My guess is swapping the wires won't cause magic smoke or reverse the motor. But I don't know for sure!

I think it's a capacitor start and run motor where the start and run windings are identical and one end of each is wired together inside the motor and brought out to terminal C,

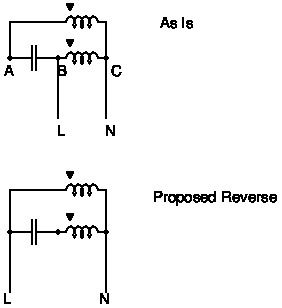

The circuit 'as is' and with the proposed change could be:

Swapping just the capacitor as shown in the lower circuit risks magic smoke because it depends on how beefy the top winding is, and we don't know. No problem if both windings are physically identical, but the capacitor connected winding might be wound with lighter gauge wire in expectation the current through it is limited by the reactance of the capacitor.

The reason I don't think swapping the capacitor will reverse the motor is that the start of the two windings, marked by solid filled triangles, isn't changed by moving the live connection, so current still flows in the same direction in both coils. As moving the capacitor doesn't change the direction of the current, I think the magnetic fields flow in the same direction, albeit the phase is different. Therefore I expect the motor to rotate in the same direction, and possibly be reluctant to start.

To get the motor to reverse, I'm fairly sure one of the windings has to be reversed. This can only be done by opening the motor up, finding the join, separating the two windings, and swapping one of them over.

Dave

Edited By SillyOldDuffer on 07/07/2022 12:15:58

Robert Atkinson 2.

Robert Atkinson 2.