Michael,

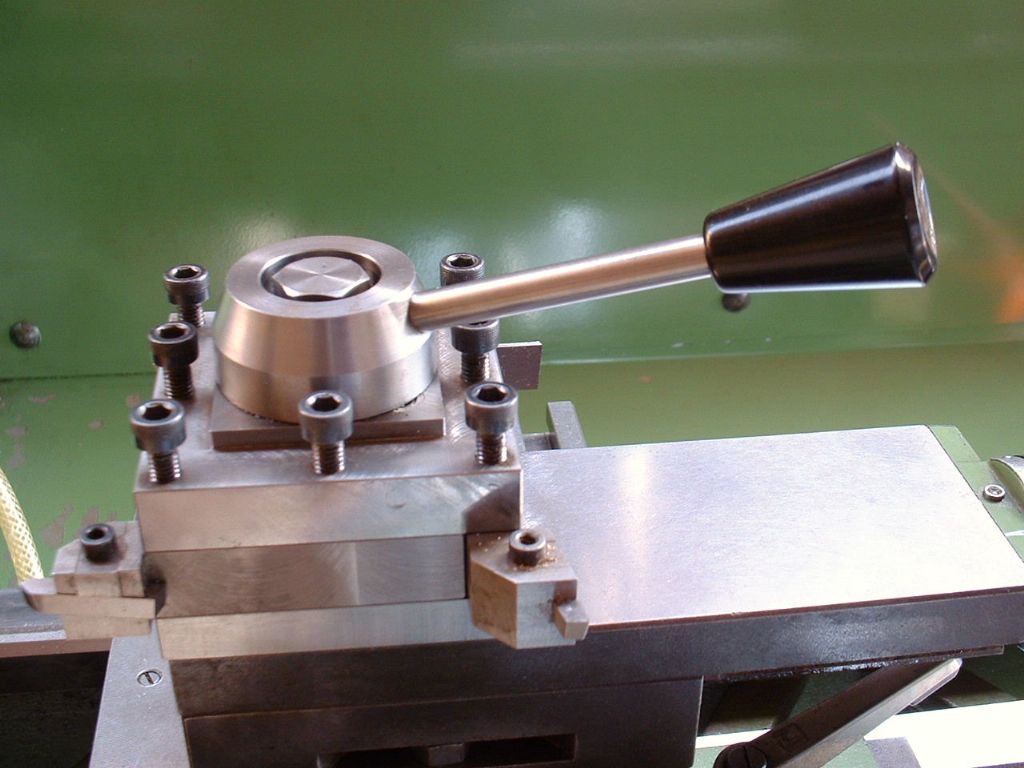

In this area you will get nearly as many opinions as there are ME's. As usual when discussing these things, the size of lathe and type of work being undertaken is rarely mentioned. There are many here who will advocate QCTH (and how many 'dozen' holders you need) and I'm sure that many find them very convenient. But the fact is that the good quality QCTH system can be quite expensive, especially if buying multiple holders.

This debate has raged for many years but I think it is interesting that most of the "Gurus" of model engineering (GHT, Tubal Cain, Ian Bradley and others) advocated simpler methods for the "amateur". Of course these were different times (and different pockets)

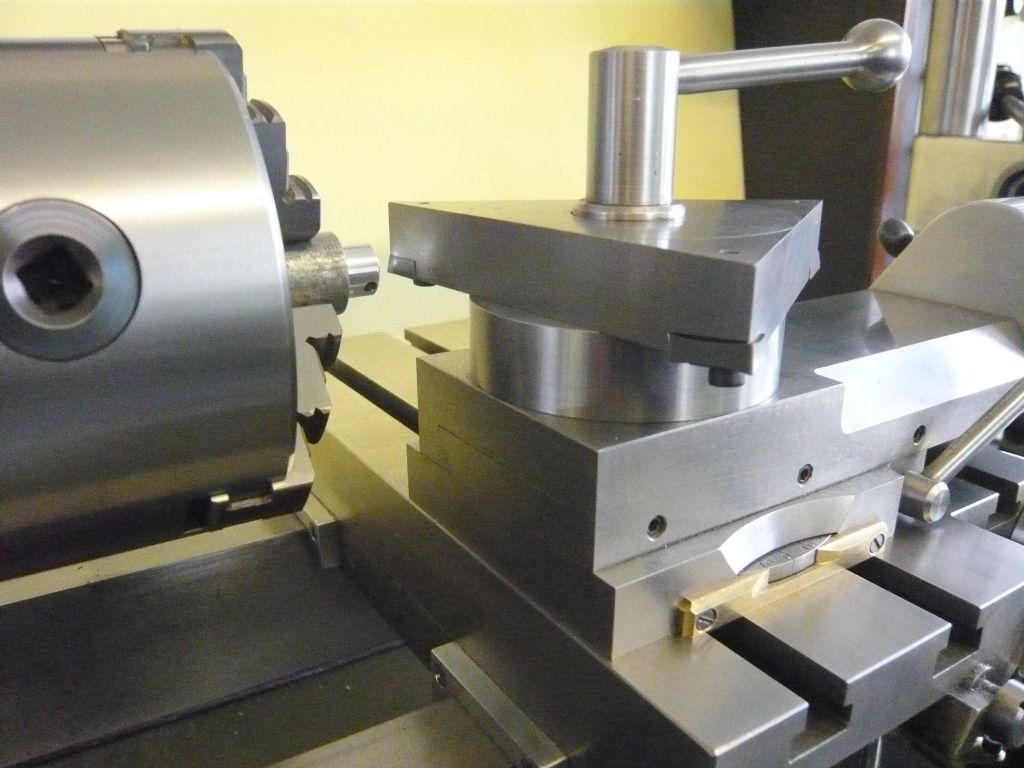

On my Super 7 I still mainly use 'single' tool holders, machined many years ago from castings that CES used to sell (which they unfortunately do not sell these days). My first QCTH was a Chinese economy version that came with my 2.5" EW lathe – and I now know it was one of the reasons that I struggled to get good work out of the EW initially, because of excessive tool overhang.

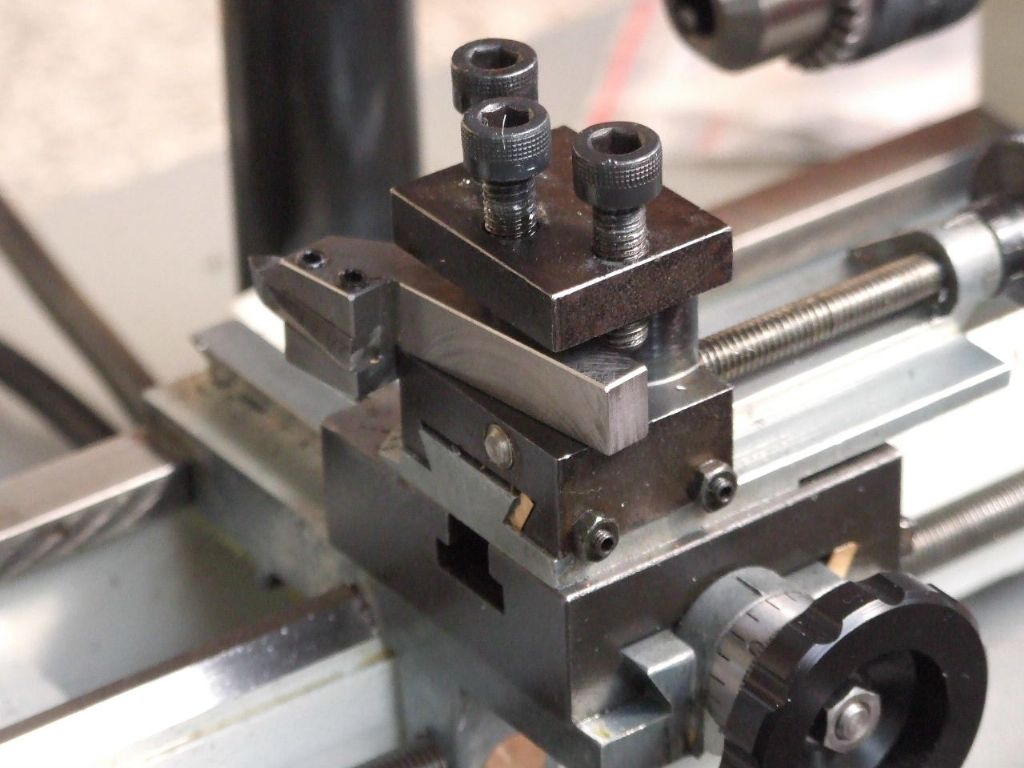

For some time now on the EW, I've routinely worked without the top slide fitted – using instead a simple steel mounting block directly on the boring table. This has improved things generally but the QCTH is really still a bit too big and I only had a few tool holders (so had to swop between my brass and steel tooling). The question became – do I 'invest' in more tool holders or look for a different solution?.

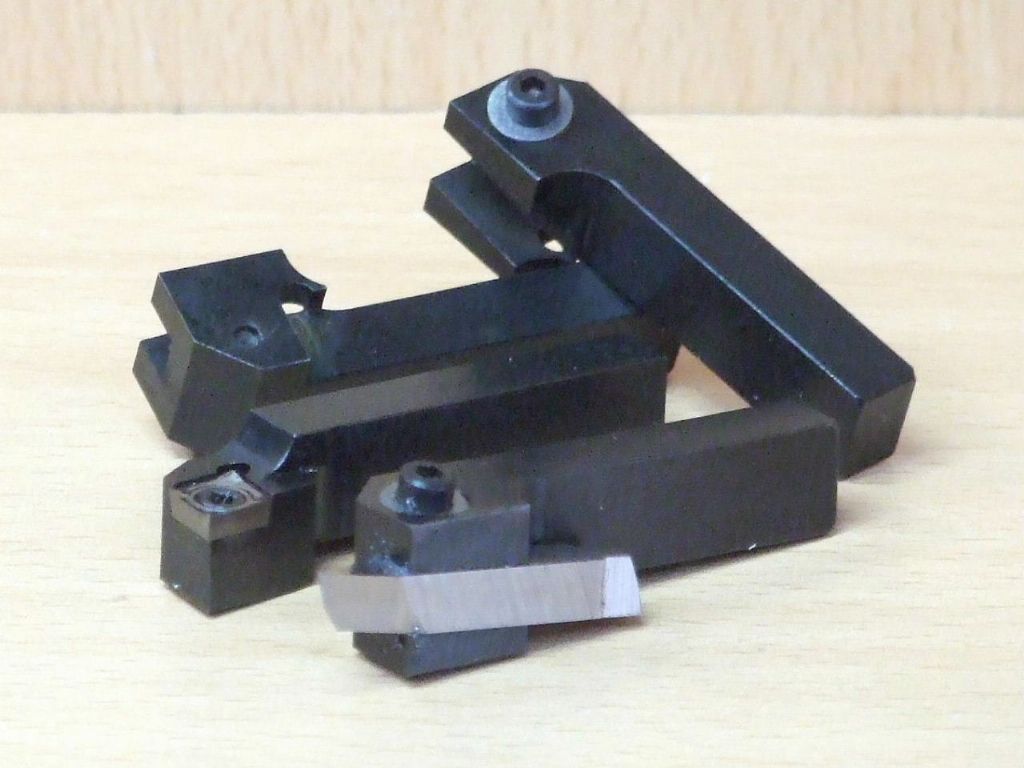

I went through my old ME/MEWs and looked at all the tool holder designs I could find. I was thinking of making smaller versions of the CES type holders (there have been several similar designs published) when I read a set of articles by Dr RM Rose (ME in the 70's). He advocated a very simple tool holding block and stated why he felt they were ideal for his kind of work.

I cannot report on the truth of his views just yet but the material has been purchased and a number of 'blanks' machined to size. Once I've opened up my 'summer' workshop – the shaper will make short work of the rest. I will use different holders for my brass and steel tooling, as well as make some specials for boring bars and parting tools.

To go back to my original point, I am making these holders for a 'small' lathe – which is generally used to make 'small' things. I do not require a production environment as most of my work is one-off. So Dr Roses solution will (I think) suit my EW needs very well. They clearly would not suit everyone.

Regards,

IanT

Graham Meek.