Hi Andrew

Like what you have done to date as it puts a different perspective on things. I have been cogitating on this and realise it is not simply a case of points closing/opening etc. So I have a new take on this and it takes on board some of what you have said and some of my bits as well, couldn't leave them out could I  .

.

It goes like this:

Initially ignoring the HT winding

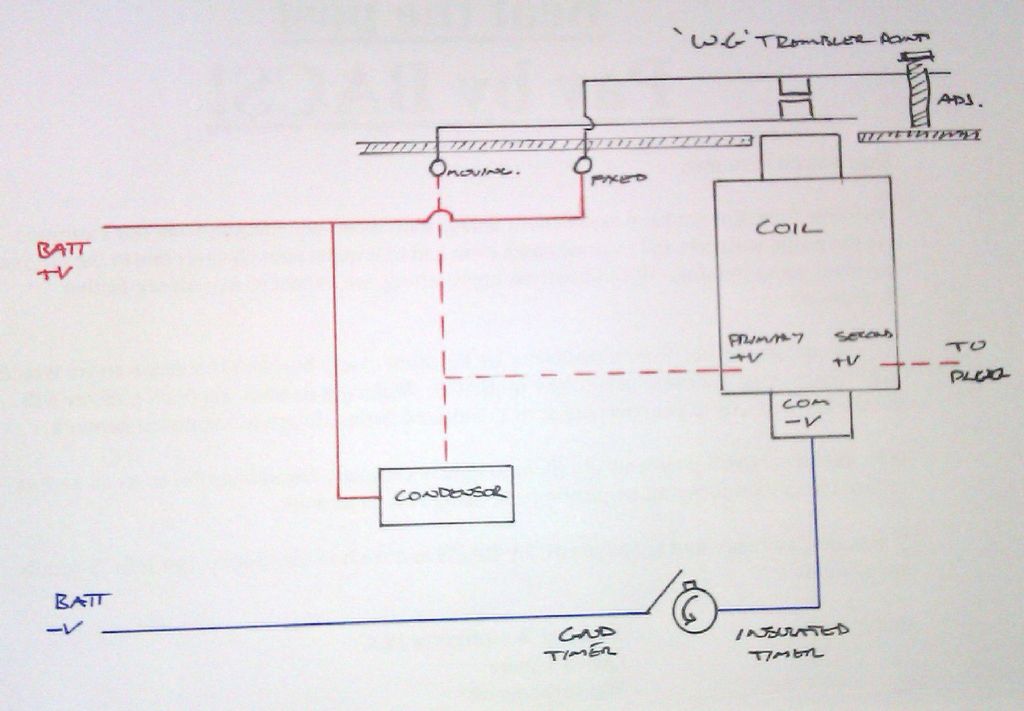

a. Points are closed and the current flowing through the LT, low tension coil, generates a magnetic flux in the core; its assumed that the core is not saturated at this stage.

b. Points open and the capacitor in its discharged state is effectively connected between the LT coil and earth. The capacitor charges and draws more current through the LT coil increasing the magnetic flux. The LC product sets the effective resonant frequency of this combination, see Andrew's posts and graphs, and this effectively dictates the rise time of the charging pulse i.e low value capacitor fast rise and higher value capacitor lower rise time.

c. The value of the capacitor has another effect and this is the Q.This is not the same Q that Andrew refers to in his post but as in Q=CV in coulombs. This can, after a bit of integration, be described in W watts or available energy.

d. Bringing the HT winding back into the equation. The HT winding is mounted on the same core as the LT winding and so is affected by this increase in field flux. When the flux increases the HT coils generates a voltage in response to this and I think that this voltage will be dependant on the rate of change of flux that the coil is subjected to, my original argument  regarding V=dv/dt x h.

regarding V=dv/dt x h.

If the capacitor has to small value then although the rise time will be fast there will not be enough energy Q=CV either to maintain or even initiate the ionisation of the spark gap, conversely if the capacitor value is to high then while there is plenty of energy the rise time will be too slow to generate the required voltage to initiate ionisation.

The graph in the article I referred to shows the initial spike when the contacts open, similar to that in Andrew's simulation, followed by a relatively low voltage plateau during the spark burn time. I think that the near constant voltage across the capacitor is when the capacitor is charging and drawing current through the LT winding to maintain flux change required to sustain the ionisation.

This may be wildly out but seems fairly logical after a couple of glasses of red wine supped in the garden on a rare warm evening.

Looking forward to the results of Andrew tests.

Cheers

Martin

Edited By Martin W on 25/07/2012 00:35:07

Martin W.