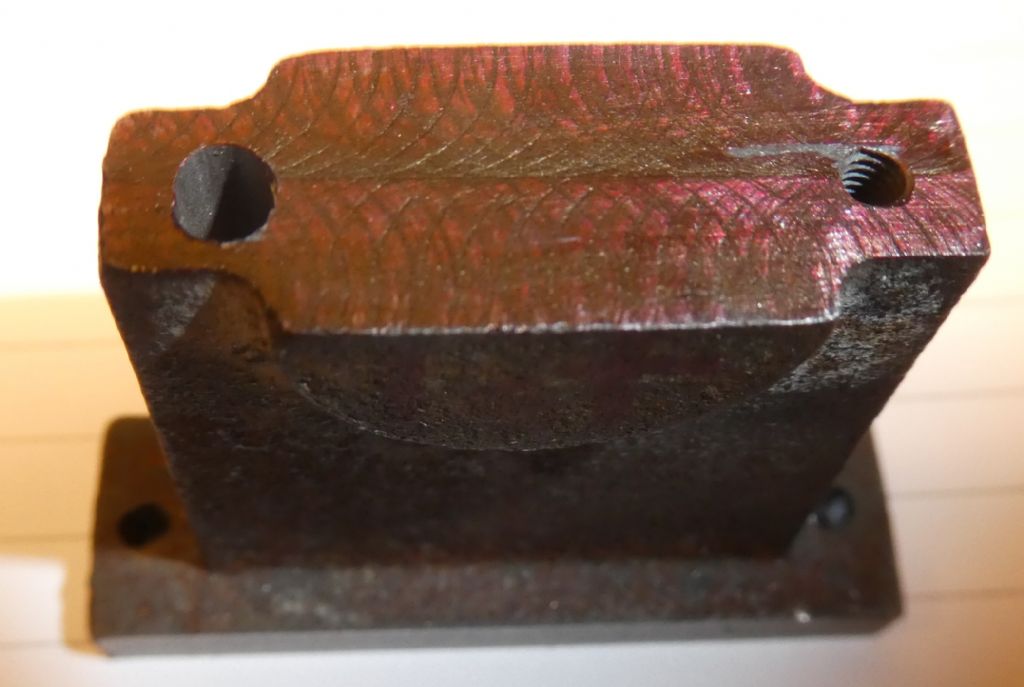

I am in the (slow) process of building a Double Tangye stationary steam engine using a set of second hand castings. They have been part machined – and not particularly well either!

A lot of the re-work involves opening out poorly positioned holes, re-drilling oversize and filling with loctited studs which can then be re-drilled in the correct position.

All was going well till this morning when I realised that one of my bearing standard castings had a busted 6BA tap stuck in the ‘ole.

Years ago I would have given it to my ‘oppo who would have spark eroded it out for me but these days I’m on my own – “so sort this one out mister” I thought!

First attempt to remove the tap was with a 3mm dia mounted point grinding wheel with nil result. Then I tried a similarly sized cheap diamond version, again, nil result. Both attempts were made using an old mini drill I had bought in a field on a Sunday morn earlier this summer. These days my old mitts are not steady enough to hold a dremel and I do not own a stand else I would have tried that method first. (I’ve put a stand on the shopping list).

I read on the forum recently that somebody (I cannot remember who, so apologies to that bod) had reminded me that carbide was quite capable of cutting HSS. It so happens that I had a part pack of ten cheap carbide engraving cutters earmarked for use for the odd engraving job on my small CNC mill.

Once again and with the drill still set at top speed of 8,500 rpm I bought the engraving cutter to bear on the broken tap and gave it some welly. It certainly made some progress before the tool bit shattered but “nil carborundum” as they say. I fitted a new cutter and had another go. The second cutter was starting to break up when it suddenly broke through and the busted tap was out. It was brutal, it was noisy but it got the dirty job done. I would not subject a nice new posh Proxxon to this sort of abuse but my three quid car boot special I consider fair game.

It just remains to open out the hole to 5mm and tap 6mm for yet another stud and my casting is saved.

I am confident that the high speed was the key to success – it must have been the closest I had been to producing plasma whilst “fettling”.

Rik

IanT.