Always best to start with what CAD will be used for by the owner!

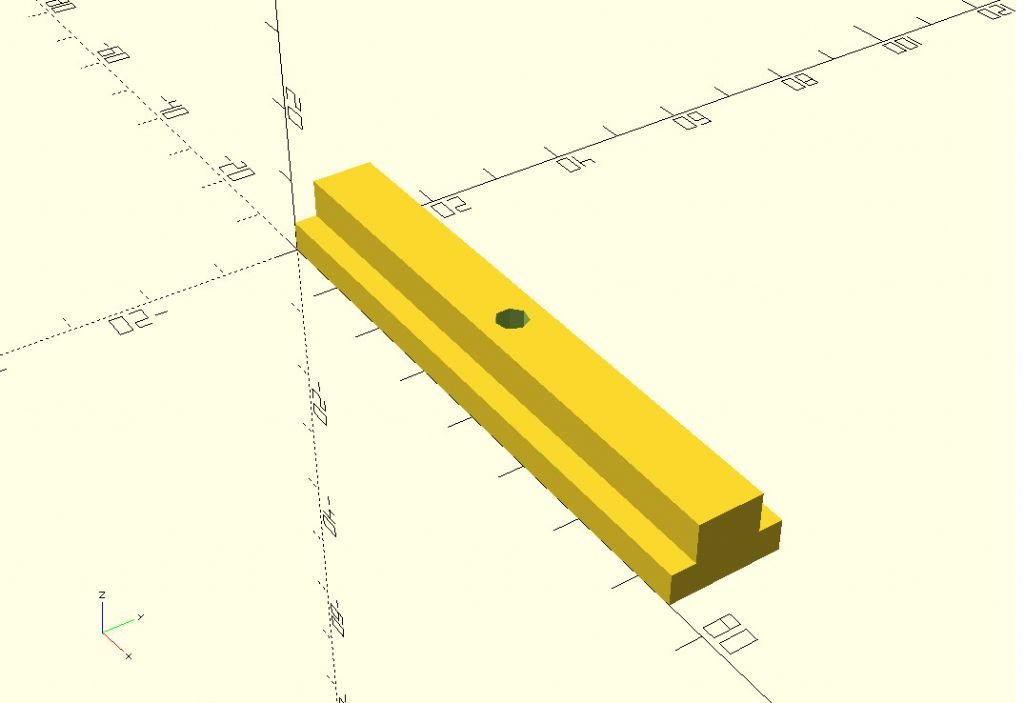

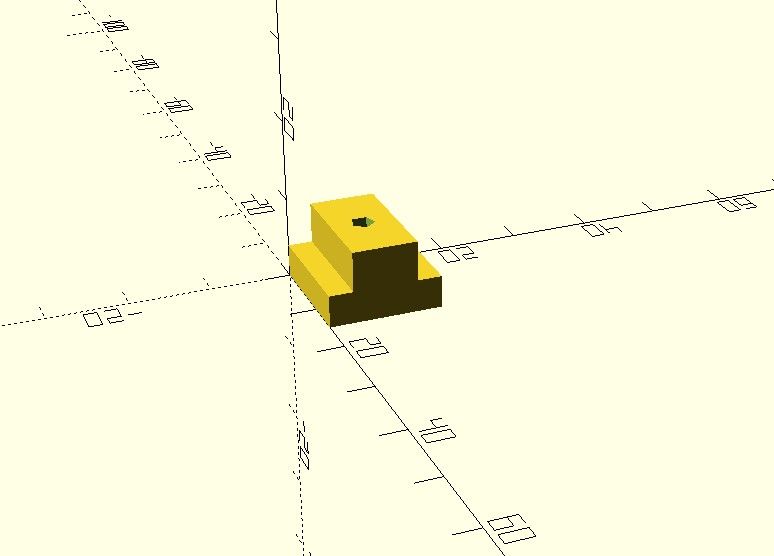

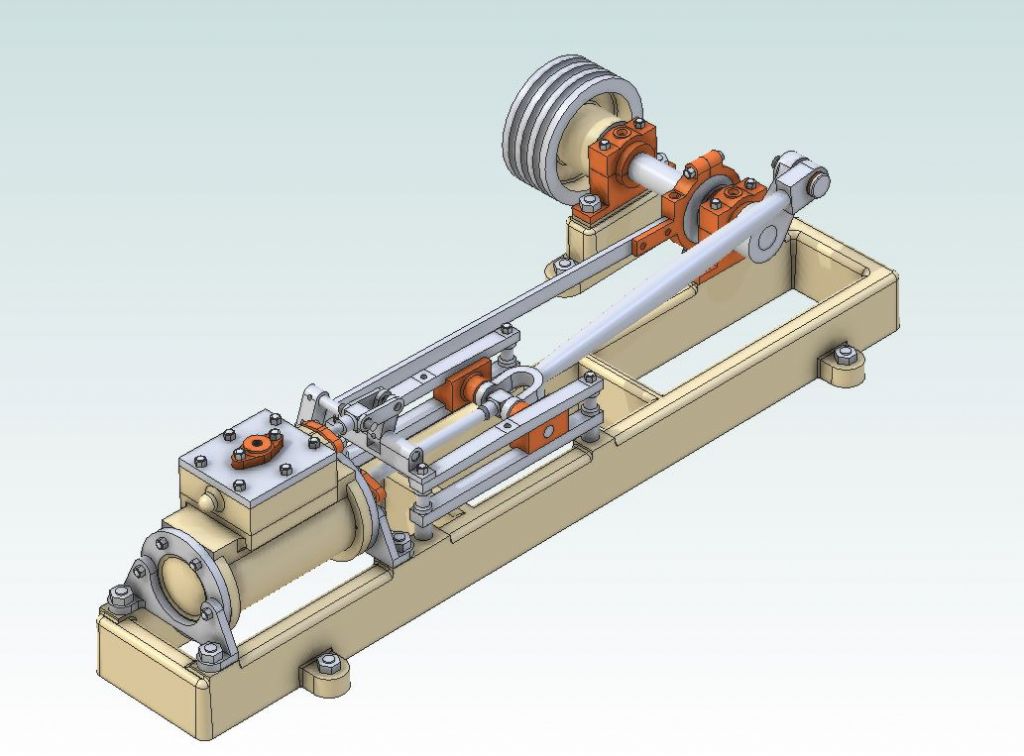

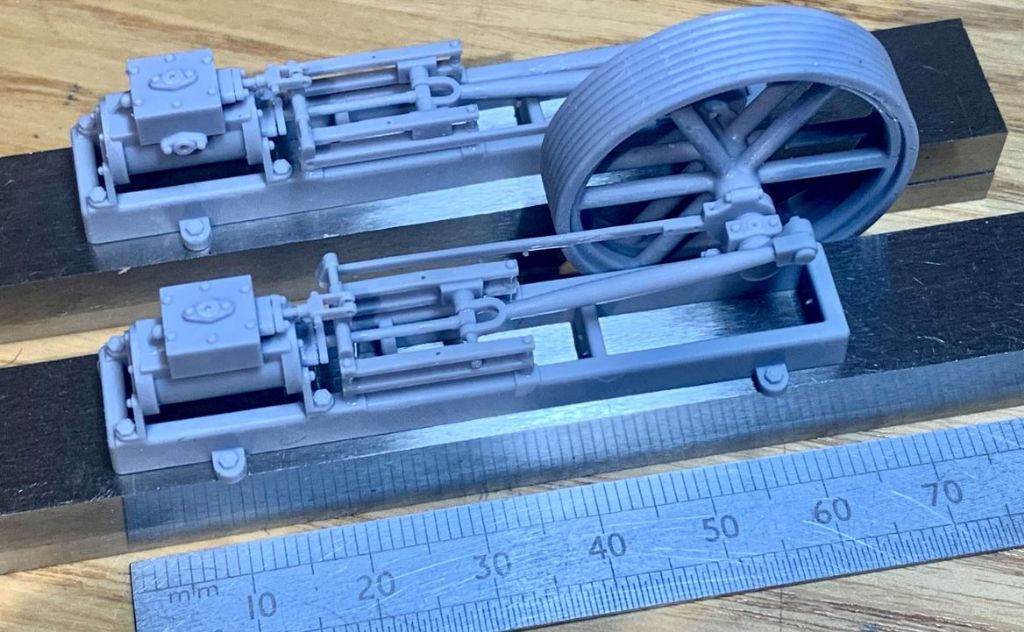

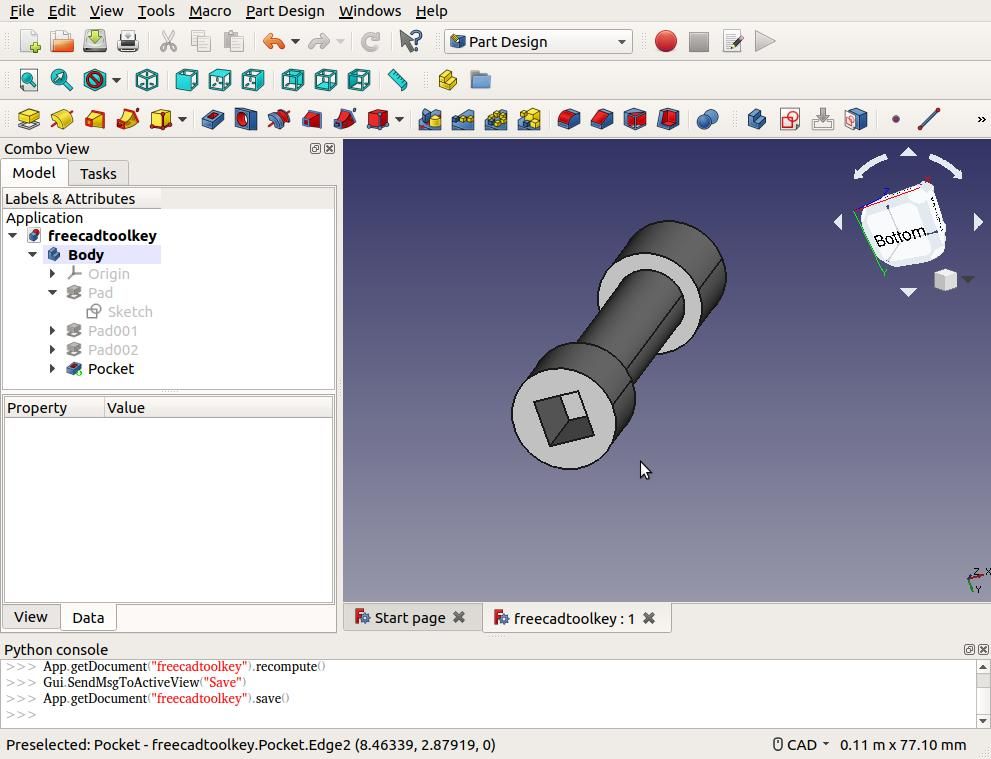

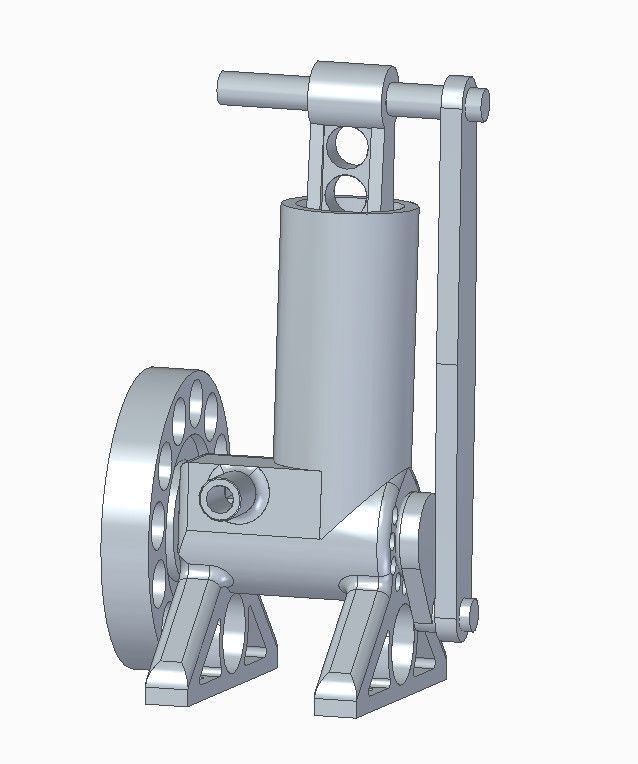

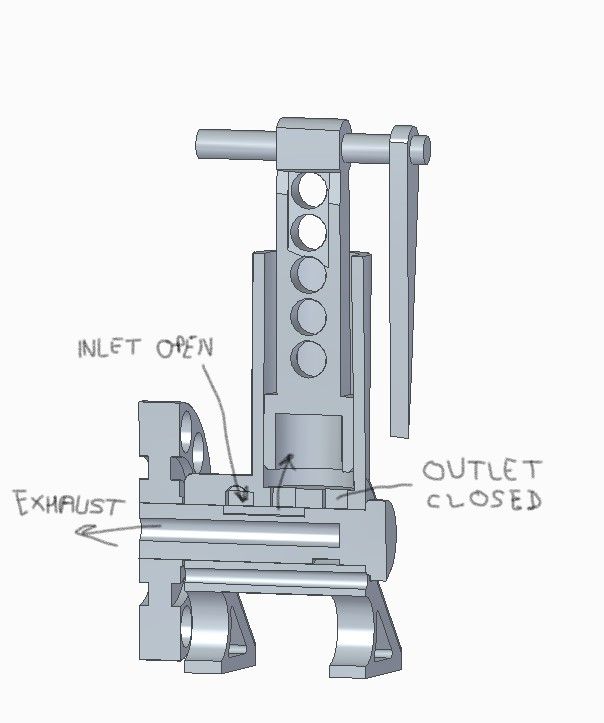

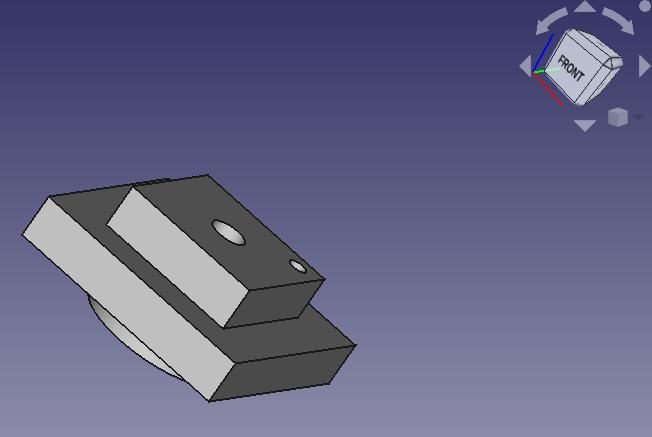

For 3D printing and single parts I mostly use FreeCAD, which really is completely free. Downside, it covers a lot of different CAD methods, they're all a bit experimental (crashes occasionally), and not necessarily compatible with each other! However, for 3D printing and Mechanical Engineering the FreeCAD "Parts Design" Workbench works well and does all the basics. I wrote a 'Get Started' thread in 2019 which can be followed to get a feel for how Part Design works without getting entangled with the rest. Good for 'Solid Model' objects like this, which can be metalworked or 3D printed:

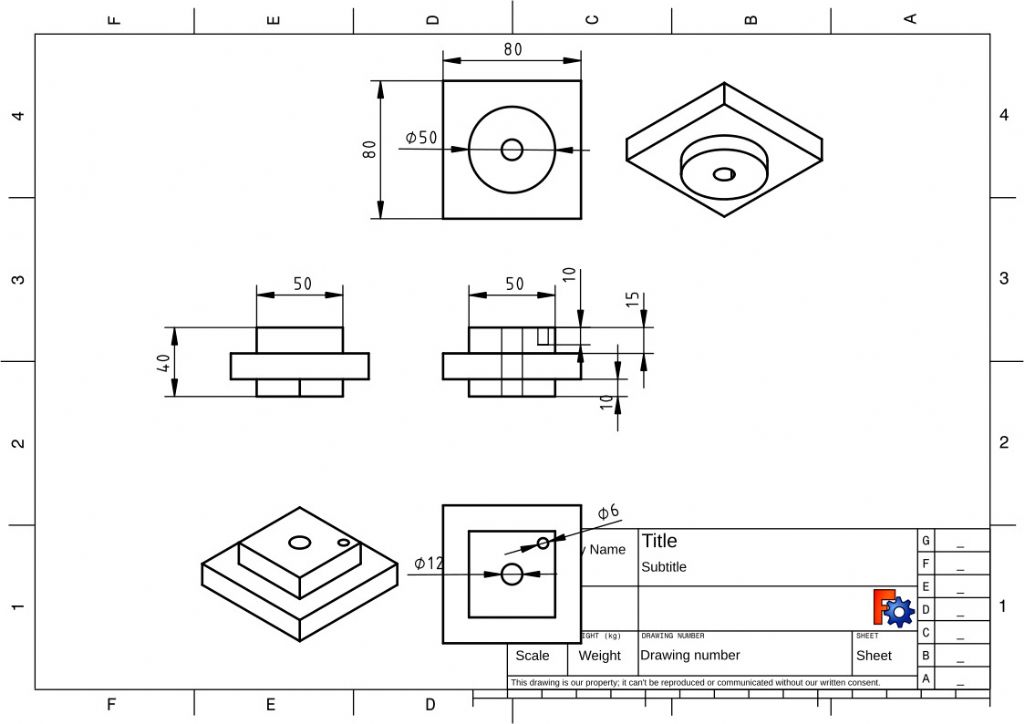

FreeCAD also has a Technical Drawing workbench which creates dimensioned first angle or third angle projections from 3D parts: these are important when the part is made manually rather than CNC or 3D-printed/

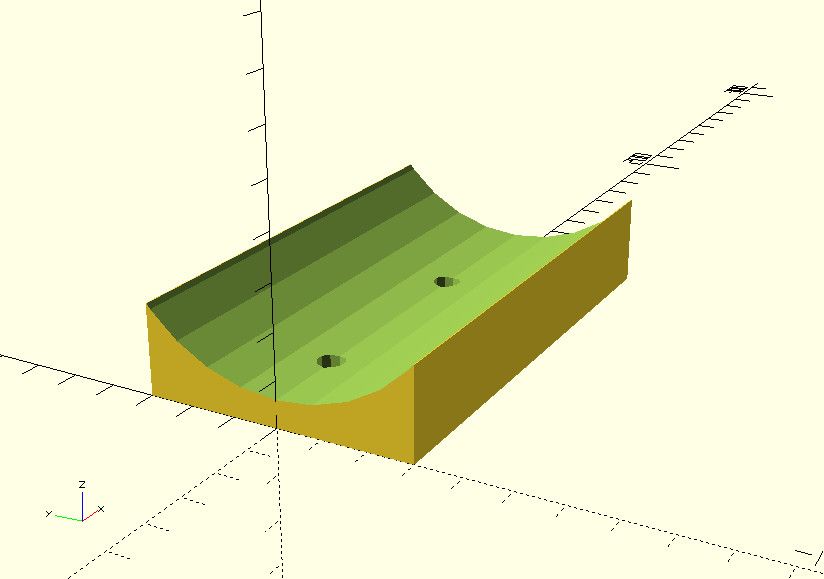

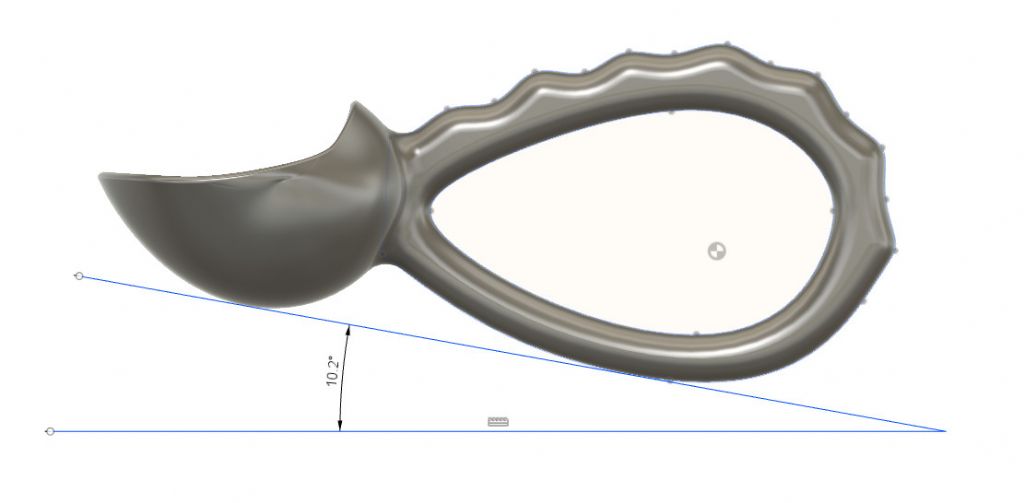

Blowlamp has recently drawn our attention to MOI (paid for, not too expensive), which seems fairly easy to drive. (But beware, CAD tools aren't simple.). Judging by Blowlamp's videos MOI can do much the same as FreeCAD Part Bench, but not I think, produce dimensioned technical drawings on paper. MOI has good 'Surface Model' support which is important for producing curvy objects like like this:

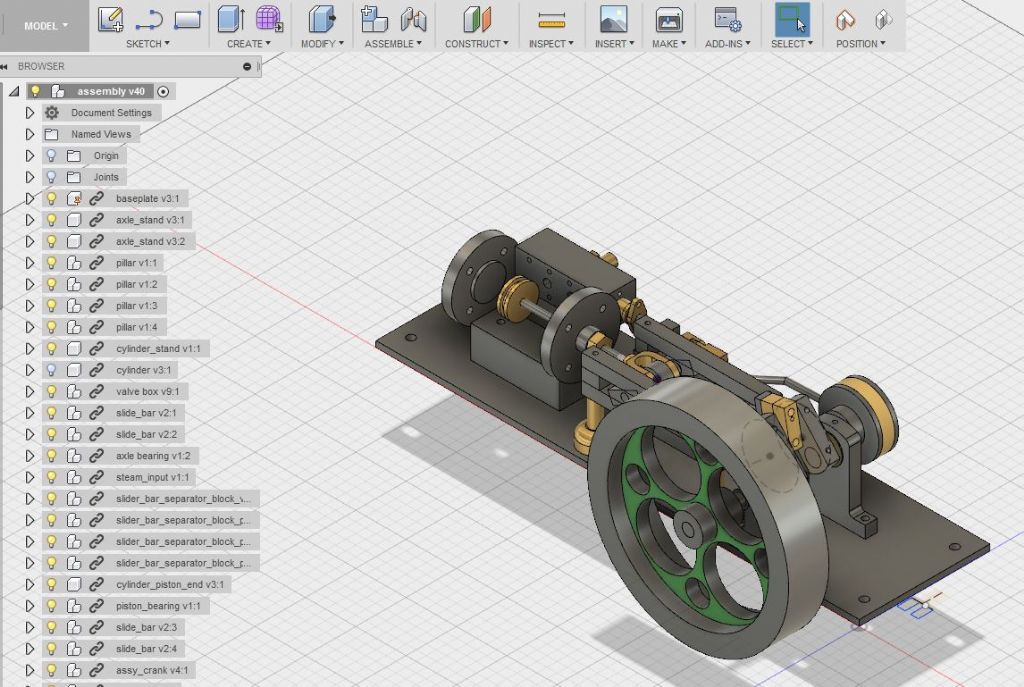

Fusion 360 works in a similar way to FreeCAD but is slicker, mostly consistent, and more complete. The completeness includes Assembly, that is models consisting of multiple jointed parts:

I found it easiest to learn, perhaps because it works in a similar way to FreeCAD, which I already knew. However, Fusion is a cloud product, which has privacy and control implications, for example AutoDesk applied a 10 open file restriction to the hobby version. Not a show-stopper but quite annoying.

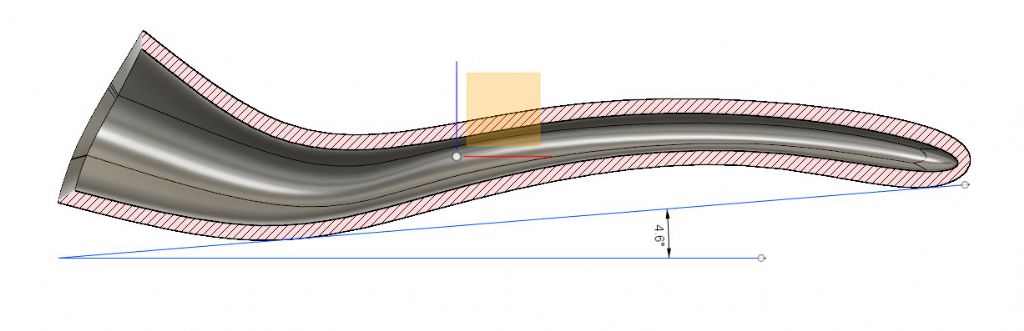

For that reason I switched to Solid Edge. Like Fusion, SE is also 'full function', able to do Surface Modelling, Sheet-metal, and Assembly, but it's an older product and the interface isn't quite so slick. The product also works in two modes, which is confusing. Ordered Mode is like Fusion and FreeCAD, that is the model is the end result of a step by step history. So if a hole needs to be moved, the operator finds where it was created in the history, alters it, and the change ripples forward through the model. All good unless the new hole breaks something else on the way! Synchronous avoids that by allowing the hole to be moved in the current model: it's very natural. However, it destroys the history, which can cause trouble too. Mostly though, Synchronous is preferred to Ordered, unless it doesn't work! SE works very well, and Synchronous is hot stuff, but I found it harder to learn than Fusion.

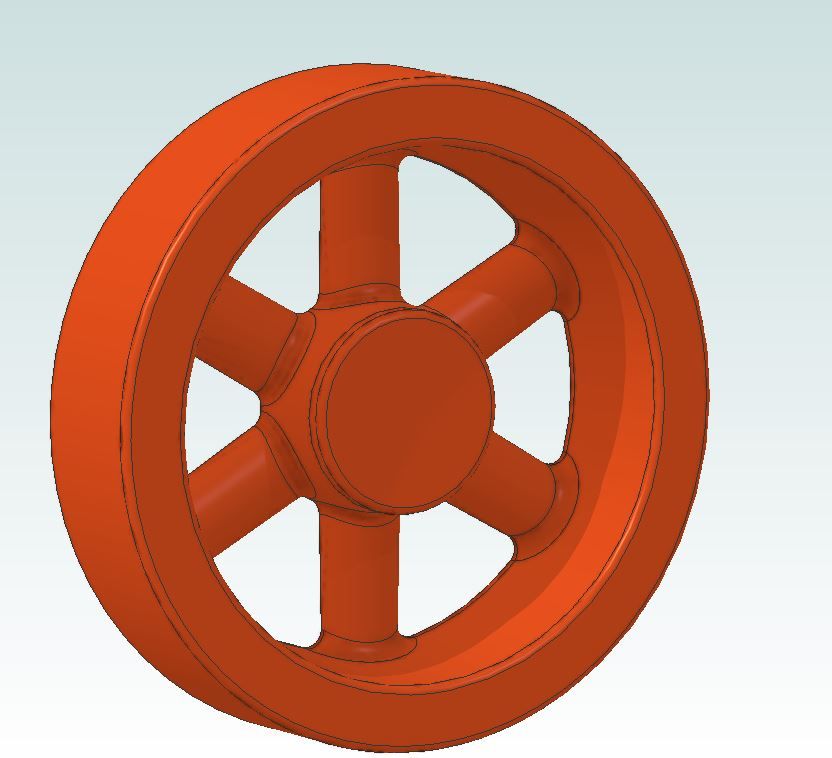

This is a 3D-printed engine in SE, an assembly of many individual parts with joint constraints. The model animates without parts colliding, but the real one doesn't because friction is high and the plastic bends. Apply enough compressed air to overcome piston stiction and it twists off the conrod and hits the ceiling. I think a metal version might work.

I'd recommend sticking with Fusion, SE, FreeCAD, or Alibre (covered in a MEW series) because several forum members use them and can answer questions. We have a member struggling with TurboCAD at the moment, and part of his problem is only one other member knows TC well enough to give good answers.

Dave

Edited By SillyOldDuffer on 17/04/2023 10:00:52

Edited By SillyOldDuffer on 17/04/2023 10:05:37

Gary Wooding.

Gary Wooding.