This part is needed for my clock, with a pendulum is intended to swing in a low vacuum, as low pressure as I can manage.

The challenge is even a tiny leak will spoil the vacuum, and it needs to last for years because evacuating the chamber disturbs the pendulum and spoils the clock's accuracy.

The penetrator takes 6 1mm diameter bare copper wires from the electrical gubbins inside the vacuum out to an external microcontroller. The wires will fit through an 8 or 9mm diameter hole, at the moment an 8.5mm hole drilled through an M12 penetrator.

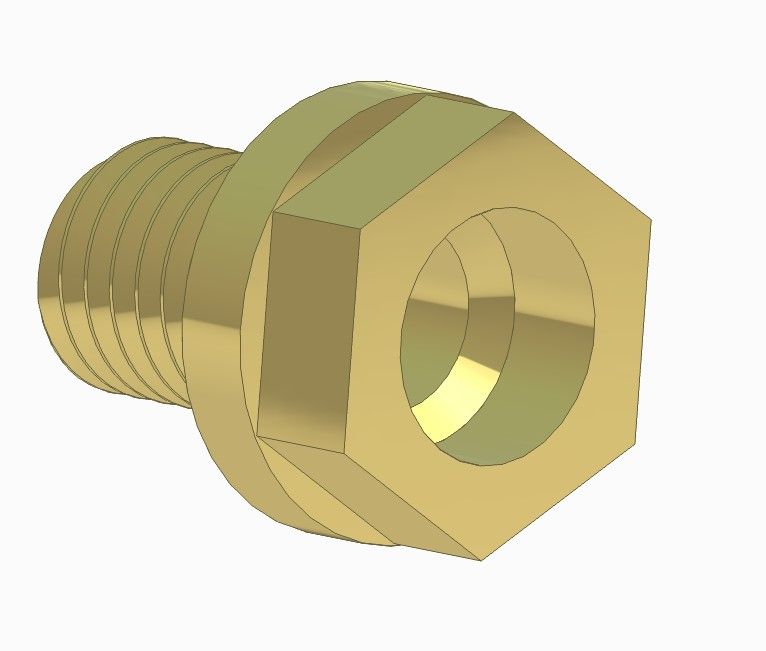

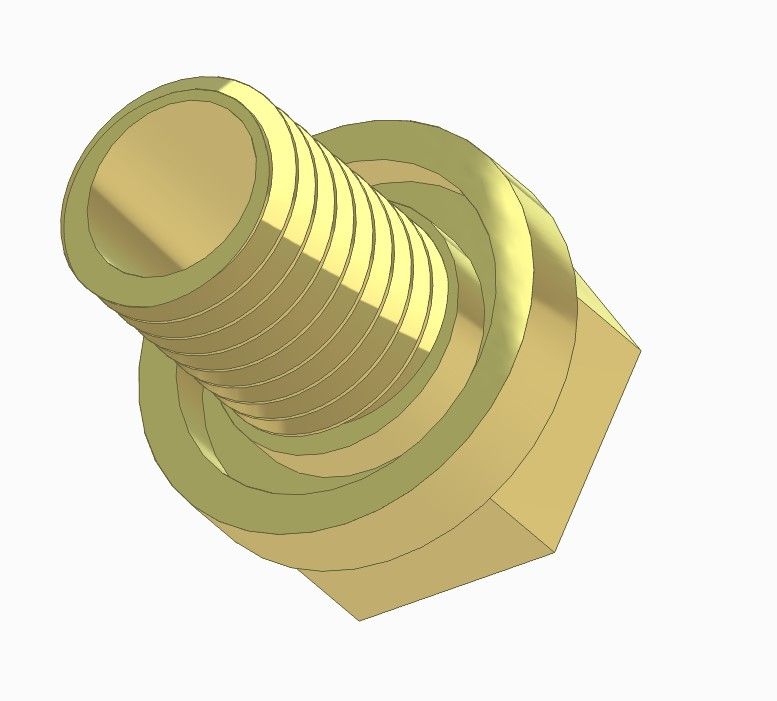

My design:

The 4mm groove in the flange is designed to take a 13 x 3.0mm O-ring. The exact position of the groove depends on from which side the pressure comes from. When the O-ring is squished down, the 1mm gap is on the high-pressure side, so the o-ring is pushed tighter by air pressure into the opposite wall.

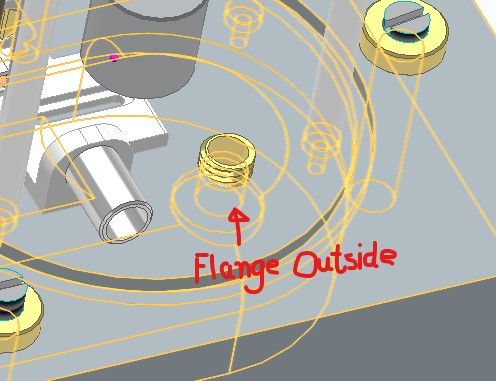

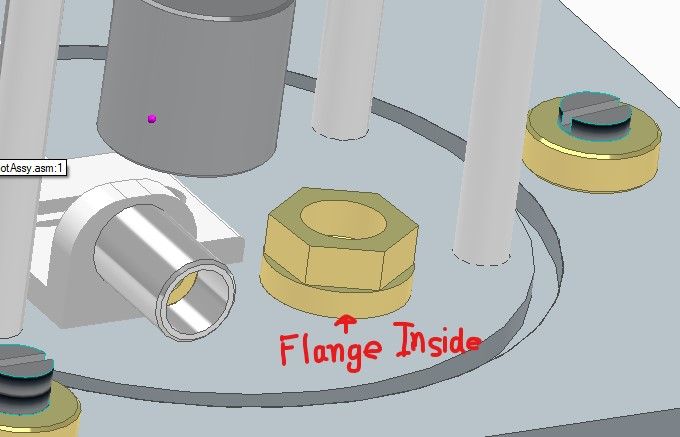

My first question, is should the o-ring be on the low-pressure side, in the vacuum, or on the high-pressure side:

My first thought was flange outside, but I'm veering to flange inside. Reason being I plan to use a thread sealer, which, being gooey, could be pushed up the thread and out into the vacuum container – there's nothing mechanical to stop it flowing. Other way round, with the flange inside, I guess the sealant is still pushed up the thread, but will be physically blocked at the top by the O-ring and flange.

Which side of the bulkhead the flange is mounted alters the design in two ways. The groove moves sideways by 1mm, and there's an internal step inside the penetrator to support the insulating compound against outside pressure.

Secondly, although I've assumed the penetrator should be made from Brass, is there any advantage in Aluminium, steel or plastic?

Thirdly, what should the insulator be made of? Something that can be poured into the hole around the wires. It needs to be electrically good, physically strong and non-gassy. Araldite is a contender but it's messy and might gas. Silicone sealant is weak and gassy – it emits Acetic Acid as it sets. I'm tempted to use Apiezon Wax W, which is a purpose made hard high temperature vacuum sealing wax. Only problem, £60 for a kilogram block.

What do the team think?

Dave

SillyOldDuffer.