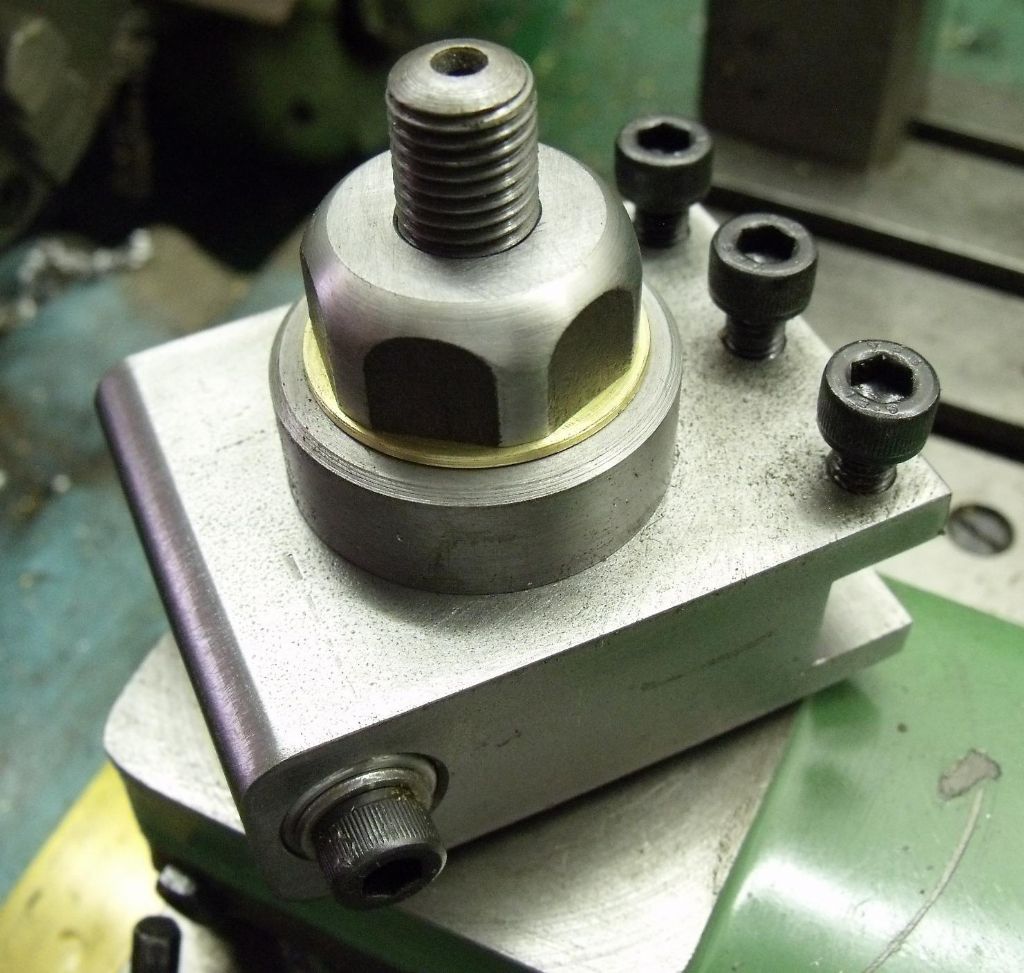

A rear-tool post is a simple solid lump of metal bolted direct to the saddle. In comparison front tool-posts are towering, spindly affairs that bend. QCTPs are extra bad because the cartridges add extra overhang. Parting-off with a QCTP is a little like going off-road in a Porsche – not what sports cars are good at!

Basically any hefty lump of metal configured as a rear tool-post whizzes all over the best QCTP available when parting off. Of course, front-tool posts and QCTPs are better for almost everything else! By the by, your QCTP may be fit for purpose whoever made it. Do the cartridges sit firmly and adjust OK? Unless it doesn't work effectively, buying 'better' is a waste of money – an unforgivable sin in engineering! Test it action, and make an evidence based decision before replacing it.

Ideally, the lathe is run in reverse when parting-off from the back, but that's unwise on a Myford even though it's a 'quality brand'. It has a screw-on chuck, and even the very best Pratt-Burnerd is liable to come off in reverse! Never mind notions of quality the combination of screw-on chuck and reverse running isn't 'fit for purpose'. (Not a big problem – mount the cutter upside down.)

Dave

John Haine.