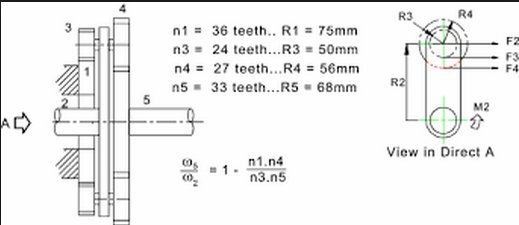

Calculating Epicyclic/Planetary gear ratio

Calculating Epicyclic/Planetary gear ratio

- This topic has 27 replies, 12 voices, and was last updated 23 May 2016 at 18:35 by

Nicholas Lee.

- Please log in to reply to this topic. Registering is free and easy using the links on the menu at the top of this page.

Latest Replies

Viewing 25 topics - 1 through 25 (of 25 total)

-

- Topic

- Voices

- Last Post

Viewing 25 topics - 1 through 25 (of 25 total)

Latest Issue

Newsletter Sign-up

Latest Replies

- Some help with a Cowells speed controller needed.

- Armortek series 1 landrover kit

- Boiler Examinations: 7-yearly External Query

- 24cc DIESEL ENGINE FROM SOLID

- Emco FB2 and Maximat Mill?

- Anyone know about wells and Victorian plumbing?

- Bending EN24t

- Fitting DRO to Myford VME mill.

- minimag set up

- Lantern Pinion

Shame about the £35 postage from china. In future it might be an idea to get people to club together to buy in bulk to reduce unit cost for shipping.

Shame about the £35 postage from china. In future it might be an idea to get people to club together to buy in bulk to reduce unit cost for shipping.