Posted by David-Clark 1 on 05/04/2022 12:00:58:

…

This sort of function library might be useful to programmers but for all I know, do CNC users use software programs to machine everything and no programming is involved? In which case, is there much need for CNC in MEW?

You tell me what you would like to learn in MEW and I will see what I can do. What CAD and/or CAM programs do forum members use nowadays?

I don't use CNC on metal but find 3D printing very useful. When plastic parts are up to the job, 3D printing can manufacture them more or less directly from a 3D CAD model. Quite a lot of Model making could be done this way – parts for model railway layouts, Tram and Boat fittings, components, electronic enclosures, light mechanisms, and difficult shapes generally. Small parts of any complexity can be printed if they can be drawn. Not particularly suitable for making steam locomotives, but then blow torches, Myfords and rotary tables aren't ideal for making Quadcopters!

My interests lean towards design and experimental work rather than model making: more SMEE than LBSC. At the moment I'm exploring 3D printing as a design aid. Designing and developing a new metal mechanism consisting of several interrelated parts is difficult, and a lot of time is wasted making prototype parts in metal only to discover the shape or dimensions aren't quite right, or that the assembly interferes, or the design can be simplified by turning one part into two, or vice versa.

My process typically starts with a rough sketch – back of an envelope, or squared paper. I often develop complex shape ideas with a 2D drawing package (QCAD) because old-school drawing board technique is the bees-knees for capturing dimensions and layout accurately. Or, I go straight to a 3D CAD package and create the part in three dimensions by adding and removing a series of shapes, each shape being defined by a simple 2D sketch. Thinking in 3D is quite different from 2D, and it can take a lot of effort to unlearn 2D technique. But once grasped 3D, the technique is extremely powerful.

Both 3D-CAD packages I use can draw 2D projections which I can cut metal from manually in time honoured way. Or they can export a parts geometry as an STL file. 'Standard Triangle Language' is a computer generated description of a 3D object's outer surfaces. Not normally altered or written by humans, though it can be.

To do CAM, STL is usually translated into G-code by another program. G-code isn't really meant for humans either, but it can be edited manually if required.

For 3D Printing I use Cura, which is a 'slicer' producing the g-code telling my printer where to accurately squirt tiny blobs of molten plastic as necessary to create a solid representation of the 3D model. This is an additive CNC process done reasonably well with a desktop 3D printer costing a few hundred pounds.

Although slow, 3D printing is ideal for prototyping because it makes most parts faster than I can! 3D savings require the problem to be above a certain level of complexity – designing groups of closely related parts where my brain can't hold all the information, and everything has to be in the right place. Designs can be debugged and developed using automatically made plastic parts, not requiring me to plan a metal cutting workflow, or to apply my dubious metalworking skills, until I know the prototype is tickety-boo. Not true CAM because the final metal parts are still made by me with manual lathe and mill etc.

I don't do subtractive CAM, where a CNC machine creates shapes by cutting metal off, partly because I rarely need the facility, but mostly because I haven't caught the bug yet!

I use two different 3D-CAD packages.

FreeCAD is genuinely free (no charges), but is a slightly buggy development project, where certain features are missing, and many others aren't useful to Mechanical Engineers. Most useful for developing single parts because it can't do joints yet.

Fusion360 is a well-developed commercial product focussed on Mechanical Engineering. It does multipart assemblies and joints, intuitively I think. All the parts of an engine can be modelled, assembled together, and animated as a working engine. For prototyping, a good assembly function reduces the need for 3D-printing. Much to like in F360. Unfortunately, the full function version is no longer free to hobbyists: the free version is restricted in various ways to encourage users to buy the full version. Being a cloud product makes some users nervous about having their licences cancelled, or their proprietary designs being visible to AutoDesk, or hacked.

My main point is the value to Model Engineers of 3D-Printing from 3D-CAD, I think more people would gain from it than CNC milling, which because the latter is isn't the best way of knocking out a few parts. Cutting metal with CNC pays off if the shape requires a curved cutting path and when between 10 and several thousand parts are wanted. Often quicker to make a few parts manually than to set up a CNC machine. As most Model Engineers only make parts in small numbers, I suspect CNC will only actively appeal to a smallish subset of the community.

Could be wrong. Again!

Dave

Edited By JasonB on 05/04/2022 16:04:21

Another JohnS.

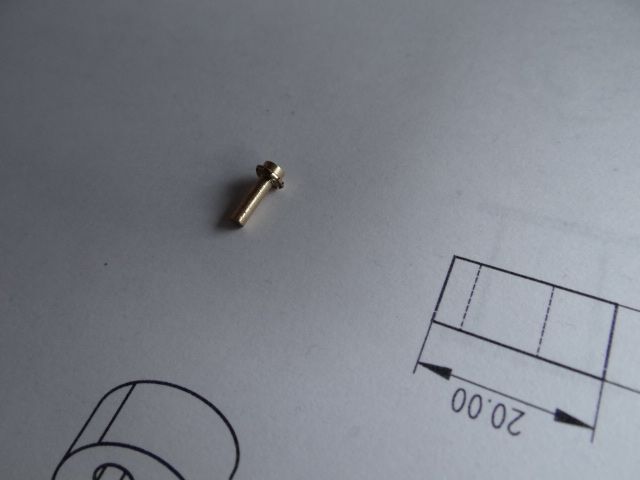

![20220402_154631[1].jpg 20220402_154631[1].jpg](/wp-content/uploads/sites/4/images/member_albums/44290/906313.jpg)