Dave Halford –

My thoughts:

1. If I have a milling machine, surely I won't need a separate drill?

2. That said…

+Ves:

Powerful motor: 350w

Nice big chuck: 13mm

Sensible weight: 18Kg

-Ves:

Speed: 600-2600RPM is a bit slow for small drilling.

Cost: £86.64(suspiciously cheap!)

I'm sure it's a BAD idea, but what would actually happen if I tried to mill (i.e. cut horizontally with it?)

From looking at it, I suppose the main shaft will flex a bit, making it inaccurate. And maybe the bearings aren't designed to cope with lateral forces… But at least it's got a reasonably powerful motor (350w), and it's not too heavy (18Kg)

JasonB – thank you (genuinely) for the lesson on cutting speeds… esp. in metric. In the past I have ducked the issue but going forwards, I shall use that!

That said, I just looked up the cutting speed for mild steel is quoted as: "3–38 meters per minute".

So for 6mm – which is the probably the largest diameter I would hope to cut – we have:

3m/min ==> 159 rpm

38m/min ==> 2,016 rpm

…which seems like an incredibly wide range!

But "with coolant" it's "6–7 m/min" ==> c 345 RPM

[Btw, does this mean when cutting slower coolant is more important?]

I also looked up the cutting speed for aluminium "122-305" m/min

122 m/min ==> 6,472 rpm

304m/min ==> 16,181 rpm

Stainless Steel (300 & 400 series) cutting speed: "23–40" m/min

23 m/min ==> 1,220 rpm

40 m/min ==> 2,122 rpm

Polyethylene cutting speed:

"12" m/min ==> 637rpm

Conclusion:

I don't think I'm going to use anything less than 600 rpm, but form smaller stuff (e.g. 1mm cuts), I really need at least 10,000 rpm.

WHERE I'VE GOT TO (so far)

1. BRANDS

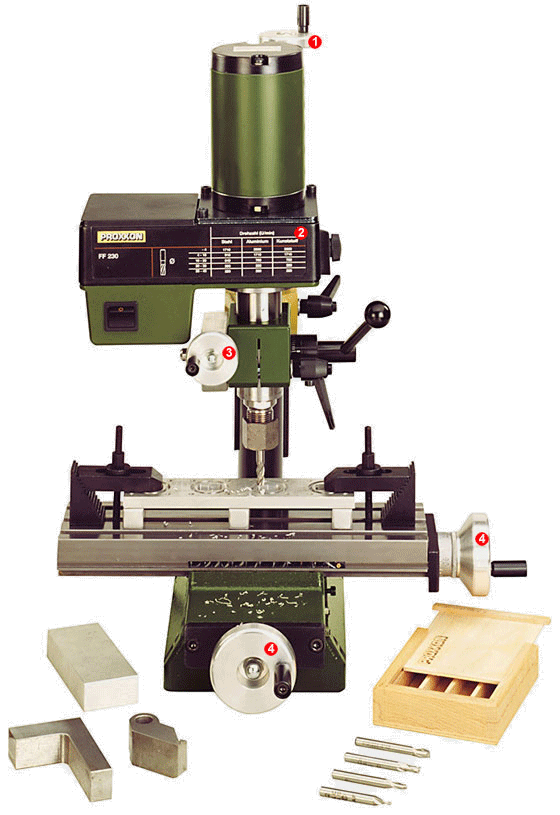

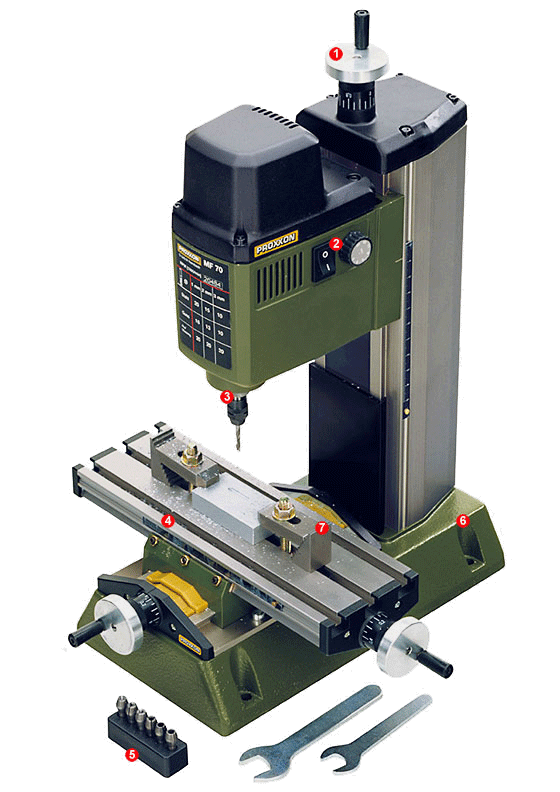

1.1. PROXXON

Proxxon clearly has its detractors & haters(!) but having bought one I think the quality is OK-ish, even if it is painfully over-priced. Either way I've not seen much else for very small (i.e. very high RPM) work.

– The MF 70 is fast 5,000 to 20,000 rpm a but a bit of a toy (very, very small cuts only)

– The FF 230 is a reasonable weight (17Kg) but too slow (up to 2200rpm)

– The FF 500/BL is stupidly expensive (£1,808.15)

– Personally I don't mind Proxxon, but would prefer not.

1.2. SHERLINE

Quality looks very good, but hard to buy here in the UK.

RPM is very slow "70 to 2800 RPM"

Motor also looks rather weak ("60 watts power output)

1.3. SEIG

– X0 Digital Micro Mill (14Kg, 150Watts, "0 to 5,000" RPM) ==> but discontinued

– SX1LP "HiTorque Mill" (50Kg, 250Watts, "100-5000 rpm) ==> 50Kg is too heavy

4. WEIGHT

I was hoping to find a milling machine that is half way between the 7kg Proxxon MF 70 and the 50Kg SIEG X1LP.

Maybe spec-wise 20KG is unrealistic, but I'm never going to lift a 50Kg machine on and off a shelf very day.

==> Compromise 30Kg?

3. SPEEDS

I was hoping to find a milling machine that can do both very fine work and "as large diameters as is reasonable for the weight".

Running the numbers, cutting mild steel 1mm at 25m/min ==> 8,000 rpm

Although to be realistic 6mm may be pushing it, as JasonB has pointed out, for 6mm diameter cutting reasonable speed would be 1320rpm. Given that I'm going to want to cut plastic (slower cutting ) and aluminium (faster cutting)

So on balance I now think a reasonable target RPM range would be 600 to 10,000 rpm

MY CONCLUSION (so far)

– I need a machine that is designed to do milling

– Weight up to 30Kg if necessary, definitely not 50Kg

– Speed range: 600 to 10,0000 rpm

Does such a machine exist? Maybe the Sherline – if I can acquire one here in the UK – but with the conversion kit

J

John Gray 7.

["5400 (5410)"] looks like a nice, rather elegant piece of kit. Sensible weight at: 18Kg. The table seems rather narrow at just 70mm deep (but maybe there is a good reason for that??)

["5400 (5410)"] looks like a nice, rather elegant piece of kit. Sensible weight at: 18Kg. The table seems rather narrow at just 70mm deep (but maybe there is a good reason for that??)